UV Irradiation Technology for Efficient Crosslinking in Various Applications

UV Irradiation Crosslinking Machine Revolutionizing Material Science

The UV irradiation crosslinking machine has emerged as a pivotal innovation in material science and engineering, offering advanced solutions for the modification of polymers and other materials

. This technology utilizes ultraviolet (UV) light to initiate crosslinking, a process that enhances the properties of materials, making them more resilient, durable, and versatile.Crosslinking refers to the chemical process where polymer chains are linked together, forming a three-dimensional network. This aggressive bonding not only improves mechanical strength but also enhances resistance to heat, chemicals, and environmental factors. Traditional methods of crosslinking often involve heat or chemical reagents, which can be time-consuming and may require extensive safety measures. In contrast, UV irradiation provides a faster, cleaner, and more efficient alternative.

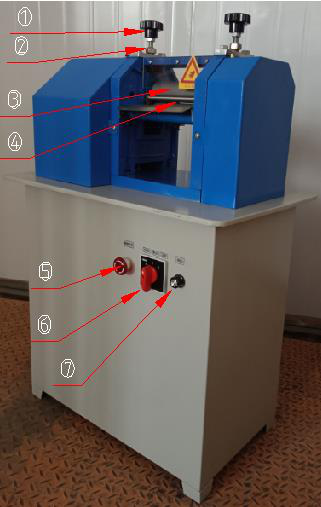

The operation of a UV irradiation crosslinking machine is relatively straightforward. It consists of a UV light source, a roller or conveyor system for material feeding, and a chamber designed to control environmental conditions. Materials such as coatings, adhesives, and films pass through the UV radiation zone, where the energy from the UV light triggers the photopolymerization process, leading to crosslinking. This allows manufacturers to achieve high throughput while maintaining product quality.

uv irradiation crosslinking machine

One of the standout benefits of using UV irradiation for crosslinking is the precision it offers. The process can be finely tuned to meet specific requirements, such as varying exposure times and intensities of UV light. Moreover, because it operates at room temperature, there is minimal thermal deformation, making it suitable for heat-sensitive materials.

Applications of UV crosslinking technology span various industries. In the automotive sector, it is used to enhance the durability of coatings and adhesives, ensuring that vehicles can withstand harsh conditions. In the medical field, UV crosslinked materials are employed in medical devices and implants, providing biocompatibility and longevity. Additionally, the packaging industry leverages this technology to produce robust films that maintain product integrity.

As industries continue to seek more efficient and sustainable manufacturing processes, the UV irradiation crosslinking machine stands out as a game-changer. Its ability to reduce production times and improve material properties highlights the essential role it plays in modern manufacturing. With ongoing advancements in UV technology, the future looks promising for this innovative solution, paving the way for improved materials across countless applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy