universal tensile tester machine factories

The Importance of Universal Tensile Tester Machines in Manufacturing

In the realm of material testing, universal tensile tester machines play a crucial role in ensuring that materials meet specific quality and safety standards. These machines, often utilized in factories around the world, provide invaluable data regarding the strength, ductility, and overall integrity of materials. As industries continue to evolve, the demand for precise testing equipment has never been more significant.

Universal tensile testers are designed to apply a uniaxial tensile force to a material sample, measuring its response to strain until failure occurs. This testing method is essential for various materials including metals, plastics, textiles, and composites. The data extracted from these tests is critical for quality control, product development, and compliance with industry standards.

Manufacturers rely on universal tensile tester machines for several reasons. Firstly, they assure that the materials used in production are capable of withstanding the stresses they will encounter in real-world applications. For instance, in the automotive industry, the safety of components such as seat belts, frames, and engine parts hinges on their ability to handle tensile forces without failure. A failure in these components can lead to catastrophic results, emphasizing the need for rigorous testing.

Moreover, the data obtained from universal tensile testing can aid in the selection of materials. Engineers can analyze stress-strain curves to determine which materials will best suit a specific application. This ensures not only the safety and efficacy of the product but also optimizes manufacturing costs by eliminating unsuitable materials early in the design phase.

universal tensile tester machine factories

In factories, the integration of advanced digital universal tensile testing machines has revolutionized the way manufacturers conduct tests. Equipped with software that can analyze data in real-time, these machines offer high precision and reliability. Results can be stored and compared, facilitating a comprehensive understanding of material properties over time. Such digital solutions enhance automation in factories, allowing companies to streamline their testing processes and boost productivity.

Furthermore, universal tensile testers contribute significantly to research and development (R&D) within manufacturing. Companies invest in R&D to innovate and improve products continuously. By utilizing tensile testing machines, engineers can experiment with new materials or combinations, refining their properties for specific applications. This iterative process is essential for fostering innovation and maintaining a competitive edge in the market.

As environmental concerns mount, universal tensile testers also play a role in sustainability efforts. By ensuring that materials used are both strong and lightweight, manufacturers can develop products that consume less energy during production and usage. Lightweight materials, for instance, lead to more fuel-efficient vehicles, aligning with global sustainability goals.

In conclusion, universal tensile tester machines are indispensable in modern manufacturing environments. Their role in quality assurance, material selection, and R&D cannot be overstated. As technology advances, we can expect even more sophisticated testing machines to emerge, driving improvements in safety, efficiency, and sustainability. As industries adapt to the challenges of the future, the reliance on precise and reliable testing methods will undoubtedly grow, solidifying the place of universal tensile testers in the manufacturing landscape.

-

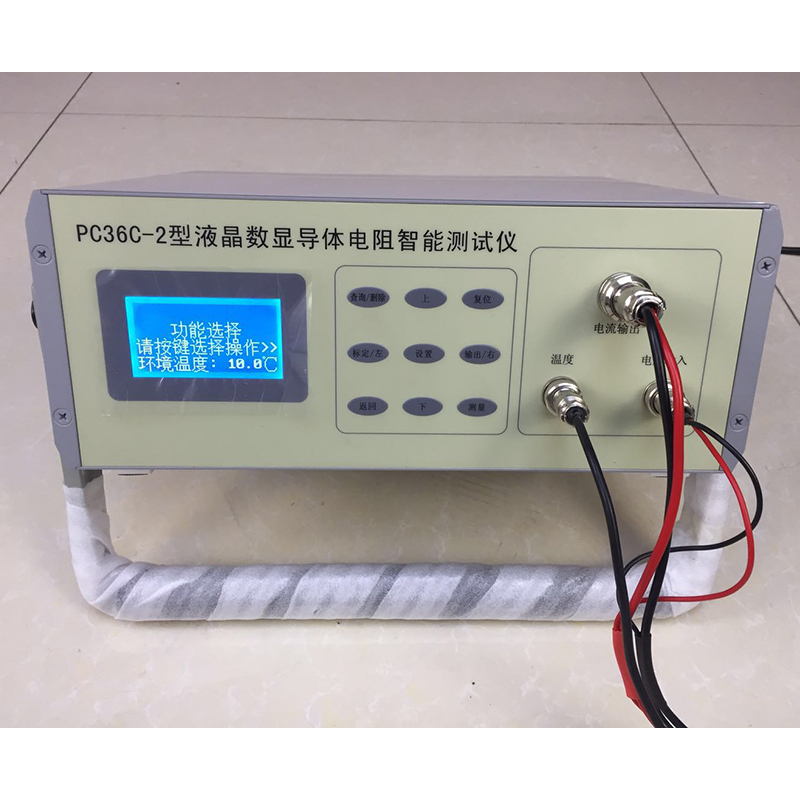

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy