Exporter of Winding and Torsion Testing Equipment for Quality Assurance Solutions

The Role of Winding and Torsion Testers in Modern Manufacturing

In the fast-evolving landscape of manufacturing, precision and quality control have emerged as vital components that determine the success of products across various industries. One critical element in this domain is the winding and torsion tester, a specialized instrument designed to evaluate the integrity and performance of wound products. As globalization continues to shape the manufacturing sector, the export of such testing equipment has gained significant traction. This article delves into the importance of winding and torsion testers, their applications, and the implications of their export.

Understanding Winding and Torsion Testers

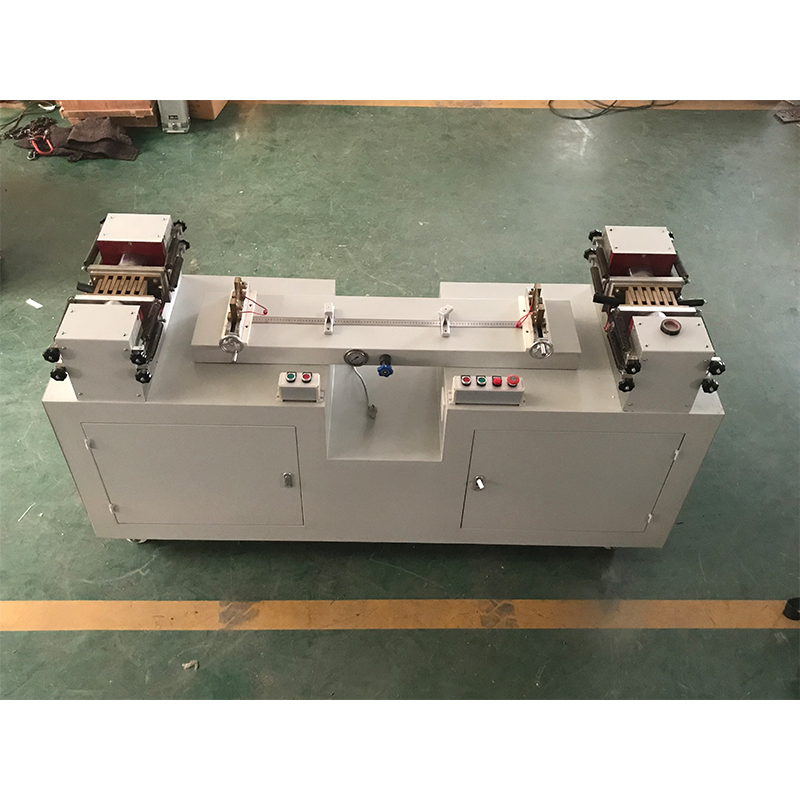

Winding and torsion testers are sophisticated machines that are used to simulate and measure the forces acting on spooled materials, such as wires, cables, and fibers, during their use. These testers assess key parameters including tensile strength, torsional rigidity, and overall durability. The ability to accurately gauge these factors is paramount for manufacturers aiming to produce reliable and long-lasting products.

In practical applications, winding testers evaluate the circular coils and layers of wires in motors and transformers to ensure that they meet specified tension and torque requirements. Torsion testers, on the other hand, are pivotal in determining how materials behave when twisted, which is especially important for industries that rely on components subject to dynamic forces, such as automotive and aerospace sectors.

Applications Across Industries

Winding and torsion testers find their utility across a variety of industries. In the automotive industry, for example, they are crucial for testing components such as ignition wires and electrical cables that must withstand extreme conditions. In the aerospace sector, these testers ensure the reliability of components used in airframes and engines, where failure is not an option.

Moreover, the telecommunications industry benefits from these testers as well, particularly in the manufacturing of fiber optic cables

. The ability to withstand torsional forces is critical in ensuring that these cables maintain performance over time, especially in varying environmental conditions.winding and torsion tester exporter

Quality Control and Product Development

The integration of winding and torsion testing in the manufacturing process significantly enhances quality control. By identifying defects and weaknesses in the early stages of production, companies can mitigate risks, reduce waste, and ultimately save on costs. Furthermore, the data generated from these tests enable engineers to refine product designs and materials, fostering innovation and improved product performance.

As industries strive for greater efficiency and sustainability, the emphasis on testing and quality assurance methods like winding and torsion testing has never been more pronounced. Manufacturers are increasingly recognizing the value of investing in this technology to keep pace with market demands and regulatory standards.

The Export of Testing Equipment

With the growing global marketplace, the export of winding and torsion testers has seen a steady rise. Countries with advanced manufacturing capabilities are increasingly supplying these technological solutions to emerging markets, where manufacturing infrastructures are developing rapidly. This exchange of technology not only enhances the quality of products in these countries but also facilitates international collaborations that drive innovation.

The demand for high-quality winding and torsion testers is driven by the growing need for reliable manufacturing processes across different sectors. Companies that specialize in exporting this equipment often find themselves at the forefront of technological advancements. They contribute not only by supplying machines but also by offering essential support and training services that empower manufacturers to optimize their operations.

Conclusion

In summary, winding and torsion testers are indispensable tools in the realm of modern manufacturing. They play a pivotal role in ensuring product quality, fostering innovation, and enabling manufacturers to meet the demands of increasingly complex markets. As the export of this testing equipment continues to expand, it is essential for businesses to recognize the importance of investing in precise testing solutions to maintain their competitive edge. The future of manufacturing will increasingly depend on the reliability and efficiency provided by advanced testing technologies, making winding and torsion testers a cornerstone of production excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy