Suppliers of Tensile Testing Equipment for Material Strength Analysis and Quality Assurance

Choosing the Right Tensile Test Machine Supplier A Comprehensive Guide

In the realm of material science and engineering, the testing and characterization of materials are crucial aspects of ensuring product quality and performance. One of the essential tests conducted in this domain is the tensile test, which measures how materials behave under tension. Consequently, selecting a reliable tensile test machine supplier is critical for industries ranging from construction to automotive and aerospace. This article discusses the factors to consider when choosing a tensile test machine supplier and highlights the importance of selecting the right one.

Understanding the Tensile Test

Before delving into supplier selection, it is essential to understand what a tensile test entails. This test involves subjecting a material specimen to a controlled tension until failure, measuring parameters such as elongation, yield strength, and ultimate tensile strength. A well-executed tensile test provides vital information about a material's mechanical properties, helping engineers make informed decisions about material selection, design standards, and safety.

Key Factors in Selecting a Tensile Test Machine Supplier

When choosing a supplier for tensile test machines, several factors come into play

1. Quality and Compliance Standards The performance and reliability of tensile test machines are paramount. Suppliers should provide equipment that adheres to international testing standards, such as ASTM and ISO. Look for certifications that attest to quality assurance, as these validate the machinery's performance and safety.

2. Range of Equipment Different applications require different types of tensile testing machines, including universal testing machines (UTMs), micro and macro tensile testers, and specialized machines for specific materials. A good supplier should offer a diverse range of equipment to cater to various testing requirements.

tensile test machine suppliers

3. Customization Options Since each industry has unique testing needs, a supplier should be willing to offer custom solutions. Whether it involves specific grips, fixtures, or software, the ability to tailor machines to meet your requirements is a significant advantage.

4. Technical Support and Services Exceptional customer service and technical support are critical for ongoing operations. Choose a supplier that provides not only installation and training but also comprehensive after-sales support, including maintenance services, calibration, and troubleshooting assistance.

5. Competitive Pricing While high-quality equipment typically comes at a premium, it is important to find a supplier who offers transparent pricing without hidden costs. Consider the total cost of ownership, including service agreements and warranties, to ensure long-term value.

6. Reputation and Experience Evaluate the supplier's track record and experience in the industry. A reputable supplier is likely to have numerous satisfied customers and can provide case studies or testimonials. Research online reviews and seek recommendations from industry peers for insights into their experiences.

7. Technological Advancements As technology evolves, so do testing methods and machines. A forward-thinking supplier should keep up with the latest innovations, such as digital control systems, advanced data acquisition software, and automation capabilities. Investing in modern technology ensures that you remain competitive in your field.

Conclusion

The selection of a tensile test machine supplier is a decision that can significantly impact your operations, from testing accuracy to production efficiency. By considering factors such as quality, range of equipment, customization, technical support, pricing, reputation, and technological advancements, you will be better equipped to make an informed choice.

In conclusion, never underestimate the importance of thorough research and due diligence when choosing a supplier. A quality tensile test machine, backed by superior customer service and technological support, can greatly assist in yielding accurate and reliable data, contributing to the overall success of your projects. By investing time and effort in the selection process, you will lay the groundwork for enhanced material testing capabilities and ultimately drive innovation in your field.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

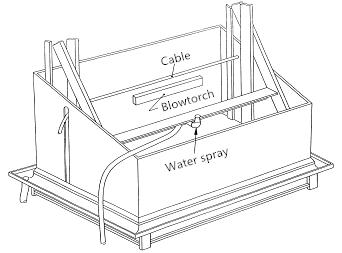

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy