Tensile Strength Tester for Accurate Yield Measurement and Material Performance Analysis

Understanding the Tensile Yield Tester A Vital Tool in Material Testing

In the realm of material science and engineering, ensuring the integrity and reliability of materials is paramount. Among the plethora of testing devices available, the tensile yield tester stands out as an essential tool for assessing the mechanical properties of materials, particularly metals and polymers. This article delves into the functionality, importance, and applications of the tensile yield tester in modern material evaluation.

What is a Tensile Yield Tester?

A tensile yield tester, often referred to as a tensile testing machine, is designed to measure the tensile strength, yield strength, elongation, and other related properties of a material under axial loading. The basic principle involves applying a continuous axial load to a sample until it deforms or fractures. The data obtained from this testing not only informs the material selection process but also aids in quality control, ensuring that the materials meet the required specifications for various applications.

Key Components of the Tester

Typically, a tensile yield tester consists of a loading mechanism (such as a hydraulic or servo-controlled system), a test specimen holder, and a data acquisition system. The test specimen is usually shaped into a standardized form, such as a dog-bone shape, to ensure uniform stress distribution during testing. The loading mechanism applies a tensile force, while the data acquisition system captures the material's response, allowing for an analysis of the stress-strain curve.

Importance of Tensile Testing

Tensile testing is crucial for several reasons

1. Material Selection Engineers and designers rely on tensile yield testers to gather data on the mechanical properties of materials. The results help in selecting the right materials for specific applications, ensuring safety and durability.

tensile yield tester

2. Quality Control Industries that manufacture materials or components utilize tensile testing as part of their quality control processes. By verifying materials against standardized specifications, companies can prevent failures in service, which could lead to safety hazards.

3. Research and Development In research and development, understanding how materials behave under tensile loads depends on accurate testing. Continuous innovations in materials, especially in composite and lightweight materials, necessitate rigorous testing to push the boundaries of performance.

4. Regulatory Compliance Many industries, especially aerospace, automotive, and construction, are governed by strict regulations. Tensile yield testing provides the documentation required to comply with these standards, demonstrating that materials can withstand expected loads.

Applications of Tensile Yield Testing

The applications of tensile yield testing span diverse industries. In the automotive sector, it helps determine the strength and ductility of metals used in vehicle components. In the aerospace industry, tensile testing ensures that materials used in aircraft structures can handle extreme conditions without failing.

Additionally, tensile yield testers are vital in civil engineering for testing construction materials like steel and concrete, as well as in the manufacturing of textiles and plastics. As technology advances, new materials, such as graphene and bio-based composites, are emerging, necessitating the ongoing relevance of tensile testing in development and application.

Conclusion

In summary, the tensile yield tester plays a pivotal role in material testing across various industries. By providing critical data on the mechanical properties of materials, it facilitates informed decision-making in material selection, enhances product quality, supports compliance with safety standards, and drives innovation. As materials continue to evolve, the importance of tensile yield testing will only grow, solidifying its status as a cornerstone of modern engineering practices.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

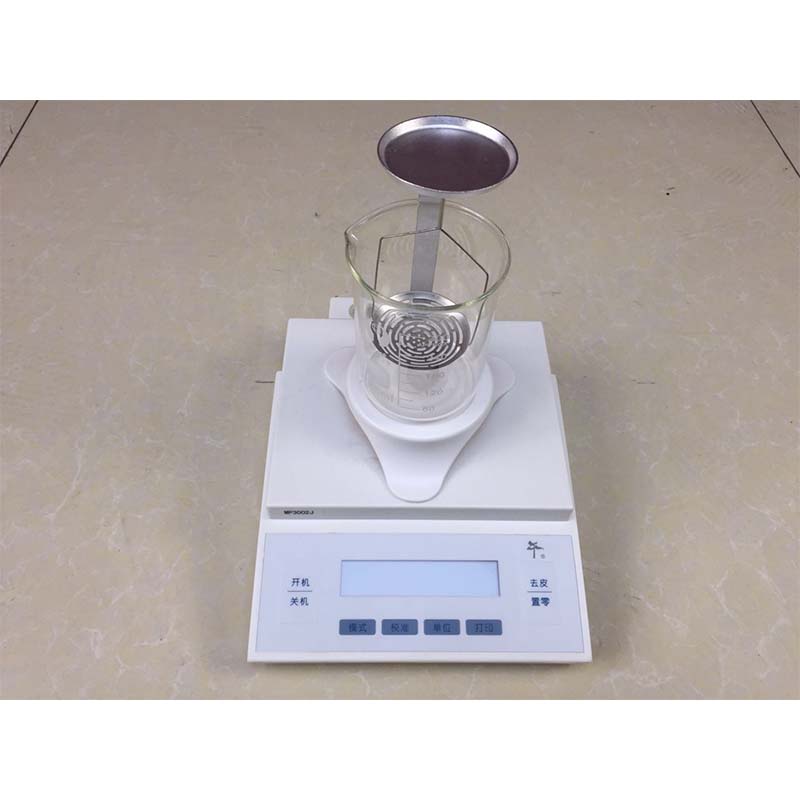

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy