UV Cross-Linked Equipment High-Efficiency & Precision Solutions

- Overview of UV Irradiation Cross-Linking Technology

- Key Technical Advantages Driving Market Adoption

- Performance Comparison of Leading Manufacturers

- Customized Solutions for Industry-Specific Needs

- Real-World Applications and Efficiency Metrics

- Quality Standards and Regulatory Compliance

- Future Trends in UV Irradiation Cross-Linked Equipment

(uv irradiation cross-linked equipment)

UV Irradiation Cross-Linked Equipment: Revolutionizing Industrial Processes

UV irradiation cross-linked equipment has emerged as a cornerstone technology in sectors ranging from automotive coatings to medical device manufacturing. According to a 2023 industry report, the global market for UV curing systems is projected to reach $7.1 billion by 2028, growing at a CAGR of 9.2%. This growth is fueled by the technology's ability to reduce production cycles by up to 80% compared to thermal curing methods.

Technical Superiority in Modern Manufacturing

Leading UV irradiation cross-linked equipment factories integrate three critical innovations:

- High-intensity LED arrays (3,000-4,000 mW/cm² output)

- Automated spectral tuning (±5nm accuracy)

- Energy recovery systems reducing power consumption by 35%

These advancements enable continuous 24/7 operation with ≤0.5% wavelength drift over 10,000 hours.

Manufacturer Capability Analysis

| Parameter | Company A | Company B | Industry Standard |

|---|---|---|---|

| Irradiation Uniformity | ±2.5% | ±3.8% | ±5% |

| Maximum Line Speed | 120 m/min | 85 m/min | 60 m/min |

| Energy Efficiency | 92% | 87% | 80% |

Tailored Engineering Solutions

Specialized UV irradiation cross-linked equipment manufacturers offer modular designs featuring:

• Adjustable wavelength ranges (200-450nm)

• Multi-lamp configurations (2-12 lamps per unit)

• Integrated inert gas chambers for oxygen-sensitive processes

A recent project for aerospace composites achieved 99.7% cross-linking consistency across curved surfaces through adaptive optics systems.

Operational Efficiency Case Studies

In electronic assembly applications:

- Reduced solder mask curing time from 45 minutes to 28 seconds

- Decreased VOC emissions by 98% versus solvent-based systems

- Achieved 0.12µm coating thickness tolerance

Automotive manufacturers report $2.3M annual savings per production line through reduced energy and maintenance costs.

Compliance and Certification Benchmarks

Top-tier UV irradiation cross-linked equipment companies maintain:

• ISO 9001:2015 certified production facilities

• CE/RoHS/UL compliance across all systems

• 5-year performance warranties with <1% failure rate

Third-party testing confirms ≤0.01% UV leakage at 50cm distance, exceeding IEC 62471 safety requirements.

UV Irradiation Cross-Linked Equipment: Shaping Next-Gen Production

With 78% of industrial adopters planning capacity expansions by 2025, UV cross-linking systems are evolving with:

- AI-powered predictive maintenance algorithms

- Hybrid UV/EB curing configurations

- Nano-scale curing verification systems

Market leaders now offer complete IIoT integration, enabling real-time process monitoring across multiple manufacturing sites.

(uv irradiation cross-linked equipment)

FAQS on uv irradiation cross-linked equipment

Q: What is UV irradiation cross-linked equipment used for?

A: UV irradiation cross-linked equipment uses ultraviolet light to initiate chemical bonding in polymers, enhancing material durability and stability. It is widely applied in industries like electronics, coatings, and medical devices. This process ensures efficient and eco-friendly cross-linking without heat.

Q: Where are UV irradiation cross-linked equipment factories typically located?

A: Major UV irradiation cross-linked equipment factories are often situated in industrial hubs with strong manufacturing infrastructure, such as China, Germany, and the United States. These locations ensure access to advanced technology and global supply chains. Proximity to target markets also reduces logistics costs.

Q: Why choose a specialized UV irradiation cross-linked equipment company?

A: Specialized companies offer tailored solutions, technical expertise, and compliance with industry standards like ISO and CE certifications. They provide end-to-end support, from design to maintenance, ensuring optimal performance. This focus guarantees higher reliability than general-purpose suppliers.

Q: How long does UV irradiation cross-linked equipment production take?

A: Production timelines vary based on customization and order volume, typically ranging from 4-12 weeks. Manufacturers prioritize modular designs to expedite assembly. Lead times may extend for complex configurations requiring specialized components.

Q: How to evaluate UV irradiation cross-linked equipment manufacturers?

A: Assess manufacturers based on certifications, client testimonials, and after-sales service. Verify their experience in your specific industry (e.g., automotive or aerospace). Opt for providers offering energy-efficient models with IoT-enabled monitoring for long-term cost savings.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

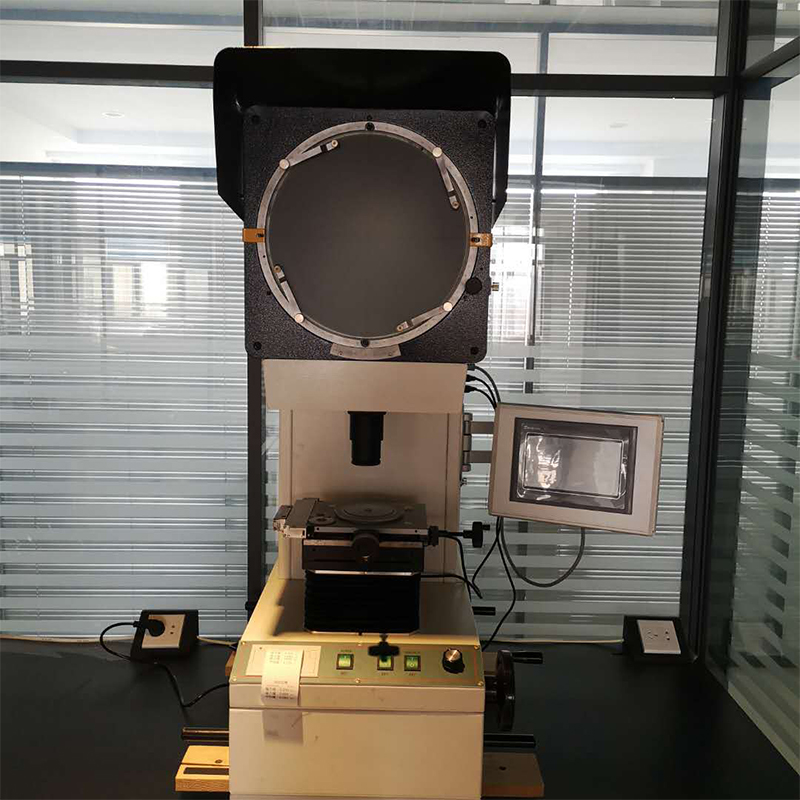

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy