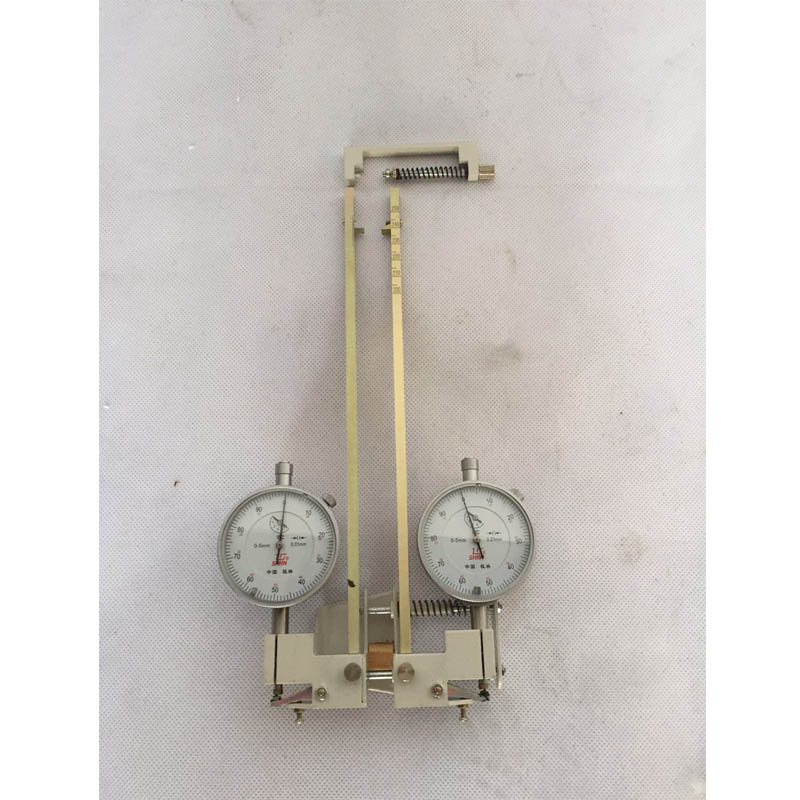

vertical profile projector

Understanding the Vertical Profile Projector A Key Tool in Precision Measurement

In the realm of precision measurement and quality control, the vertical profile projector, also known as a shadow graph or optical comparator, stands out as a pivotal tool for various industries, including manufacturing, engineering, and design. This optical measuring system plays a significant role in enhancing the accuracy and efficiency of dimensional inspection processes. By projecting the silhouette of a part onto a screen, it allows operators to compare the actual dimensions of a workpiece against its intended specifications.

How It Works

The principle behind the vertical profile projector is relatively straightforward yet ingenious. The device utilizes a strong light source to illuminate the object placed on its viewing platform. As light passes through or around the object, it creates a shadow that is then magnified and projected onto a frosted glass screen. This projection provides a clear, enlarged image of the part’s outline, which enables operators to take precise measurements.

Typically, the projector is equipped with a few essential components such as a lens, a stage for holding the workpiece, and a calibrated measurement scale. The optical elements in the projector ensure that the image is sharp and detailed, facilitating accurate analysis. Additionally, many modern profile projectors incorporate digital measuring capabilities, allowing for quicker data collection and enhanced functionality.

Applications in Industry

Vertical profile projectors are extensively used across various sectors for several applications. In the manufacturing industry, components such as gears, shafts, and other intricate parts are often inspected using this equipment. By accurately measuring features such as hole diameters, distances between points, and profiles of complex shapes, manufacturers can ensure that each component meets stringent quality standards.

Moreover, they are invaluable in the realms of automotive and aerospace engineering, where precision is paramount. Engineers rely on these projectors during the design phase to verify prototypes and during production to ensure consistency. The ability to identify defects and deviations early in the production process can save companies significant resources in terms of time and materials.

vertical profile projector

Advantages of Using Vertical Profile Projectors

One of the primary advantages of vertical profile projectors is the high degree of accuracy they provide. The optical nature of the measurement process minimizes the risk of error associated with mechanical measuring tools. Additionally, the ability to magnify the image allows operators to see even the smallest discrepancies, which is crucial in quality assurance.

Another benefit is the ease of use. Operators can quickly set up the projector and begin measuring, often without the need for extensive training. The visual nature of the measurements makes it intuitive, allowing for immediate comprehension of dimensional relationships. Furthermore, many projection systems now come with advanced software that can capture, record, and analyze measurements digitally, streamlining the inspection process.

Limitations and Considerations

While vertical profile projectors offer numerous advantages, they also come with some limitations. For instance, they are primarily suited for 2D measurements, which may not suffice in cases where comprehensive 3D inspection is required. Furthermore, careful alignment of the workpiece is essential; any misalignment can lead to inaccurate measurements.

Additionally, the initial investment cost for high-quality vertical profile projectors can be significant, potentially posing a barrier for smaller enterprises. However, the long-term benefits and cost savings derived from improved quality control and reduced waste often justify this initial expense.

Conclusion

In summary, the vertical profile projector is an indispensable tool in the field of precision measurement and quality assurance. Its ability to provide accurate, visual measurements has made it a preferred choice in various industrial applications. As technology advances, the integration of digital measurement capabilities and enhanced optical systems continues to expand the potential of vertical profile projectors, solidifying their relevance in modern manufacturing and engineering practices. Whether used for inspecting intricate components or ensuring design specifications are met, this device remains a cornerstone of quality control and assurance in today’s competitive landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy