Versatile Tensile Testing Machine for Material Strength Evaluation and Performance Analysis

Understanding the Universal Tensile Tester A Comprehensive Overview

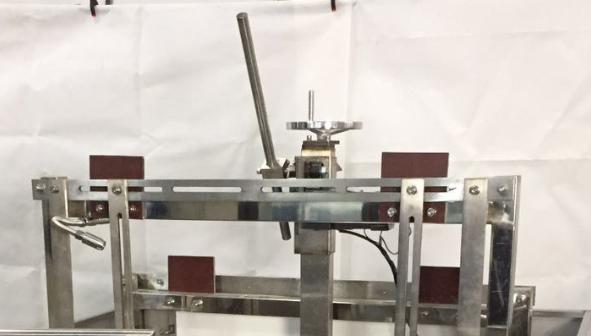

The universal tensile tester is an essential instrument used in materials testing laboratories to evaluate the mechanical properties of various materials, including metals, plastics, and composites. This device plays a pivotal role in determining how materials behave under tensile stress, allowing engineers and researchers to assess the integrity and performance of materials in real-world applications.

What is a Universal Tensile Tester?

A universal tensile tester is a versatile machine designed to measure the tensile strength, yield strength, elongation, and other mechanical properties of a material. It operates by applying a controlled force to a sample specimen until it fractures, providing crucial data on how materials deform and fail under stress. The design of the tensile tester accommodates various specimen shapes and sizes, making it suitable for testing everything from thin films to thick metal plates.

Components of a Universal Tensile Tester

The typical structure of a universal tensile tester includes several key components

1. Load Frame The frame provides the primary support for the apparatus and houses the measurement system. It is often designed to withstand heavy loads and maintain stability during tests.

2. Grips or Fixtures These components hold the specimen securely in place. Different types of grips are used depending on the material being tested, such as wedge grips for metals or pneumatic grips for softer materials.

3. Load Cell This crucial component measures the force applied to the specimen. Load cells convert the mechanical force into an electrical signal, which can be recorded and analyzed.

4. Crosshead The crosshead moves at a controlled speed, pulling the specimen apart. This movement is often programmable, allowing for varying rates of loading depending on the test requirements.

5. Data Acquisition System Integrated with software, this system collects and analyzes data through sensors. It provides real-time feedback and generates graphs depicting the stress-strain curve of the material.

The Testing Process

The testing process typically follows these steps

universal tensile tester

1. Specimen Preparation The material sample is prepared to specific dimensions and shapes according to standardized testing protocols (e.g., ASTM, ISO).

2. Mounting the Specimen The prepared specimen is securely mounted in the grips of the tensile tester.

3. Setting Parameters The operator sets the parameters of the test, including the loading speed and maximum load.

4. Conducting the Test The test begins as the crosshead moves, applying tensile force to the specimen. The machine continuously records the load and elongation data.

5. Data Analysis Upon reaching the breaking point, the test concludes. The data collected is analyzed to generate a stress-strain curve, allowing the determination of various mechanical properties.

Applications of Universal Tensile Testers

Universal tensile testers are widely used across multiple industries

- Aerospace Testing materials for aircraft components to ensure they can withstand high stress and extreme conditions. - Automotive Evaluating materials used in vehicle manufacturing to improve safety and performance. - Construction Assessing the strength and durability of materials like concrete and steel used in buildings and infrastructure. - Research and Development Helping in the development of new materials by analyzing their mechanical properties.

Importance of Tensile Testing

The data obtained from tensile testing is critical for engineers and designers. Understanding material properties helps in making informed decisions about material selection and design, ensuring reliability and safety in applications. By predicting how materials will behave under various load conditions, manufacturers can avoid catastrophic failures and optimize performance.

Conclusion

The universal tensile tester is a vital tool in materials testing that provides essential insights into the mechanical behavior of a wide range of materials. Its ability to accurately measure properties such as tensile strength and elongation plays a crucial role in numerous industries, from aerospace to automotive. As technology advances, the capabilities of universal tensile testers continue to evolve, leading to improved material performance and enhanced safety in engineering designs. Understanding and utilizing this equipment is key to ensuring reliability in modern applications where material integrity is paramount.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy