Universal Tensile Testing Machines Manufacturers for High Precision Material Testing Solutions

Understanding Universal Tensile Testers A Comprehensive Overview

In the realm of material testing, universal tensile testers play a crucial role in determining the mechanical properties of materials. These machines are designed to apply tension to a specimen until failure, enabling engineers and researchers to assess the strength, ductility, and other key characteristics of materials. As industries evolve and the demand for reliable materials increases, understanding the importance of tensile testing and the role of universal tensile tester factories becomes paramount.

What are Universal Tensile Testers?

Universal tensile testers are versatile machines used to conduct tensile tests on various materials, including metals, plastics, rubber, and composites. They measure how materials behave under tension and can provide valuable data regarding yield strength, ultimate tensile strength, elongation, and reduction in area. The design of these testers allows for adjustments in speed, load, and displacement, making them adaptable for different materials and testing standards.

Key Components of a Universal Tensile Tester

A universal tensile tester consists of several essential components

1. Load Frame The load frame is the backbone of the tester, providing structural stability and support during testing. It can be either hydraulic or electromechanical, with the latter offering precise control over the testing process.

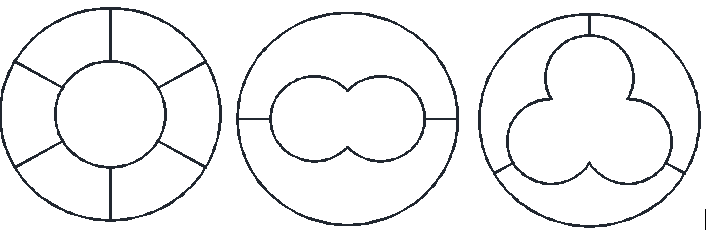

2. Grips The grips hold the test specimen securely in place. Different grip types are available, including wedge grips, pneumatic grips, and hydraulic grips, catering to various material forms and sizes.

3. Load Cell The load cell is a transducer that measures the force applied to the specimen. It converts mechanical force into an electrical signal, which is then processed to provide accurate readings.

4. Extensometer An extensometer measures the elongation of the specimen as the test progresses. It can be attached directly to the specimen or operate in a non-contact mode, depending on the application.

universal tensile tester factories

5. Control System Modern testers feature advanced computer systems that control the testing process, collect data, and facilitate analysis. Many systems come with software that can generate detailed reports and graphs, making it easier to interpret results.

The Role of Universal Tensile Tester Factories

With the rising demand for high-quality materials and the need for rigorous testing, universal tensile tester factories have become vital. These factories specialize in designing and manufacturing tensile testing machines, adhering to international standards such as ASTM, ISO, and JIS.

1. Research and Development Factories invest in R&D to innovate and improve their products. This ensures that their testers incorporate the latest technology, providing more accurate and efficient testing solutions.

2. Customization Different industries may require specific testing capabilities. Universal tensile tester factories often offer customization options to meet unique client needs, whether that involves special grip designs, load capacities, or software functions.

3. Quality Assurance Factories maintain strict quality control measures throughout the manufacturing process. Each machine is thoroughly tested before leaving the facility to ensure reliability and performance.

4. Support and Service Reputable factories provide ongoing support and maintenance services, helping customers troubleshoot issues and keep their machines running optimally. This support is crucial as it extends the lifespan of the equipment.

Conclusion

Universal tensile testers are indispensable tools for evaluating the mechanical properties of materials. As industries continue to demand reliable and high-quality products, the role of universal tensile tester factories becomes increasingly significant. Through innovation, customization, and unwavering quality standards, these factories contribute not only to the accuracy of testing but also to the advancement of material science. By understanding the impact of these machines and their manufacturers, businesses can better appreciate the value of rigorous material testing in ensuring product safety and integrity.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy