uv irradiation cross-linked machine factories

The Role of UV Irradiation in Cross-Linking Processes in Machine Factories

In the ever-evolving landscape of manufacturing, UV irradiation has emerged as a pivotal method in the cross-linking of materials, significantly enhancing the durability and performance of products. This process is particularly valuable in machine factories, where precision and longevity are paramount.

UV irradiation cross-linking involves the application of ultraviolet light to initiate a chemical reaction in polymers and other materials, leading to the formation of covalent bonds between molecules

. This results in a three-dimensional network that imparts superior mechanical properties, resistance to heat, chemicals, and environmental degradation. In machine factories, these enhanced characteristics translate into longer-lasting components that can withstand harsher operating conditions.One of the most prominent applications of UV cross-linking in machine factories is in the production of coatings and adhesives. UV-cured coatings provide exceptional hardness and chemical resistance, making them ideal for parts that face rigorous wear and tear. For instance, machinery exposed to fluids and varying temperatures benefits immensely from surfaces treated with UV-cured products, which remain intact longer than their traditional counterparts.

uv irradiation cross-linked machine factories

Additionally, UV cross-linking significantly reduces production time compared to conventional curing methods. Traditional processes often require heat and extended periods to fully cure materials. In contrast, UV curing can be completed in a matter of seconds, allowing manufacturers to speed up their production lines and increase overall efficiency. This rapid processing not only optimizes workflow but also conserves energy, aligning with sustainable manufacturing practices.

Safety is another compelling aspect of UV irradiation in machine factories. Compared to other cross-linking methods, such as those involving toxic chemicals or extensive heat application, UV treatment poses a lower risk to workers. Moreover, the lack of volatile organic compounds (VOCs) in UV-cured materials aligns with stringent environmental regulations, making it a more eco-friendly option.

The integration of UV irradiation technology in machine factories also opens doors to innovative material developments. Researchers are constantly exploring its potential in creating advanced composites and smart materials that respond dynamically to their environment. The future of manufacturing lies in these adaptive materials, which can revolutionize how machines operate and interact with their surroundings.

In conclusion, UV irradiation cross-linking represents a transformative approach in machine factories. By enhancing material properties, accelerating production times, ensuring worker safety, and fostering innovation, this technology is not just improving existing processes but also paving the way for a more efficient and sustainable future in manufacturing. As industries continue to embrace this method, the potential for advancements in product quality and operational efficiency remains limitless.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

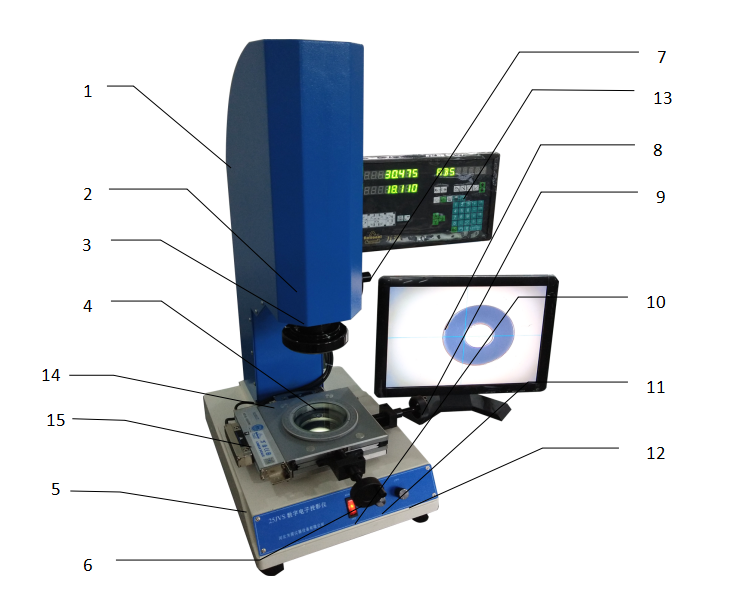

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy