Universal Tensile Testing Equipment for Material Strength Evaluation and Analysis

Understanding the Universal Tensile Tester Machine An Essential Tool in Material Testing

The universal tensile tester machine, also known as a universal testing machine (UTM), is a vital instrument in the field of materials engineering and quality control. It is designed to perform a variety of mechanical testing procedures, most notably tensile tests, which are essential for determining the strength, ductility, and elasticity of materials. This machine plays a crucial role in ensuring that materials meet the required specifications for various applications, from construction to manufacturing.

What is a Universal Tensile Tester Machine?

At its core, a universal tensile tester machine consists of a load frame, a test specimen holder, and measuring instruments. The load frame is designed to apply a controlled force to a specimen, which is typically made of metals, plastics, textiles, or composites, until it deforms or fractures. The machine measures the amount of force applied and the corresponding elongation of the material, allowing for the calculation of essential properties such as tensile strength, yield strength, and elongation at break.

The Testing Process

The testing process begins with the sample preparation, where the material specimen is cut into a standardized shape and size. This is crucial for ensuring accurate and reproducible results. The specimen is then securely placed in the grips of the tester. Once the specimen is in position, the machine applies a tensile force by separating the grips at a constant rate. As the material is subjected to increasing stress, the machine continuously records data on the force and extension.

Data from the test is displayed in real-time and can be analyzed to generate stress-strain curves. These curves graphically represent the relationship between stress (force per unit area) and strain (deformation relative to original length). From these curves, various mechanical properties can be derived, such as the modulus of elasticity, which indicates a material's stiffness, and the ultimate tensile strength, which determines how much load a material can withstand before failing.

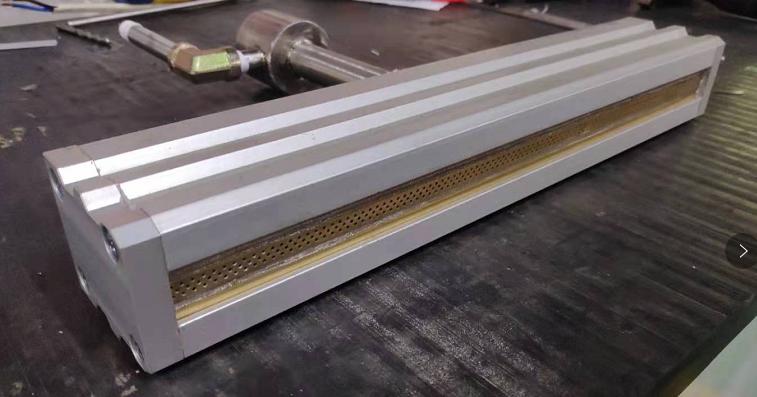

universal tensile tester machine

Applications

Universal tensile tester machines are utilized across various industries, including aerospace, automotive, construction, and textiles. In the automotive industry, for example, materials are tested for their ability to withstand the stresses experienced during operation. The aerospace sector evaluates materials for strength and weight efficiency, crucial for flight safety and performance. In construction, materials such as steel and concrete are routinely tested to ensure they meet safety and structural integrity standards.

Advantages of Universal Testing Machines

One of the major advantages of universal tensile testers is their versatility. Modern UTMs can conduct a wide range of tests beyond tensile testing, including compression, bending, and shear tests, making them indispensable in laboratories. Additionally, advancements in technology have led to the development of computer software that allows for enhanced data analysis, enabling engineers to simulate material behavior under various conditions.

Another significant advantage is the ability to perform tests in accordance with international standards, such as ASTM, ISO, and DIN, ensuring that results are recognized worldwide. This standardization is essential for companies that export products, as compliance with global standards can be a prerequisite for market entry.

Conclusion

The universal tensile tester machine is a cornerstone of material testing that ensures the reliability and quality of materials used in an array of industries. By providing crucial data on material properties, it helps engineers and scientists innovate and improve material usage for enhanced performance and safety. As technology advances, the capabilities of these machines will only continue to grow, further solidifying their role in modern materials science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy