vertical profile projector

Understanding the Vertical Profile Projector A Key Tool in Precision Measurement

In today's manufacturing and engineering landscape, precision measurement is paramount. One tool that has proven indispensable in achieving this level of accuracy is the vertical profile projector. This optical device, often referred to as a shadowgraph, plays a crucial role in the inspection of parts and components by magnifying the profile of an object and projecting it onto a screen.

A vertical profile projector operates by illuminating an object with a focused light source, creating a shadow that is then enhanced through optical lenses. The resulting image is magnified, allowing for detailed examination of complex profiles and contours. This capability is particularly beneficial for industries where precision is critical, such as aerospace, automotive, and mechanical engineering.

One of the primary advantages of using a vertical profile projector is its ability to measure intricate shapes with high accuracy. The device can provide two-dimensional representations of three-dimensional parts, allowing engineers and quality control personnel to assess features such as angles, radii, and dimensions with precision. This process helps ensure that manufactured components meet strict tolerances, thus preventing costly errors during production.

vertical profile projector

In addition to its measurement capabilities, the vertical profile projector enhances the visual analysis of components. The enlarged image projected onto the screen enables operators to observe subtle details that may not be visible to the naked eye. This feature is particularly useful in quality inspections, where even minor imperfections can lead to significant operational issues. By utilizing this tool, inspectors can identify flaws early in the manufacturing process, enabling corrective actions before the parts are assembled or shipped.

The versatility of the vertical profile projector extends beyond simple measurements. Many models come equipped with advanced features, such as digital readouts, software integration, and the ability to store measurements for future reference. This technological advancement allows for increased efficiency in the inspection process and facilitates easier data sharing among team members. Additionally, the incorporation of computer-aided measurement (CAM) tools has revolutionized how businesses handle quality control, leading to improved overall performance.

Despite its advantages, the effectiveness of a vertical profile projector relies heavily on the skill of the operator. Proper setup, calibration, and technique are essential to achieving accurate results. Operators must be well-trained in interpreting the projected images and understanding the instrument's limitations. Continuous education and hands-on training are crucial for maintaining high standards in measurement practices.

In conclusion, the vertical profile projector is a vital tool in the realm of precision measurement and quality control. Its ability to magnify and project intricate profiles allows for detailed inspections that are essential for maintaining product integrity in various industries. As technology continues to advance, the role of the vertical profile projector will likely evolve, integrating more sophisticated features that further enhance its efficacy in ensuring precision and quality in manufacturing processes.

-

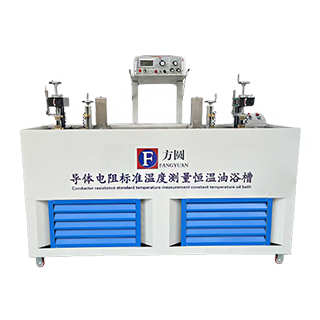

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy