Tensile Strength Tester Manufacturer for Precision Material Testing Solutions

The Role of Tensile Yield Tester Exporters in Enhancing Material Testing Standards

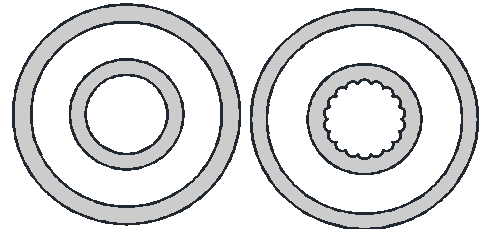

In the world of materials science and engineering, the tensile yield tester plays a pivotal role in evaluating the properties of various materials. This device measures the force required to stretch or compress a material until it reaches its yield point, providing essential data for engineers and manufacturers. As global demand for high-quality materials intensifies, the role of tensile yield tester exporters becomes increasingly significant in ensuring that industries have access to reliable and efficient testing equipment.

Tensile yield testers are used across multiple industries, including construction, automotive, aerospace, and manufacturing. These testers not only help determine the tensile strength of materials but also assess other critical properties such as elongation, modulus of elasticity, and reduction of area. By providing accurate and reproducible results, these devices enable companies to adhere to material specifications and regulatory standards, thus ensuring product safety and reliability.

Exporters of tensile yield testers play a crucial role in the global supply chain by bridging the gap between innovative manufacturers and end-users who require advanced testing equipment. They source state-of-the-art technology from manufacturers in regions known for their engineering expertise, such as the United States, Germany, and Japan. These exporters not only supply equipment but also offer valuable services, including installation, maintenance, and training, ensuring that clients can maximize the utility of the technology.

tensile yield tester exporter

One of the key factors driving the demand for tensile yield testers in international markets is the increasing emphasis on research and development (R&D) in various sectors. As companies strive to innovate and create superior products, rigorous testing becomes essential. Tensile yield testers are integral in the R&D phase, enabling engineers to explore material behaviors under different conditions and develop new alloys and composites tailored to specific applications.

Moreover, the rise of e-commerce and digital marketplaces has transformed how tensile yield tester exporters conduct business. They can now reach a global clientele with ease, allowing smaller manufacturers and startups to access high-quality testing equipment. This democratization of technology has led to a more competitive landscape, pushing manufacturers to enhance their product offerings.

However, the export of tensile yield testers is not without challenges. Exporters must navigate a complex web of regulations and standards in different countries, ensuring that their products comply with local requirements. Additionally, they need to stay abreast of technological advancements to offer the latest and most effective testing solutions to their clients.

In conclusion, tensile yield tester exporters play an indispensable role in the material testing industry. By providing access to high-quality testing equipment and related services, they support manufacturers in achieving compliance with safety standards and enhancing product quality. As industries continue to evolve and prioritize R&D, the demand for reliable tensile yield testers will only grow, making the role of exporters even more critical. Through their efforts, they help ensure that companies worldwide can deliver innovative and safe products, contributing to advancements across various sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy