Tensile Tester Shear Strength Production Facilities Overview and Key Insights

Understanding Tensile Testers and Shear Strength in Manufacturing

In the realm of manufacturing and material science, ensuring the quality and integrity of materials is paramount. One of the fundamental tests conducted to analyze material properties is the tensile test. This method is essential for determining the tensile strength and overall durability of materials used in various applications. However, another critical property often examined in conjunction with tensile strength is shear strength. This article delves into the importance of tensile testers in evaluating shear strength and their relevance in manufacturing processes.

What is Shear Strength?

Shear strength refers to the maximum stress a material can withstand when subjected to shear forces. Shear forces occur when a material is subjected to opposing forces that tend to slide one part of the material over another. Understanding shear strength is crucial, especially in applications where materials must resist forces that could lead to deformation, failure, or fracture.

The Role of Tensile Testers

Tensile testers, often known as universal testing machines, are designed to carry out various mechanical tests, including tensile, compressive, and shear tests. These machines apply a uniaxial force to a specimen, typically a standardized sample of the material, until it deforms or fractures. The data obtained from these tests are essential for engineers and material scientists, providing a comprehensive profile of the material’s mechanical properties.

When it comes to testing shear strength, specialized fixtures and setups are utilized

. For example, a shear test often employs a specimen that is designed to fail under shear loading, allowing for an accurate measurement of shear strength.Importance in Manufacturing

tensile tester shear strength factories

The significance of shear strength testing in manufacturing cannot be overstated. Many industries—from aerospace to automotive and civil engineering—rely on materials that must endure high shear forces. For instance, bolts, rivets, and welded joints are critical components that often experience shear stresses in real-world applications. Failing to assess the shear strength of these components can lead to catastrophic failures and safety hazards.

By using tensile testers, manufacturers can ensure that their materials meet specific standards and performance requirements. Quality assurance processes utilize tensile testing data to not only confirm material properties but also to identify potential weaknesses before production. This proactive approach minimizes the risk of failure in finished products and helps uphold brand reputation.

Advances in Testing Technology

With advancements in technology, tensile testers have become increasingly sophisticated, allowing for more precise measurements and improved efficiencies. Modern tensile testers are equipped with advanced software that can analyze and interpret data in real-time. This capability not only speeds up the testing process but also enhances accuracy, enabling manufacturers to make informed decisions swiftly.

Moreover, with the growing demand for high-performance materials, stress testing has evolved. Manufacturers are now focusing on composite materials, which can exhibit complex shear properties. Consequently, the development of customized testing methods and innovative fixtures is essential to accurately assess the shear strength of these advanced materials.

Conclusion

In conclusion, the integration of tensile testers in assessing shear strength is an indispensable aspect of manufacturing. By understanding and measuring both tensile and shear strengths, industries can ensure the reliability and safety of their products. As technology continues to advance, so too will the methods by which we assess and understand material properties. Manufacturers who prioritize rigorous testing are not only protecting their investments but also contributing to the broader goal of enhancing product quality and safety in various applications. Whether in aerospace, automotive, or construction, the implications of shear strength testing are profound, underscoring its critical role in contemporary manufacturing practices.

-

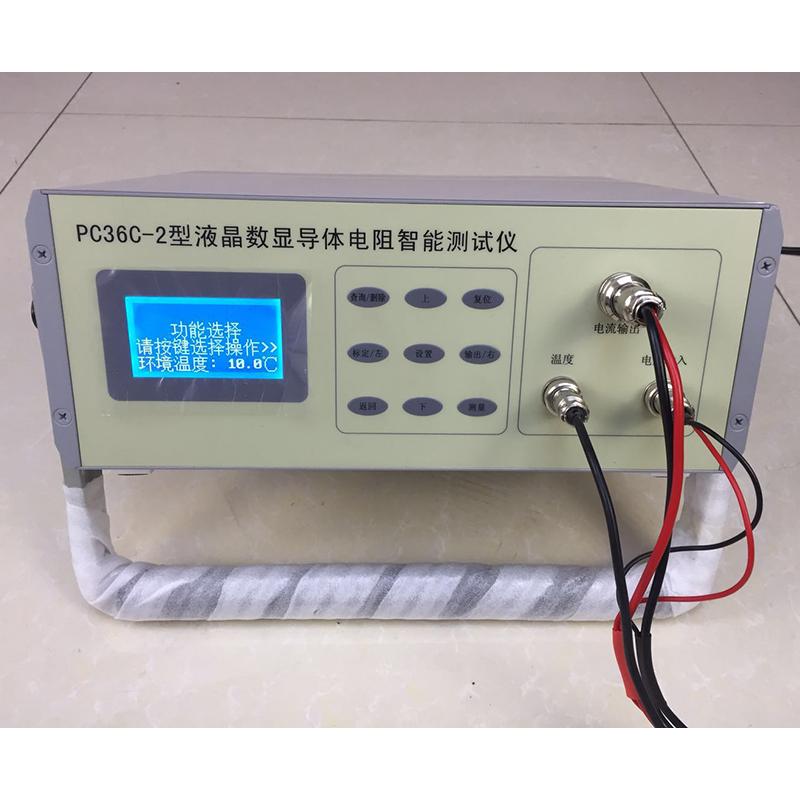

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy