Universal Testing Machine for Tensile Strength Measurement and Material Analysis

Understanding Universal Tensile Testing Machines

A universal tensile testing machine (UTM) is an essential piece of equipment used in materials science to assess the mechanical properties of various materials, including metals, plastics, and composites. This machine plays a crucial role in quality control, research, and development in a multitude of industries. Understanding its functionality, applications, and significance is vital for engineers, material scientists, and technicians alike.

Functionality of Universal Tensile Testing Machines

The primary function of a UTM is to apply a controlled tensile load to a specimen until it fails. This process helps determine key mechanical properties such as tensile strength, elongation, yield strength, and modulus of elasticity. A standard tensile test involves measuring the force applied to the specimen and its corresponding elongation, which is represented in a stress-strain curve. This curve provides vital information regarding how a material behaves under stress, indicating its ductility, toughness, and overall performance in practical applications.

Universal tensile testing machines are equipped with robust grips or fixtures that secure the specimen in place. The machine applies a gradual or constant load, allowing for precise measurements to be taken. Modern UTMs typically feature advanced sensors and software that facilitate real-time data acquisition and analysis, enhancing the accuracy of results. Users can initiate tests with automated settings, and results can be easily exported for further analysis.

Applications in Various Industries

Universal tensile testing machines are widely used across several industries, including aerospace, automotive, construction, and manufacturing. In the aerospace industry, for example, the integrity of materials is paramount due to the extreme conditions encountered during flight. UTMs help identify materials that can withstand high levels of stress and fatigue, ensuring safety and durability.

universal tensile testing machine

In the automotive sector, UTMs are utilized to evaluate components such as chassis materials, which must provide strength and durability while also being lightweight. The results from tensile testing inform engineers about the ability of a material to handle the stresses during operation, helping in the design of safer and more efficient vehicles.

Moreover, the construction industry leverages tensile testing machines to ensure building materials like steel and concrete meet required specifications. Understanding the tensile properties of these materials can lead to more resilient structures capable of withstanding various loads.

Significance of Material Testing

The importance of testing materials with a UTM cannot be overstated. By providing reliable data on mechanical properties, these machines help prevent structural failures and ensure compliance with industry standards and regulations. Furthermore, they aid in the research and development of new materials, allowing scientists and engineers to explore innovative solutions for enhancing material performance.

In the era of advanced manufacturing and material science, the role of universal tensile testing machines is becoming increasingly crucial. As industries strive for greater efficiency and sustainability, understanding the mechanical properties of materials will remain a key factor in driving innovation and ensuring quality.

Conclusion

In conclusion, universal tensile testing machines are indispensable tools in the evaluation of material properties. Their ability to provide accurate and reproducible data on tensile strength and other mechanical attributes helps ensure safety and performance across a variety of applications. As technology continues to advance, the capabilities of UTMs are expected to evolve, offering even more precise insights into material behavior and enhancing the quality of products across numerous industries. Consequently, investing in these machines is a strategic decision for any organization that prioritizes material integrity and product excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

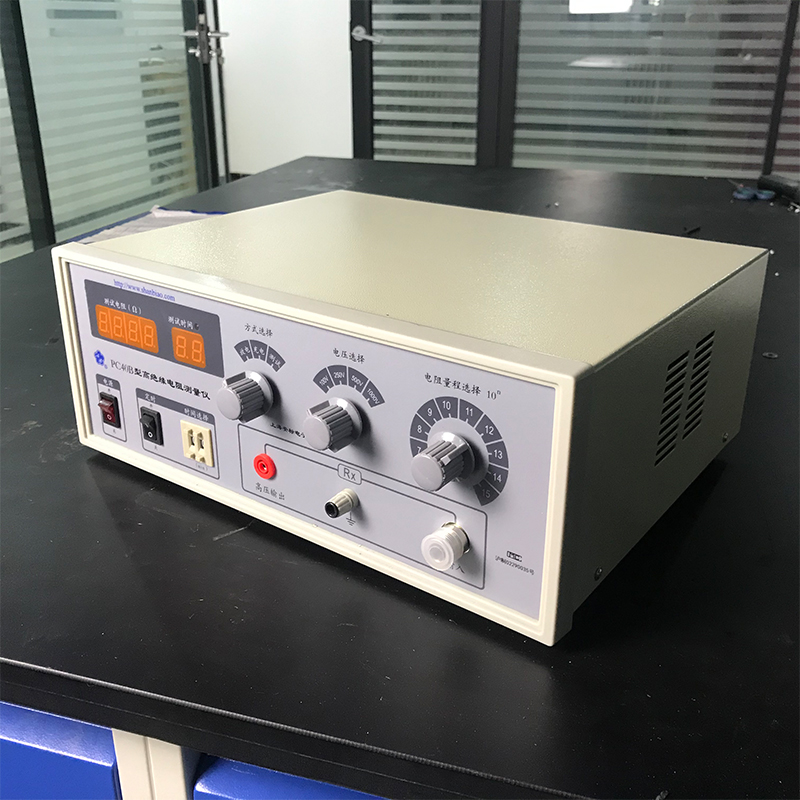

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy