Leading Manufacturer of Universal Tensile Testing Machines for Material Strength Evaluation

Understanding Universal Tensile Tester Machines A Comprehensive Overview

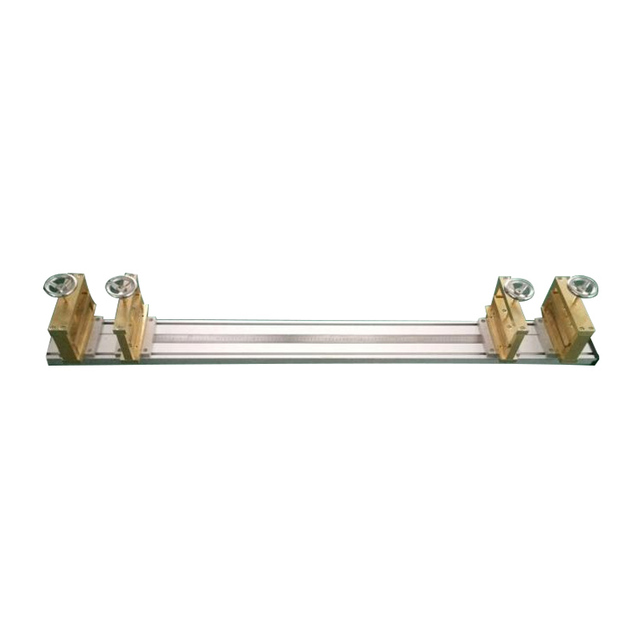

In the realm of material testing, the universal tensile tester machine stands out as a fundamental instrument for evaluating the mechanical properties of various materials. Manufacturers of these machines play a crucial role in various industries, ensuring that products meet the stringent quality and safety standards required in today’s competitive market.

What is a Universal Tensile Tester Machine?

A universal tensile tester machine, also known as a universal testing machine (UTM), is designed to apply tensile and compressive forces to materials in a controlled environment. It measures properties such as tensile strength, elongation, and yield point, providing vital data that informs material selection and product development processes. These machines can test a wide range of materials, including metals, plastics, textiles, and composites, making them indispensable for manufacturers across different sectors.

Key Features of Universal Tensile Tester Machines

1. Versatility Universal tensile testers are equipped to perform a variety of tests beyond tensile strength measurements. They can conduct compression tests, flexural tests, and hardness tests, thus serving multiple purposes and enhancing their value in the testing lab.

2. Precision and Accuracy The accuracy of test results is paramount in material testing. Reputable manufacturers utilize advanced technology and high-quality components to ensure precise measurements. Modern machines often incorporate digital displays, computer interfaces, and data acquisition systems that enhance measurement reliability.

3. User-Friendly Interfaces With advancements in technology, many manufacturers are focusing on making their equipment more accessible. Intuitive software interfaces allow users to set up tests easily, monitor real-time data, and analyze results without needing extensive training.

universal tensile tester machine manufacturer

4. Safety Features Given the potentially hazardous nature of material testing, safety is a critical consideration in the design and manufacturing of universal tensile testers. Safety mechanisms, such as overload protection and emergency stop features, ensure that both the operator and the machine remain secure during operations.

The Role of Manufacturers in Quality Assurance

Manufacturers of universal tensile tester machines are responsible for more than just producing equipment; they provide comprehensive solutions that enhance product quality. Their machines help companies meet regulatory compliance and industry standards, preventing costly failures and recalls. By investing in high-quality testing equipment, manufacturers can improve their production processes, reduce waste, and enhance customer satisfaction through reliable and durable products.

Innovation in Material Testing Technology

The continuous evolution of technology means that manufacturers of universal tensile testers must stay ahead of the curve. Innovations such as enhanced automation, cloud-based data storage, and integration with IoT devices are becoming prevalent. These advancements not only streamline the testing process but also enable real-time data analysis, facilitating quicker decision-making and problem-solving.

Conclusion

Universal tensile tester machines are integral to ensuring the quality and reliability of materials across various industries. As manufacturers continue to enhance their designs and incorporate new technologies, the capabilities of these machines expand, allowing for more sophisticated testing methods. By prioritizing quality and innovation, manufacturers of universal tensile tester machines contribute significantly to the advancement of material science and engineering, ultimately leading to safer and more effective products for consumers. Investing in a reliable universal tensile tester is essential for any organization committed to maintaining high standards in material performance and quality assurance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy