Manufacturers of UV Irradiation Crosslinking Equipment for Various Applications

Understanding UV Irradiation Crosslinking Machines and Their Manufacturers

In the modern manufacturing landscape, UV irradiation crosslinking machines play a pivotal role in enhancing the durability and performance of various materials. These machines use ultraviolet (UV) light to initiate a chemical reaction that links polymers together, creating a crosslinked network that significantly improves the properties of coatings, adhesives, and other materials. The demand for these machines has surged due to their efficiency and effectiveness in industrial applications, leading to the emergence of numerous manufacturers specializing in this technology.

The Mechanics of UV Crosslinking

UV irradiation crosslinking machines utilize high-intensity UV light to cure materials in a fast and efficient manner. The process involves exposing the material, typically formulated with photoinitiators, to UV light. Once exposed, the photoinitiators generate free radicals, which initiate the crosslinking of polymer chains. This results in a robust, resilient, and thermoset material that exhibits enhanced resistance to heat, chemicals, and environmental degradation.

This technology is prevalent across various industries, including automotive, aerospace, electronics, and healthcare. For example, in the automotive sector, UV crosslinking is used to improve the durability of coatings and adhesives, ensuring that they withstand extreme conditions without degrading.

The Rise of Manufacturers

With the increasing adoption of UV crosslinking technology, numerous manufacturers have emerged, each offering unique machines tailored to specific industrial needs

. These manufacturers range from large, established players in the equipment sector to innovative startups focused on developing cutting-edge UV technology.1. Established Players Companies such as Heraeus and IST Metz have built a reputation for producing high-quality UV curing systems. Their equipment is known for reliability, efficiency, and longevity, making them a preferred choice for many industries. These companies typically offer a full range of services, including machine design, installation, and ongoing support.

2. Innovative Startups Newer companies, like Exmore and UV-IT, are also making waves in the market with innovative solutions that push the boundaries of traditional UV curing technology. These manufacturers often emphasize sustainability and eco-friendliness, incorporating features such as energy-efficient lamps and recyclable materials in their designs.

uv irradiation crosslinking machine manufacturers

Factors to Consider When Choosing a Manufacturer

When selecting a UV irradiation crosslinking machine manufacturer, several factors must be taken into account

- Customization Options Different industries have unique requirements. A good manufacturer should offer customizable solutions to meet specific application needs.

- Technology and Innovation Look for manufacturers that invest in research and development. Advanced technology can significantly enhance efficiency and reliability.

- Support and Service After-sales support is crucial for maintaining equipment. A reliable manufacturer should provide comprehensive customer service, including maintenance and troubleshooting.

- Cost-Effectiveness While the initial investment can be significant, consider the long-term benefits of energy efficiency and reduced downtime.

Conclusion

UV irradiation crosslinking machines are revolutionizing the way materials are processed and enhanced across various industries. As the market continues to grow, the choice of manufacturer becomes increasingly critical. By carefully evaluating factors such as customization, technology, support, and cost, businesses can choose the right partner to enhance their production capabilities. With the right UV crosslinking machinery, companies can achieve unparalleled quality and performance, driving innovation and efficiency in their operations. As the industry evolves, staying informed about the latest advancements in UV technology will be essential for manufacturers aiming to maintain a competitive edge.

-

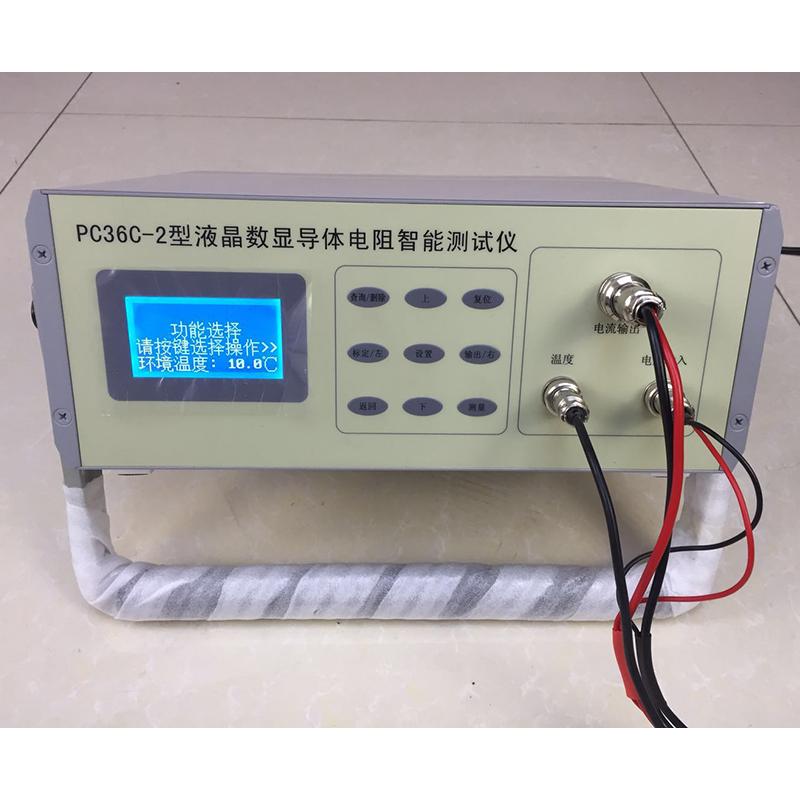

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy