Manufacturer of Underground Coaxial Cable Cutting Tools for Efficient Installation and Maintenance

The Importance of Underground Coaxial Cable Slicers and Their Manufacturers

In the rapidly evolving telecommunications industry, the need for reliable and efficient tools is paramount. One such essential tool is the underground coaxial cable slicer. This specialized equipment is crucial for technicians working with coaxial cables that lie beneath the surface, providing seamless communication services across cities and rural areas alike. Understanding the role of manufacturers in providing high-quality underground coaxial cable slicers is essential to ensure the integrity of our communication networks.

The Functionality of Underground Coaxial Cable Slicers

Underground coaxial cable slicers are designed to cut and expose coaxial cables that are often buried underground. These cables are commonly used in telecommunications, cable television, and internet services, making them vital for modern connectivity. The ability to perform precise cuts and strip cables without damaging the internal components is crucial for maintenance and repair work.

These slicers typically feature ergonomic designs, allowing technicians to work efficiently in challenging underground conditions. Many models include adjustable blades to accommodate various cable sizes, ensuring versatility in different projects. Depending on the manufacturer, some slicers are equipped with additional features such as safety locks to prevent accidents, and built-in measuring tools to enhance accuracy.

The Role of Manufacturers

The manufacturers of underground coaxial cable slicers play a critical role in the telecommunications ecosystem. A reputable manufacturer invests significant resources into research and development to create innovative and reliable products. Advanced manufacturing techniques and high-quality materials are essential in producing tools that withstand rigorous use in the field.

Moreover, the manufacturer’s ability to adapt to industry changes, such as the increasing size and complexity of coaxial cables, is essential. As technology advances, so do the specifications and requirements of underground cables. Manufacturers must ensure that their products meet current standards, and are capable of handling the various types of cables used in today's infrastructure.

underground coaxial cable slicer manufacturer

Quality Assurance and Standards

Quality assurance is another important aspect of the manufacturing process. A dependable underground coaxial cable slicer must undergo rigorous testing to guarantee its effectiveness and durability. This includes testing the blades for sharpness and longevity, the handles for grip and comfort, and the overall construction for resistance to wear and tear.

Manufacturers often adhere to international standards and certifications to validate their products. These standards serve as benchmarks for quality and safety, providing assurance to technicians that the tools they use are reliable. Companies that prioritize compliance with these standards tend to gain market trust and build long-term relationships with their clients.

The Future of Underground Coaxial Cable Slicers

As the telecommunications landscape continues to evolve, the demand for high-quality underground coaxial cable slicers will only increase. With the push towards more advanced communication technologies including 5G and fiber optics, manufacturers must stay ahead of the curve by incorporating new technologies into their products.

Furthermore, the integration of smart technology into these tools could revolutionize the way maintenance is conducted. For example, slicers could be equipped with sensors that provide real-time feedback regarding cable status or alert technicians to potential issues before they escalate.

Conclusion

In summary, underground coaxial cable slicers are indispensable tools that enable the smooth operation of telecommunications networks. The manufacturers behind these products are vital in ensuring that technicians have access to reliable, innovative, and high-quality equipment. As the telecommunications industry moves forward, the collaboration between manufacturers and tech professionals will be crucial in maintaining and enhancing our communication infrastructure. The focus on quality, innovation, and adaptability will pave the way for a more connected world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

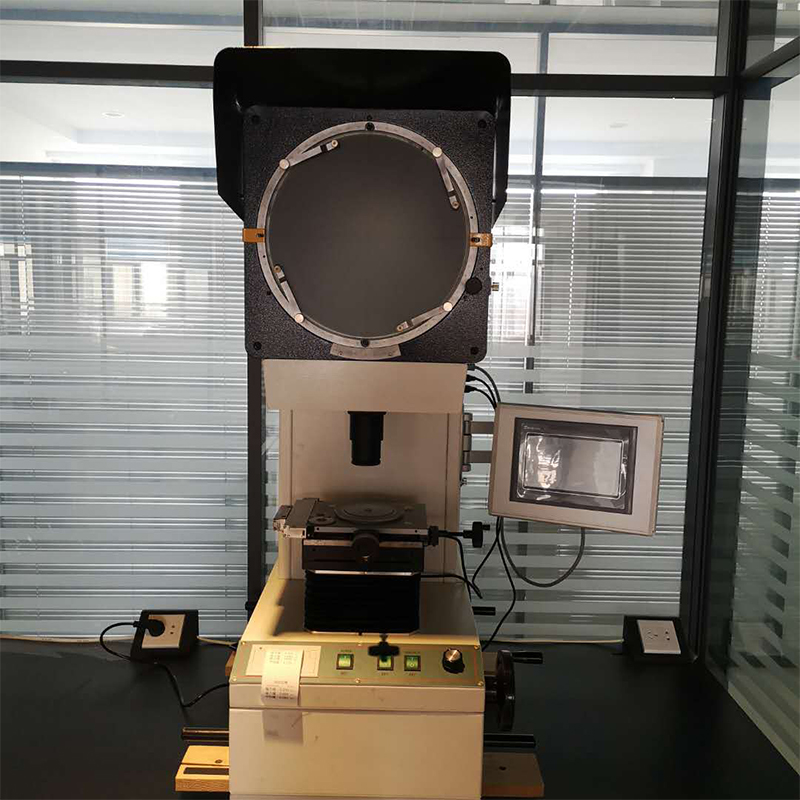

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy