Coaxial Cable Cutting Solutions for Efficient Underground Installations and Repairs

The Evolution of Underground Coaxial Cable Slicers A Key Innovation for Telecommunications

In an age where reliable communication is paramount, the infrastructure that supports our telecommunications systems plays a critical role. Among these infrastructures, underground coaxial cables are vital for transmitting data, television signals, and internet connectivity. To ensure these cables are installed and maintained efficiently, the emergence of specialized tools has been nothing short of transformative. One such tool is the underground coaxial cable slicer, a device that has revolutionized how professionals handle coaxial cables.

The Need for Precision in Cable Installation

As telecommunications networks expand and evolve, technicians are often tasked with installing and repairing underground coaxial cables in a variety of challenging environments. This work requires a meticulous approach, with precision being essential to avoid damaging the cables that carry crucial signals. Traditional methods of cutting cables not only posed risks to the integrity of the cables but also often resulted in inconsistent lengths that could complicate connections.

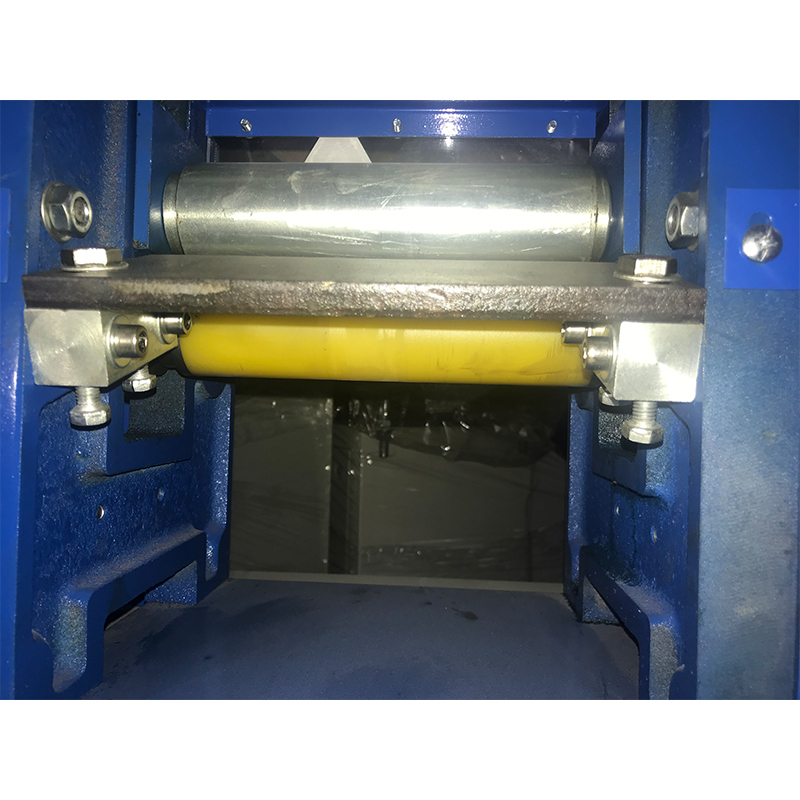

Introducing the Underground Coaxial Cable Slicer

Enter the underground coaxial cable slicer, a tool designed to address these challenges directly. This innovative equipment allows technicians to make clean, precise cuts to coaxial cables without exposing inner wires or risking damage to shielding layers. By incorporating features like adjustable cutting depths and ergonomically designed handles, these slicers enable workers to perform tasks more efficiently while minimizing occupational hazards such as repetitive strain injuries.

Key Features and Benefits

A typical underground coaxial cable slicer boasts several key features that set it apart from traditional cutting tools. Firstly, it incorporates advanced blade technology, made from high-quality materials to ensure durability and sharpness. This feature allows for smooth cuts, reducing the likelihood of fraying or damaging the cable during the slicing process.

underground coaxial cable slicer company

Moreover, many models are equipped with a built-in depth gauge. This ensures that technicians can make a precise cut without worrying about going too deep, which could compromise the cable's structure. The ergonomic design of these tools also plays a vital role in user comfort, allowing for prolonged use without causing fatigue.

Safety Considerations

Safety is a paramount concern in the telecommunications industry, particularly when working underground. The design of underground coaxial cable slicers often includes safety features such as blade guards and locking mechanisms that prevent accidents. Moreover, the use of these specialized slicers reduces the need for manual cutting, which can be both dangerous and inefficient.

Impact on the Telecommunications Industry

The introduction of underground coaxial cable slicers has not only improved cutting precision and safety, but it has also significantly sped up the installation and maintenance processes. Time saved on each job translates into substantial cost savings for companies operating in the telecommunications sector. Faster installations lead to quicker service deployments, which ultimately enhance customer satisfaction.

Looking Ahead The Future of Cable Handling Tools

As technology continues to advance, we can expect further innovations in cable handling tools, including the underground coaxial cable slicer. Potential developments may incorporate digital technologies, such as smart sensors that provide real-time feedback to operators about cable conditions, or enhanced automation to streamline the cutting process even further.

In conclusion, the role of underground coaxial cable slicers cannot be overstated in the context of modern telecommunications. As networks continue to grow, the tools that support their maintenance and installation must evolve to meet new demands. The underground coaxial cable slicer stands as a testament to how innovation can drive efficiency and safety in an industry that is central to our connected lives. For companies operating in this field, investing in high-quality, specialized tools is no longer just an option—it's a necessity for maintaining competitive advantage in a rapidly changing technological landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy