Vertical Profile Projector Manufacturing Process and Key Industry Insights

Understanding Vertical Profile Projector Factories

Vertical profile projectors, also known as optical comparators, play a crucial role in the manufacturing and quality control sectors. These sophisticated machines are designed to project a magnified silhouette of a part onto a screen, allowing engineers and inspectors to compare the profile of the manufactured component against the original blueprint. As industries evolve, the demand for precision and efficiency in manufacturing processes continues to grow, leading to the establishment of specialized factories dedicated to the production and advancement of vertical profile projectors.

In these factories, cutting-edge technology and skilled craftsmanship come together. The manufacturing process begins with the procurement of high-quality optical components, including lenses and mirrors, which are essential for achieving precise projections. Engineers meticulously design the projection systems to ensure that they can accurately capture intricate details of various parts, from small components to larger assemblies.

Vertical profile projector factories utilize advanced manufacturing techniques, such as computer numerically controlled (CNC) machining and laser cutting, to produce the intricate parts of these machines. These processes not only enhance accuracy but also enable factories to maintain high production rates. Stringent quality control measures are implemented at every stage of production, ensuring that each projector meets the required specifications and performance standards.

vertical profile projector factories

Furthermore, the design of vertical profile projectors is continually evolving. Modern factories invest in research and development to incorporate the latest technological advancements, such as digital imaging and automation. These innovations enhance the capabilities of the projectors, allowing them to perform more complex measurements and analyses. Moreover, by integrating software solutions, operators can efficiently document measurements, reducing the likelihood of human error.

The global market for vertical profile projectors has seen increased demand, particularly in sectors such as aerospace, automotive, and medical devices, where precision is paramount

. As factories scale up their operations, they are also focusing on sustainability practices, aiming to reduce waste and energy consumption during manufacturing.In conclusion, vertical profile projector factories are at the forefront of ensuring quality and precision in manufacturing processes. By combining advanced technology, skilled labor, and sustainable practices, these factories are poised to meet the growing demands of various industries while promoting innovation and efficiency in the field of optical measurement.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

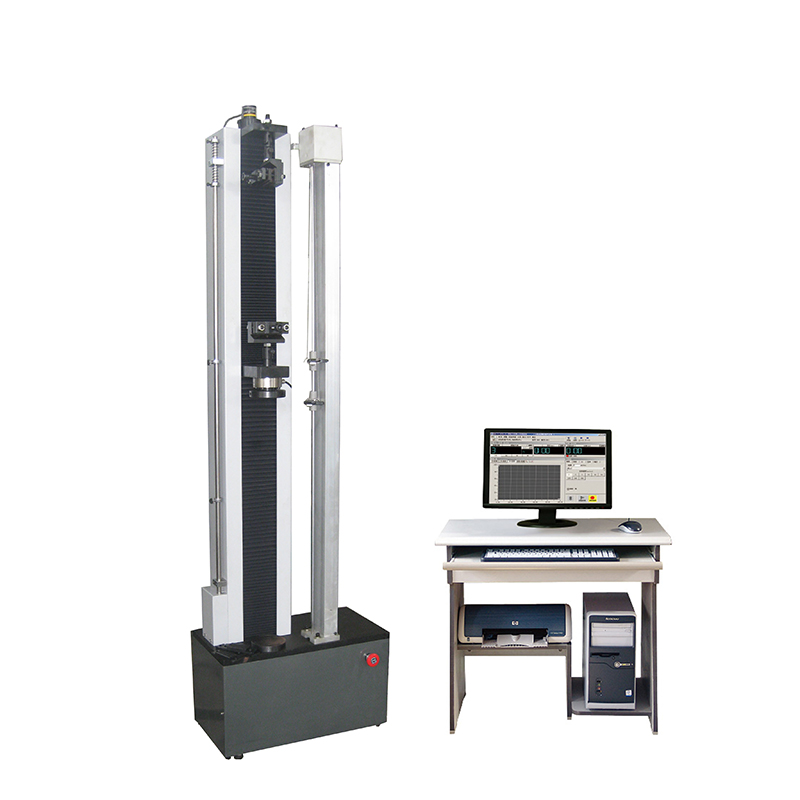

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy