UV Irradiation Cross-Linking in Factory Settings for Enhanced Material Durability and Performance

Innovations in UV Irradiation Cross-Linked Machinery in Modern Factories

In the ever-evolving landscape of manufacturing, the integration of advanced technologies plays a pivotal role in enhancing production efficiency, product quality, and operational sustainability. Among these innovations, UV irradiation cross-linking stands out as a transformative process, particularly in the production of materials that require enhanced durability and resistance to environmental factors. This article explores the significance of UV irradiation cross-linked machinery in modern factories, its applications, benefits, and future prospects.

Understanding UV Irradiation Cross-Linking

UV irradiation cross-linking is a chemical process that involves exposing materials, typically polymers, to ultraviolet light. This exposure initiates a reaction that creates cross-links between polymer chains, thus forming a three-dimensional network. The result is a material that exhibits superior mechanical properties, thermal stability, and chemical resistance compared to its non-cross-linked counterparts. This process finds extensive application in industries such as adhesives, coatings, inks, and medical devices.

The Role of Machinery in UV Irradiation Cross-Linking

The machinery designed for UV irradiation cross-linking has evolved significantly over the years. Modern factories utilize specific equipment that offers precise control over the UV light exposure, ensuring uniform cross-linking across the material. Advanced UV curing systems feature adjustable wavelengths and intensities, enabling manufacturers to tailor the process according to the specific requirements of the material being processed.

Moreover, automation plays a crucial role in these machines. Automated systems streamline the production process, allowing for continuous operation and minimizing human error. This not only speeds up production times but also enhances safety in the workplace, as operators are less exposed to harmful UV radiation. Additionally, advanced monitoring systems integrated into the machinery provide real-time data on curing processes, enabling manufacturers to maintain consistent quality standards.

Benefits of UV Irradiation Cross-Linking Machinery

The advantages of employing UV irradiation cross-linked machinery in factories are manifold. Firstly, the speed of the curing process is significantly faster than traditional methods, which often rely on heat or chemical curing. UV curing can occur in seconds, drastically reducing production times and boosting overall efficiency.

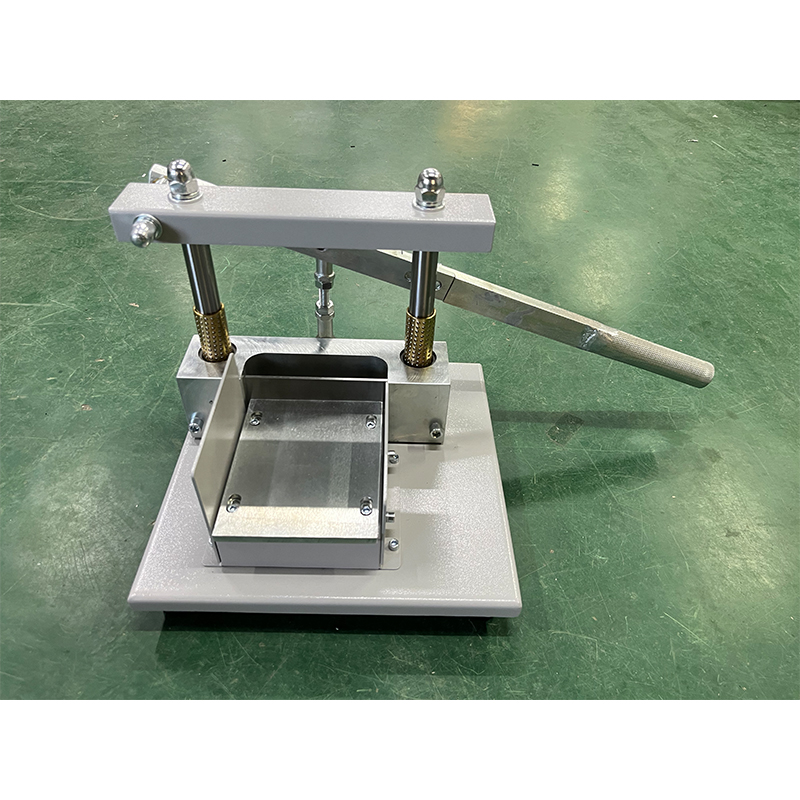

uv irradiation cross-linked machine factory

Secondly, the environmental impact of UV cross-linking is notably lower. Unlike solvent-based processes that release volatile organic compounds (VOCs), UV curing is often solvent-free, leading to fewer emissions and a reduced carbon footprint. This characteristic aligns with the global push towards sustainable manufacturing practices, making UV cross-linking an attractive option for environmentally-conscious companies.

Furthermore, the improved durability of UV-cured materials translates to enhanced product performance

. In applications ranging from automotive coatings to electronics, UV cross-linked products demonstrate superior resistance to scratches, chemicals, and UV light itself. This longevity not only benefits manufacturers through reduced return rates and customer complaints but also enhances consumer satisfaction.Applications in Various Industries

The applications of UV irradiation cross-linked machinery are diverse. In the automotive industry, UV-cured coatings provide protective finishes that withstand harsh environmental conditions. In electronics, UV cross-linking is critical for producing reliable circuitry and components that endure heat and moisture. The medical field also benefits from this technology, as UV-cured adhesives and coatings meet stringent regulatory requirements while providing biocompatibility.

Moreover, the packaging industry utilizes UV curing for inks and coatings that improve print quality and durability while maintaining safe food contact standards. The versatility of UV curing makes it an essential technology across multiple sectors, driving innovation and improving product reliability.

Future Outlook

As technology advances, the future of UV irradiation cross-linked machinery looks promising. Ongoing research aims to develop more efficient UV light sources, such as LED technology, which offer increased energy efficiency and a broader range of applications. Furthermore, the integration of artificial intelligence and machine learning into manufacturing processes will likely enhance the precision and efficiency of UV cross-linking, allowing for even greater customization of materials.

In conclusion, UV irradiation cross-linked machinery represents a significant advancement in manufacturing technology. Its ability to produce high-quality, durable materials quickly and sustainably positions it as a key player in the future of industrial production. As industries continue to embrace these innovations, the benefits of UV cross-linking will undoubtedly contribute to more efficient, environmentally friendly, and resilient manufacturing practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy