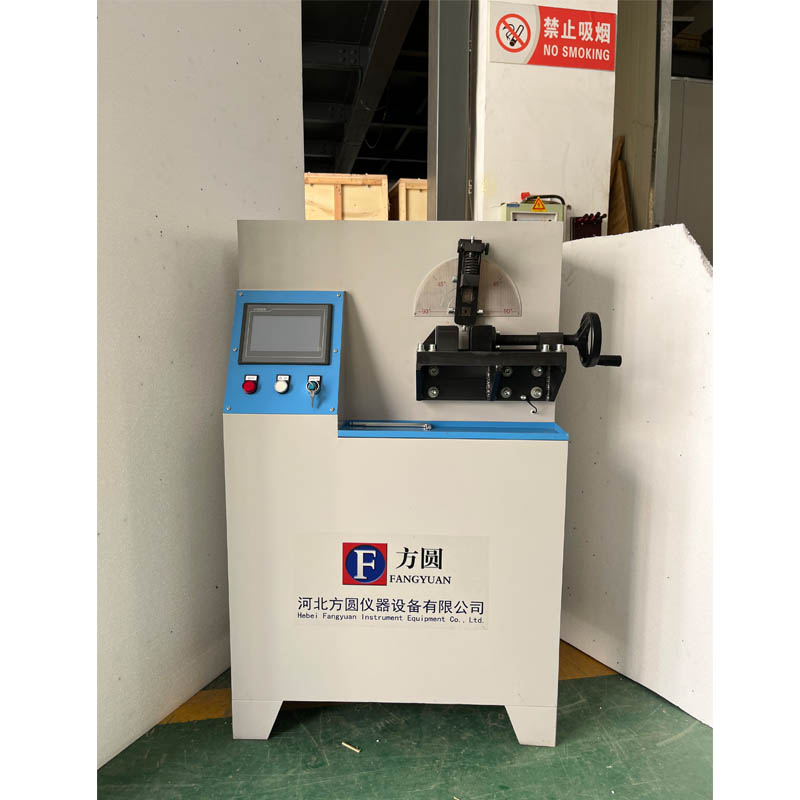

tensile tests machine exporter

The Role of Tensile Test Machines in Material Quality Assurance

In today's manufacturing landscape, the integrity of materials used in production processes cannot be overstated. The performance and reliability of a product are heavily dependent on the quality of the materials that constitute it. Among various testing methodologies, tensile testing stands out as a vital process that provides critical data on the mechanical properties of materials. The demand for tensile test machines has surged, leading to the rise of numerous exporters who play a pivotal role in supplying these essential tools to industries worldwide.

Understanding Tensile Testing

Tensile testing is a type of mechanical test in which a sample material is subjected to a controlled tension until failure. This method measures several key properties, including ultimate tensile strength, yield strength, elongation, and reduction in area. These attributes are crucial for determining how materials behave under stress and are vital for engineers and designers in various sectors, including construction, automotive, aerospace, and manufacturing.

The tensile test involves preparing a standardized specimen, often shaped like a dog bone, which is then placed in a tensile test machine. The machine exerts a continuous pull on the specimen at a specific speed until it fractures. The data collected during this process not only helps in understanding the material's behavior but also ensures compliance with international standards, offering assurance to both manufacturers and consumers.

The Importance of Tensile Test Machines

Tensile test machines are indispensable instruments in quality assurance processes for any enterprise that relies on strong, reliable materials. These machines provide quantitative data that influence product design, processing, and safety standards. By conducting tensile tests, manufacturers can ensure that the materials used in their products can withstand the various loads and stresses they encounter during use. This is particularly critical in industries like aerospace, where a failure of materials can have catastrophic consequences.

Moreover, tensile tests help in identifying any flaws in the manufacturing process. If a material does not meet the required standards, it may indicate issues in the production line or with raw materials. Thus, tensile test machines serve not only as testing devices but also as a means of continuous improvement in manufacturing processes.

tensile tests machine exporter

The Growing Market for Exporters

As global standards for material quality become more stringent, the market for tensile test machines has expanded significantly. Exporters of these machines cater to a diverse array of industries across various countries, ensuring that manufacturers have access to reliable testing equipment. These exporters are often responsible for providing not only the machines themselves but also the necessary support, including installation, maintenance, and training on how to effectively use the machines.

The competitive landscape of tensile test machine exporters is influenced by several factors. Quality, precision, and the range of features offered by the machines play a crucial role in differentiating one exporter's products from another's. Modern tensile testing machines come equipped with advanced technology, including computer control, data acquisition systems, and advanced software that facilitate accurate testing and analysis. Thus, exporters that can offer machines with superior features and reliability tend to gain a larger share of the market.

Challenges in Exporting Tensile Test Machines

Despite the overall growth in demand, exporters face several challenges in this industry. Compliance with international quality standards is paramount, and any discrepancies can lead to significant losses and penalties. Additionally, exporters need to navigate the complexities of international trade regulations, including tariffs and shipping logistics, which can impact their ability to deliver on time.

Another challenge lies in the rapid technological advancements in tensile test machine design. Exporters must stay updated with the latest innovations to ensure that their offerings remain competitive. This requires a commitment to research and development, which may not be feasible for all exporters.

Conclusion

Tensile test machines play a crucial role in ensuring the quality and reliability of materials used in various industries. As the demand for high-quality materials continues to rise, the market for tensile test machine exporters is poised for growth. By overcoming the challenges associated with international trade and technological advancements, these exporters can continue to provide manufacturers with the tools they need to maintain and enhance product quality. In doing so, they contribute significantly to safety, efficiency, and innovation across multiple sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy