tensile tester shear strength suppliers

Understanding Shear Strength and Its Testers A Guide to Suppliers

When it comes to material testing, understanding shear strength is fundamental in various engineering fields, particularly for ensuring the integrity and safety of materials used in construction, manufacturing, and product design. Shear strength refers to the maximum shear stress a material can withstand before failure occurs. It is a crucial property for materials that are subjected to forces that can cause them to slide past one another. To accurately measure shear strength, various testing methods and equipment are employed, and the choice of testing equipment is essential for obtaining reliable data.

One of the most common methods used to determine shear strength is through the use of a tensile tester, also known as a universal testing machine (UTM). This machine not only measures tensile strength but can also be configured for shear testing, making it versatile for various applications. The tensile tester typically consists of a frame that holds the test specimen and is equipped with a load cell to measure the force applied to the specimen. The data collected from these tests is critical for engineers and manufacturers to ensure that the materials meet specified requirements and standards.

There are numerous suppliers of tensile testers globally, providing a wide array of options for businesses and institutions in need of reliable testing equipment

. When selecting a supplier for tensile testers with shear strength capabilities, several factors should be considered.1. Quality of Equipment The quality of the tensile tester is paramount. A reliable supplier must offer tested and certificated equipment capable of delivering consistent and accurate results. Equipment should comply with international standards such as ASTM, ISO, or EN to ensure that the obtained data is universally accepted.

2. Range of Materials Different applications require testing for various materials, including metals, plastics, composites, and ceramics. A good supplier will provide equipment that can handle a wide range of materials and test sizes. This flexibility ensures that businesses can cover all their testing needs under one roof.

tensile tester shear strength suppliers

3. Customization Options Every industry has specific testing requirements. Suppliers that offer customizable testing solutions—such as different grips, fixtures, and configurations—can cater to unique client demands, enhancing the testing process for specific materials or geometries.

4. Technical Support and Training Quality suppliers should not only provide equipment but also offer ongoing support, maintenance, and training for their products. This service is crucial for ensuring that testing personnel can efficiently operate the machinery and interpret the results correctly.

5. Price and Warranty Price is always a significant consideration. Suppliers should offer competitive pricing without compromising on quality. Additionally, a good warranty period is paramount as it provides security for the investment made by the purchaser.

6. Reputation and Reviews Lastly, it is essential to consider the supplier’s reputation in the marketplace. A supplier with positive customer reviews and a solid track record of reliability and service will provide peace of mind when purchasing such critical equipment.

In conclusion, shear strength testing is an essential process in material science and engineering, and selecting the right tensile tester supplier can significantly impact testing outcomes. By focusing on quality, material range, customization options, technical support, price, and supplier reputation, businesses can ensure they invest in the best equipment for their needs. This, in turn, will help maintain high standards of safety and reliability in their applications, ultimately contributing to the success and durability of their products in the market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

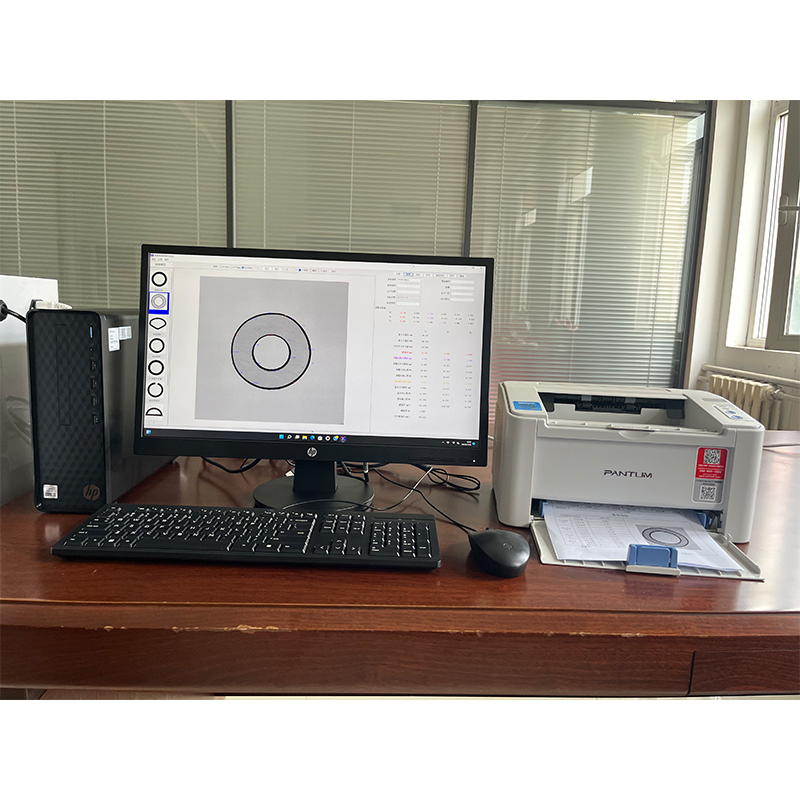

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy