thermal stability tester supplier

The Role of Thermal Stability Testers in Modern Industries

Thermal stability testing is an essential process utilized across various industries to ensure the reliability and safety of materials and products under extreme temperature conditions. With the rise of new materials and technologies, the demand for accurate and efficient thermal stability testers has soared, leading to the emergence of specialized suppliers in the market. This article delves into the importance of thermal stability testers, their applications, and what to consider when choosing a supplier.

Understanding Thermal Stability Testing

Thermal stability testing involves assessing how materials respond to increasing temperatures. This testing is crucial for materials that will be exposed to varying temperature conditions, such as polymers, metals, and chemical compounds. The tests help determine the degradation point of a material, its melting point, and its potential for yielding harmful byproducts when heated. Industries as diverse as automotive, pharmaceuticals, and electronics rely on these tests to guarantee the safety and longevity of their products.

One of the most common methods of thermal stability testing is Differential Scanning Calorimetry (DSC), which measures how a material’s heat flow changes as temperature varies. Another popular method is Thermogravimetric Analysis (TGA), which evaluates the change in weight of a sample as it is heated, cooled, or held at constant temperature. Both methods provide crucial insight into a material's thermal behavior, allowing engineers and manufacturers to make informed decisions about material selection and product design.

Applications of Thermal Stability Testers

The applications of thermal stability testers are vast and cover a range of industries

1. Plastics and Polymers In the plastics industry, thermal stability testing is critical to ensure that materials can withstand processing temperatures without degrading. This is particularly important for products like pipes, containers, and automotive parts where structural integrity is vital.

2. Pharmaceuticals For the pharmaceutical industry, thermal stability testing is crucial in determining the shelf life of medications. Active ingredients can decompose at elevated temperatures, potentially leading to reduced efficacy. Testing ensures that products remain stable throughout their intended lifespan.

3. Electronics As electronic devices become more compact and powerful, the heat generated during operation is a significant concern. Thermal stability testing helps ensure that components can endure high temperatures without failure, thus maintaining performance and reliability.

thermal stability tester supplier

4. Aerospace In aerospace applications, materials need to perform consistently under extreme thermal stresses. Testing helps in selecting materials that can survive the harsh environments of space travel, such as extreme temperatures and variations in atmospheric pressure.

Choosing a Supplier for Thermal Stability Testers

When selecting a thermal stability tester supplier, several factors should be taken into consideration to ensure you receive the best equipment for your needs

1. Quality and Certification It is essential to choose a supplier that offers high-quality equipment that adheres to international testing standards. Look for suppliers that have ISO certifications or relevant industry acknowledgments.

2. Technology and Features Different testing methods come with various technological advancements. Suppliers should offer a range of options that incorporate the latest innovations, such as automated testing processes, advanced data analysis tools, and user-friendly interfaces.

3. Technical Support and Training A reliable supplier should not only provide equipment but also offer ongoing technical support and training for your staff. Comprehensive training on how to properly use the equipment and interpret the results can greatly enhance the efficiency of your testing protocol.

4. Reputation and Experience Investigate the supplier's reputation in the industry. Companies with a long-standing presence and positive customer feedback are more likely to provide trustworthy products and services.

5. Cost-effectiveness While investment in high-quality thermal stability testers is crucial, it is also essential to consider the cost-effectiveness of the equipment. Compare prices and evaluate what is included, such as software, calibration, and warranty services.

Conclusion

As industries continue to evolve, the need for reliable thermal stability testing becomes ever more critical. By selecting a reputable supplier of thermal stability testers, organizations can ensure the safety, reliability, and quality of their products in challenging thermal environments. The right thermal stability testing equipment not only aids in compliance with regulatory requirements but also enhances product performance, ultimately leading to customer satisfaction and trust in the brand.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

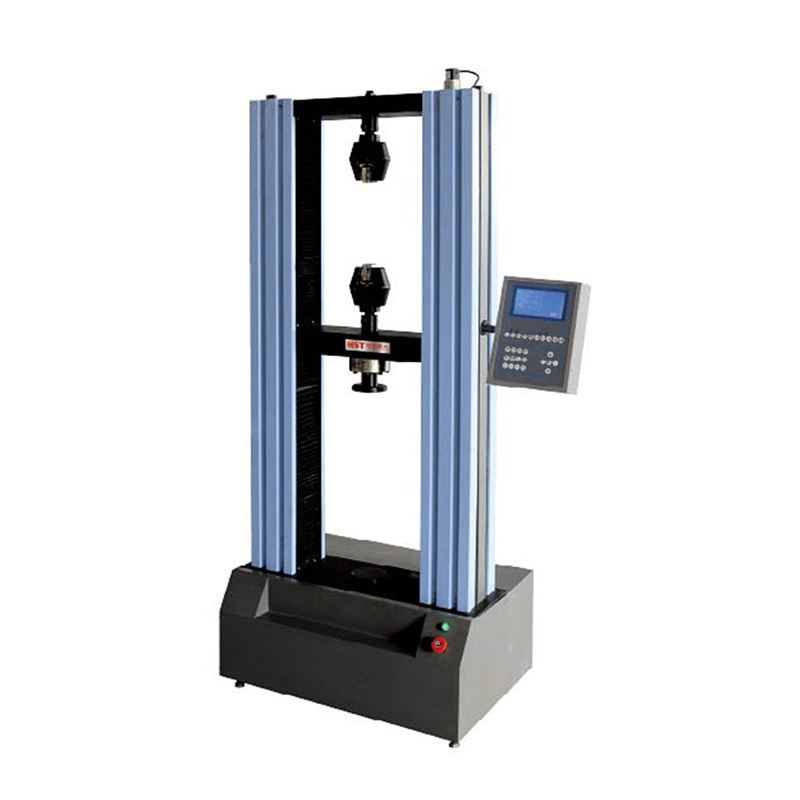

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy