uv irradiation cross-linked machine companies

The Rise of UV Irradiation Cross-Linking Technologies in Manufacturing

In recent years, the manufacturing sector has experienced significant advancements, particularly in the realm of polymer chemistry and material sciences. One of the standout techniques making waves is UV irradiation cross-linking, a process that enhances the durability and performance of materials used in a variety of applications. This article explores the benefits, applications, and leading companies in the field of UV irradiation cross-linking technology.

What is UV Irradiation Cross-Linking?

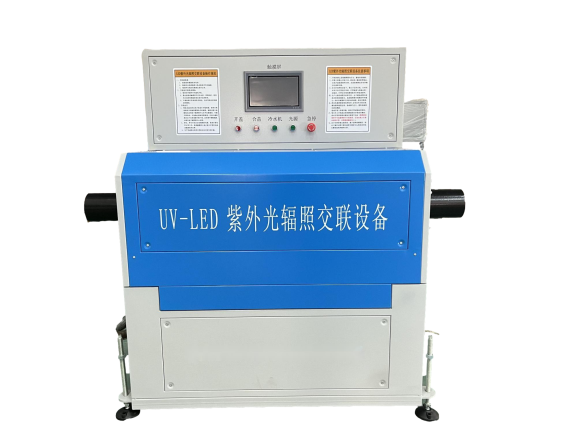

UV irradiation cross-linking is a photochemical process that utilizes ultraviolet (UV) light to initiate a reaction that promotes the formation of cross-links between polymer chains. This results in a three-dimensional network structure, which improves the mechanical and chemical properties of the polymer. The primary advantage of this process is its speed; compared to traditional thermal curing methods, UV irradiation can significantly reduce production times, making it an attractive option for manufacturers.

Benefits of UV Cross-Linking

1. Efficiency and Speed UV cross-linking can cure materials within seconds, drastically reducing the time from production to market. This rapid curing process allows manufacturers to increase their production rates and respond more quickly to market demands.

2. Energy Savings The process requires significantly less energy compared to conventional methods, as it relies on UV light rather than extended heating. This energy efficiency is appealing for companies looking to minimize their environmental footprint and operational costs.

3. Enhanced Material Properties UV cross-linking improves properties such as chemical resistance, thermal stability, and mechanical strength. This makes it ideal for applications in industries such as automotive, electronics, and medical devices.

4. Versatility The technology can be employed with a variety of materials, including inks, coatings, adhesives, and resins, making it highly adaptable to different manufacturing processes.

5. Low Emission Process Unlike some traditional curing processes that emit volatile organic compounds (VOCs), UV cross-linking tends to produce fewer emissions, contributing to a safer working environment and better regulatory compliance.

Applications Across Industries

The advantages of UV irradiation cross-linking have led to its widespread adoption across various sectors

- Automotive Industry UV-cured coatings provide durable finishes that resist scratching and corrosion, leading to enhanced vehicle aesthetics and longevity.

uv irradiation cross-linked machine companies

- Electronics In the production of circuit boards, UV cross-linking improves bonding and insulation properties, crucial for the reliability of electronic devices.

- Medical Devices Sterilizable and biocompatible materials are increasingly being produced using UV cross-linking, ensuring safety and functionality in medical applications.

- Packaging UV-cured inks and adhesives are becoming the norm in the packaging industry, enabling faster production cycles while maintaining high quality and performance standards.

Leading Companies in UV Cross-Linking Technology

The push for advanced UV cross-linking solutions has seen numerous companies entering the market, each contributing to the technology's evolution. Here are some of the notable players

1. Huntsman Corporation A leader in specialty chemicals, Huntsman has leveraged UV cross-linking to develop advanced coatings and adhesives, enhancing their applications in various industries.

2. Dow Chemical Company Known for its innovation, Dow has been at the forefront of developing UV-cured resins that improve performance and reduce environmental impact in manufacturing processes.

3. BASF This global chemical powerhouse offers a range of UV benefits through its diverse portfolio of UV-curable solutions, catering to industries from automotive to consumer goods.

4. Nippon Gohsei Based in Japan, Nippon Gohsei specializes in functional polymers, utilizing UV cross-linking to create products with superior performance characteristics.

5. Henkel With a strong focus on adhesives and sealants, Henkel has integrated UV cross-linking technology into its offerings, creating products that are both efficient and effective.

Conclusion

The evolution of UV irradiation cross-linking technology is reshaping the manufacturing landscape, offering significant advantages in efficiency, energy consumption, and material performance. As industries continue to innovate and seek sustainable solutions, companies embracing this technology are likely to lead the pack in providing high-quality products while minimizing their environmental impact. As the demand for quicker, more efficient manufacturing processes grows, UV cross-linking is positioned to remain a vital component of modern production methodologies.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy