tensile testing machine company

Understanding the Importance of Tensile Testing Machines in Material Strength Assessment

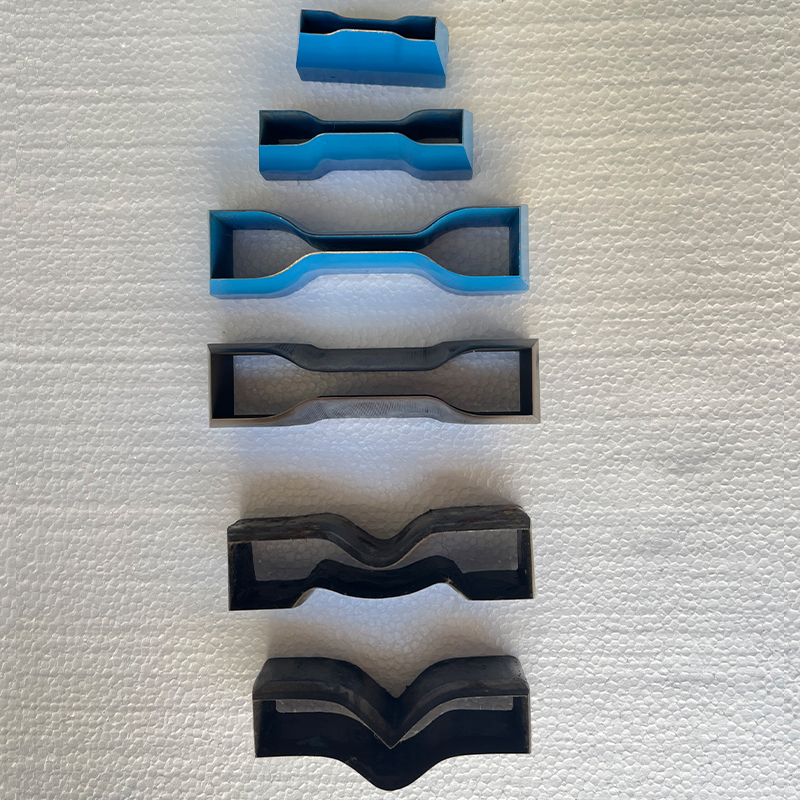

Tensile testing machines play a crucial role in evaluating the strength and durability of materials used in various industries. These sophisticated devices are designed to apply controlled tension to a sample material, allowing engineers and researchers to determine its tensile properties. The insights gained from tensile testing are essential for ensuring product safety, performance, and reliability.

Understanding the Importance of Tensile Testing Machines in Material Strength Assessment

One of the leading companies in the tensile testing machine market is Instron, known for its commitment to innovation and quality. Instron’s machines are built to accommodate a wide range of materials, including metals, polymers, textiles, and composites. The company uses advanced technology and software that enables seamless integration with testing protocols, ensuring accurate and reliable results. By providing detailed testing feedback, Instron’s machines help engineers make informed decisions about material selection and processing.

tensile testing machine company

Another noteworthy company in this field is ZwickRoell, which offers a diverse range of tensile testing solutions tailored to various industries. Their machines are equipped with features like automated testing processes, real-time data analysis, and intuitive user interfaces. These capabilities significantly enhance productivity and efficiency in laboratories, allowing for higher throughput without compromising quality. ZwickRoell’s commitment to customer service also sets them apart, providing robust support and training to ensure users maximize the benefits of their equipment.

As industries evolve, the demand for precise material characterization continues to grow. Modern tensile testing machines are increasingly becoming automated, integrating digital technologies and data analytics. This transformation allows for the collection of vast amounts of data that can be processed and analyzed to gain deeper insights into material behavior. Additionally, advancements in machine learning and artificial intelligence are paving the way for predictive analytics in material science, helping companies forecast material performance under various conditions.

The importance of tensile testing cannot be overstated; it is essential for meeting regulatory standards and certifications. Industries are required to conduct rigorous testing to comply with safety regulations set by governing bodies. Tensile testing helps companies mitigate risks associated with material failure, ultimately safeguarding both human life and investments.

In conclusion, tensile testing machines represent a vital component in the assurance of material performance and safety across multiple industries. Companies like Instron and ZwickRoell lead the charge in providing innovative testing solutions that empower manufacturers and researchers alike. The future of tensile testing lies in further integration of technology and automation, ensuring that materials can be tested more efficiently, accurately, and comprehensively than ever before. As we continue to push the boundaries of materials engineering, the role of tensile testing will remain indispensable.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy