UV Crosslinking Equipment Providers for Superior Polymer Bonding Solutions

The Importance of UV Crosslinking Equipment Suppliers

In today's fast-paced manufacturing and engineering landscape, UV crosslinking technology has become a cornerstone for various industries, including automotive, aerospace, electronics, and medical sectors. As the demand for high-performance materials continues to rise, the need for effective and reliable UV crosslinking equipment cannot be overstated. This article delves into the significance of UV crosslinking equipment suppliers and their pivotal role in enhancing production capabilities and ensuring product quality.

Understanding UV Crosslinking Technology

UV crosslinking is a process that enhances polymer materials by forming chemical bonds in the presence of ultraviolet light. This technology is particularly advantageous for curing coatings, adhesives, and inks, providing rapid curing times and improved mechanical properties. The crosslinked materials exhibit higher durability, chemical resistance, and thermal stability, making them suitable for a wide range of applications.

The Role of UV Crosslinking Equipment Suppliers

UV crosslinking equipment suppliers are essential partners in the manufacturing process, offering a wide array of machines and systems tailored to specific industry needs. These suppliers provide not just the equipment, but also the expertise required for integrating UV crosslinking solutions into existing manufacturing setups. Here are a few key roles they play

1. Providing Innovative Technology Suppliers are at the forefront of technological advancements in UV crosslinking. They continually research and develop new systems that improve efficiency, reduce energy consumption, and enhance the quality of the curing process. Advanced equipment often incorporates features such as adjustable wavelengths, precise intensity controls, and automated systems that allow more consistent and effective curing.

2. Customization and Flexibility Every industry has unique requirements, and a one-size-fits-all approach rarely works. Reputable suppliers offer customizable solutions that can be tailored to specific application needs. This flexibility can include adjusting machine sizes, curing depths, or even the integration of other processing technologies, ensuring that businesses can meet their operational requirements without compromising on quality.

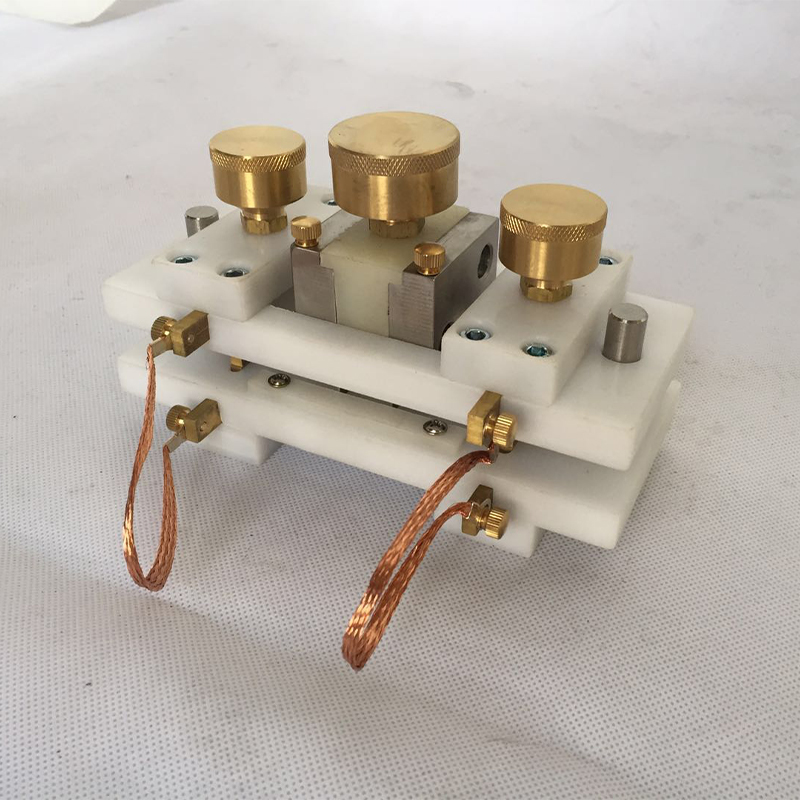

uv crosslinking equipment supplier

3. Technical Support and Expertise Beyond supplying equipment, leading suppliers provide invaluable technical support. This includes guidance on equipment selection, installation, and maintenance, as well as training programs for staff. Suppliers help clients navigate the complexities of UV technology, ensuring they fully understand how to maximize the capabilities of their equipment.

4. Quality Assurance and Compliance As industries face increasing regulatory pressures regarding product safety and environmental impact, suppliers play a vital role in ensuring that equipment meets the necessary standards. By partnering with credible suppliers, businesses can rest assured that they are using compliant technologies that adhere to both local and international regulations.

5. Long-term Partnerships The relationship between manufacturers and equipment suppliers often extends beyond a simple transaction. Suppliers can act as strategic partners, offering ongoing support, updates on the latest technologies, and insights into industry trends. Such partnerships enable businesses to remain competitive and innovative in their offerings.

The Future of UV Crosslinking

As industries continue to evolve and focus on sustainability, the importance of UV crosslinking technology is anticipated to grow. Manufacturers are increasingly seeking eco-friendly processes that minimize waste and emissions, and UV crosslinking stands out due to its ability to cure materials quickly and without the use of solvents. Additionally, with advancements in automation and smart technology, the future of UV crosslinking equipment is set to become even more efficient and interconnected.

Conclusion

In summary, the role of UV crosslinking equipment suppliers is crucial in the modern manufacturing landscape. They not only provide the necessary equipment and technology but also offer support, customization, and expertise to help businesses thrive in a competitive environment. As the demand for high-performance materials continues to rise, partnering with a trusted UV crosslinking equipment supplier will be essential for companies looking to enhance their production capabilities and ensure product quality. By embracing this technology and leveraging the expertise of suppliers, industries can pave the way for innovative and sustainable manufacturing practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy