Tensile Strength Tester Solutions from Leading Manufacturer for Accurate Material Testing

The Importance of Tensile Yield Tester Manufacturers

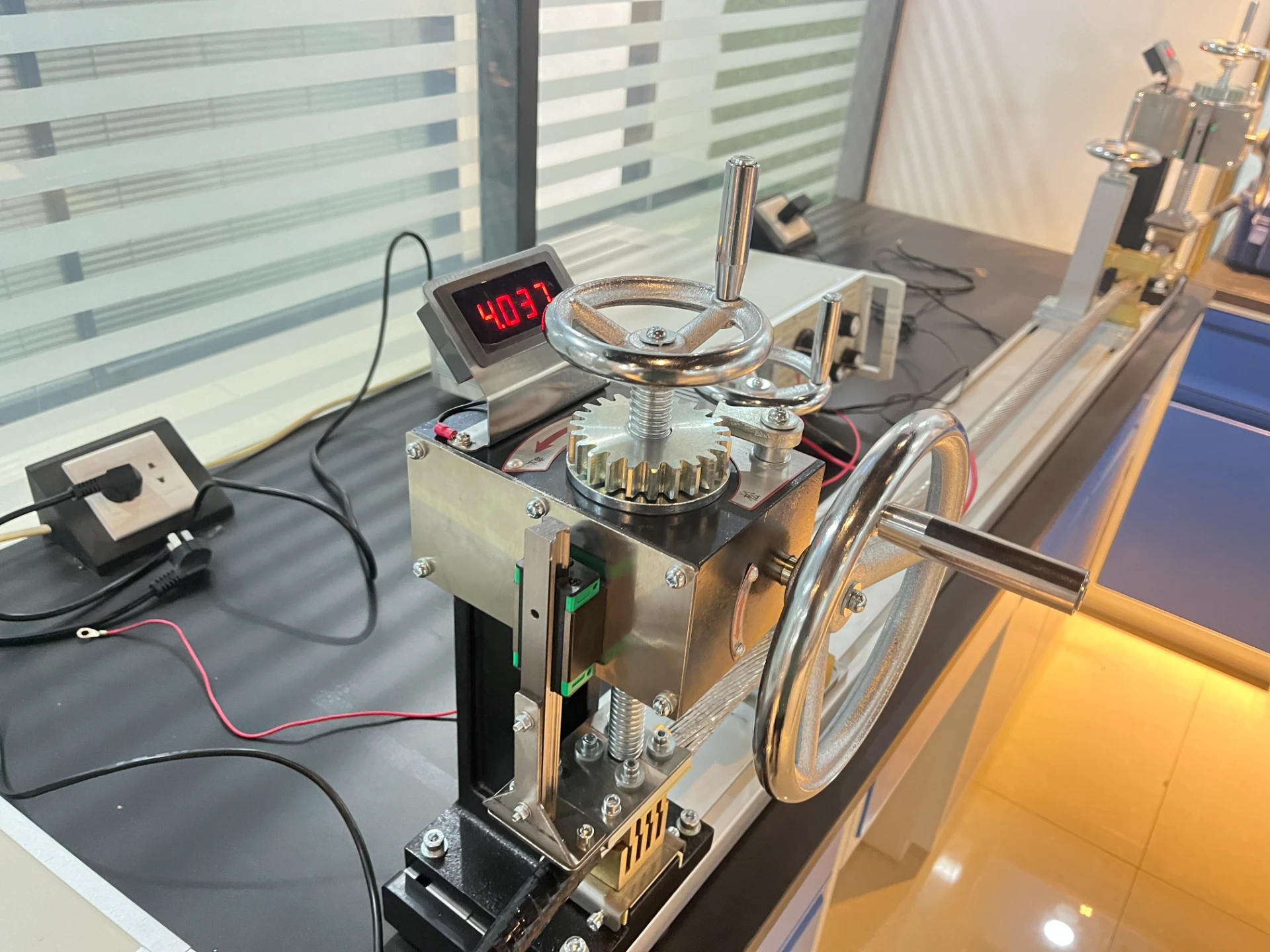

In the realm of material testing, the role of tensile yield testers is paramount. These devices are essential for evaluating the mechanical properties of materials, specifically their strength, ductility, and elasticity. Tensile yield testers provide critical insights that inform the manufacturing processes across various industries, including construction, automotive, aerospace, and consumer goods. The importance of high-quality tensile yield tester manufacturers cannot be overstated.

Tensile yield testers operate by applying a controlled tensile force to a sample until it deforms or breaks. The results yield valuable data, such as the yield strength, ultimate tensile strength, elongation, and reduction of area – all crucial metrics for engineers and product designers. As a result, having reliable and precise equipment is vital for ensuring that materials meet safety and quality standards.

When selecting a manufacturer for tensile yield testers, several factors come into play. Firstly, quality assurance is crucial. A reputable manufacturer will adhere to international standards such as ASTM, ISO, and other relevant guidelines to ensure accuracy and reliability. Advanced materials and innovative technology must be employed in constructing these testers to withstand rigorous testing environments.

Furthermore, customer support and service are significant considerations. A good manufacturer will offer comprehensive support, including installation, calibration, and ongoing maintenance. This relationship is vital for organizations that rely on continuous testing to minimize downtime and ensure compliance with regulatory requirements.

tensile yield tester manufacturer

Customization is another key aspect. Different industries may require specific testing configurations to accommodate varying material types and testing protocols. A proficient manufacturer should be flexible and capable of providing tailored solutions that meet the unique needs of diverse clients.

In addition to functionality, the user interface and data reporting capabilities of tensile yield testers are increasingly important in today's digitized world. Manufacturers that integrate sophisticated software solutions can enhance user experience, allowing for easy data collection, analysis, and reporting. Such features enable engineers to make informed decisions based on timely and accurate data.

Lastly, sustainability is becoming an essential consideration in manufacturing processes. Many organizations are looking for environmentally friendly testing solutions, prompting manufacturers to innovate and adopt greener practices.

In conclusion, the role of tensile yield tester manufacturers is crucial in the material testing landscape. By providing high-quality, reliable, and innovative testing solutions, these manufacturers empower industries to ensure that their products meet necessary safety and quality standards. As industries continue to evolve, the demand for advanced and customized tensile yield testers will likely grow, making it imperative for manufacturers to stay at the forefront of technology and customer service.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy