universal tensile tester machine factories

Understanding Universal Tensile Tester Machines An Overview of Their Factories

In the realm of material testing, universal tensile tester machines play a pivotal role. These machines are designed to measure the tensile strength, compression, and other mechanical properties of materials such as metals, plastics, rubber, and composites. They are widely utilized in various industries, including construction, aerospace, automotive, and manufacturing. This article will delve into the factories producing these sophisticated machines, exploring their processes, technologies, and the significance of their contributions to material science.

What is a Universal Tensile Tester Machine?

A universal tensile tester, also known as a universal testing machine (UTM), is an essential tool in laboratories and production lines. It operates by applying a controlled force to a material specimen until it deforms or fractures. The machine measures parameters such as elongation, yield strength, ultimate tensile strength, and modulus of elasticity.

The test results are critical for quality assurance, research and development, and compliance with industry standards. Given the wide-ranging applications of these machines, their design, manufacturing, and calibration are of utmost importance to ensure accuracy and reliability.

Factories Producing Universal Tensile Tester Machines

The production of universal tensile tester machines occurs in specialized factories that focus on combining engineering prowess with cutting-edge technology

. These facilities are equipped with advanced machinery and tools to handle precision fabrication and assembly processes.universal tensile tester machine factories

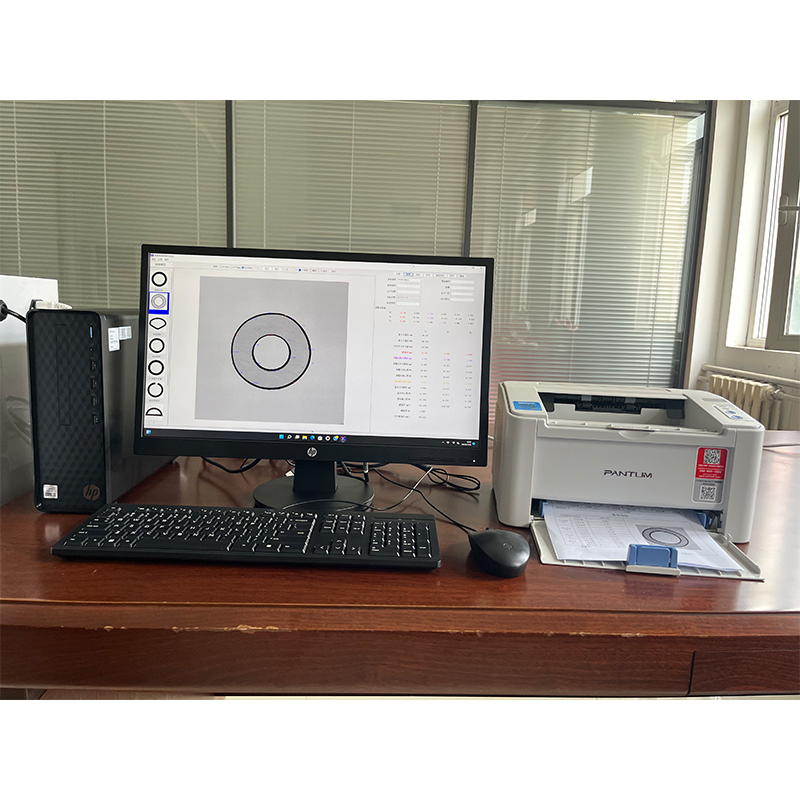

1. Research and Development Renowned manufacturers invest heavily in research and development (R&D) to innovate and enhance their UTM models. This includes integrating advanced sensors, automation systems, and data analysis software to improve testing accuracy and ease of use. Factories often have dedicated R&D departments that work collaboratively with engineers and scientists.

2. Precision Manufacturing The factories involved in the production of universal tensile testers utilize state-of-the-art manufacturing techniques. This includes CNC (Computer Numerical Control) machining, laser cutting, and 3D printing to create parts that meet stringent specifications. Quality control is integral to the manufacturing process, with rigorous testing of components to ensure they can withstand high levels of stress and strain.

3. Quality Assurance Quality assurance protocols are vital in the factories producing universal testing machines. These protocols include extensive testing of finished products under various conditions to simulate real-world applications. Manufacturers ensure that their machines comply with international standards such as ISO and ASTM, which govern the performance and safety of testing equipment.

4. Customization and Support To meet the diverse needs of clients across different sectors, many factories offer customization options for their universal tensile testers. This may involve adjusting the machine's capacity, adding specific testing fixtures, or integrating software solutions tailored to particular materials. Furthermore, providing exceptional customer support and training on machine operation is a core aspect of many manufacturers' services.

5. Sustainability Practices Modern factories are increasingly adopting sustainable practices in their operations. This includes using environmentally friendly materials, minimizing waste through efficient processes, and ensuring energy-efficient manufacturing methods. Sustainability is not just a trend but is becoming a crucial factor for manufacturers looking to enhance their market appeal.

Conclusion

Universal tensile tester machines are crucial tools for ensuring the performance and safety of materials used across various industries. The factories responsible for their production are at the heart of this essential process, combining innovative technology with skilled craftsmanship. As demands for accurate material testing continue to grow, these factories will evolve, incorporating advanced technologies and sustainable practices to meet the needs of a rapidly changing world. By investing in these areas, manufacturers not only enhance their product offerings but also contribute to the advancement of material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy