Winding and Torsion Testing Equipment Manufacturer for Precision Engineering Solutions

The Importance of Winding and Torsion Testers in Manufacturing

In the world of engineering and manufacturing, precision and quality control are of paramount importance. Whether a company is producing electrical components, textiles, or metallic structures, ensuring the integrity of materials and products is essential for safety and functionality. One of the key tools used in this process is the winding and torsion tester, which measures the mechanical properties of materials subjected to twisting and winding forces. This article will explore the significance of winding and torsion testers in modern manufacturing, their applications, and how manufacturers select the right factory for these essential testing machines.

Understanding Winding and Torsion Testing

Winding involves the coiling of materials such as wire, rope, and tape, while torsion testing assesses the ability of a material to withstand twisting forces. The testing process provides valuable data on how a material will perform under stress, which is crucial for applications ranging from aerospace to electronics. By simulating real-world conditions, winding and torsion testers allow manufacturers to identify potential weaknesses in their products, ultimately leading to better performance and safety standards.

Applications in Various Industries

Winding and torsion testers are employed in numerous industries. In the textile industry, for instance, these testers evaluate the durability of yarns and fabrics, helping manufacturers understand how their products will behave during production and in the final application. In the electronics sector, winding testers are essential for assessing the quality of inductors and transformers, which are critical components in modern devices. Similarly, in the aerospace and automotive industries, torsion tests are essential for materials used in structural components, ensuring they can withstand the stresses encountered during operation.

Selecting a Reliable Tester Factory

When it comes time to invest in winding and torsion testing equipment, choosing the right factory is critical. Manufacturers need to consider several factors when selecting a supplier, including

winding and torsion tester factory

1. Experience and Reputation Look for factories that have been in the industry for a significant period and have a track record of producing high-quality testing machines. Reading customer reviews and testimonials can provide insights into a factory’s reliability and the performance of its products.

2. Customization Options Every manufacturing process is unique, and often, a one-size-fits-all approach is not viable. A reputable factory should offer customization options tailored to the specific testing needs of different materials and applications.

3. Technological Innovation The manufacturing landscape is continuously evolving, and factories that invest in the latest technology tend to produce more accurate and efficient testing machines. Look for suppliers who use advanced materials and innovative designs in their equipment.

4. After-Sales Support A factory that provides comprehensive after-sales support, including training, maintenance, and repair services, can be invaluable. This support ensures that companies can maximize the lifespan of their testing equipment and maintain consistent quality control.

5. Regulatory Compliance Ensure that the factory meets international standards for quality and safety. Compliance with ISO and other industry standards is crucial for guaranteeing the reliability of the testing machines.

Conclusion

In the ever-evolving world of manufacturing, the importance of winding and torsion testers cannot be understated. They play a crucial role in ensuring that materials can withstand the pressures they are subjected to in real-life applications. As manufacturers continuously strive for higher quality and performance standards, investing in reliable testing equipment from a reputable factory is a step toward achieving these goals. By understanding the significance of these testers and choosing the right supplier, manufacturers can enhance their production processes and ultimately deliver superior products to the market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

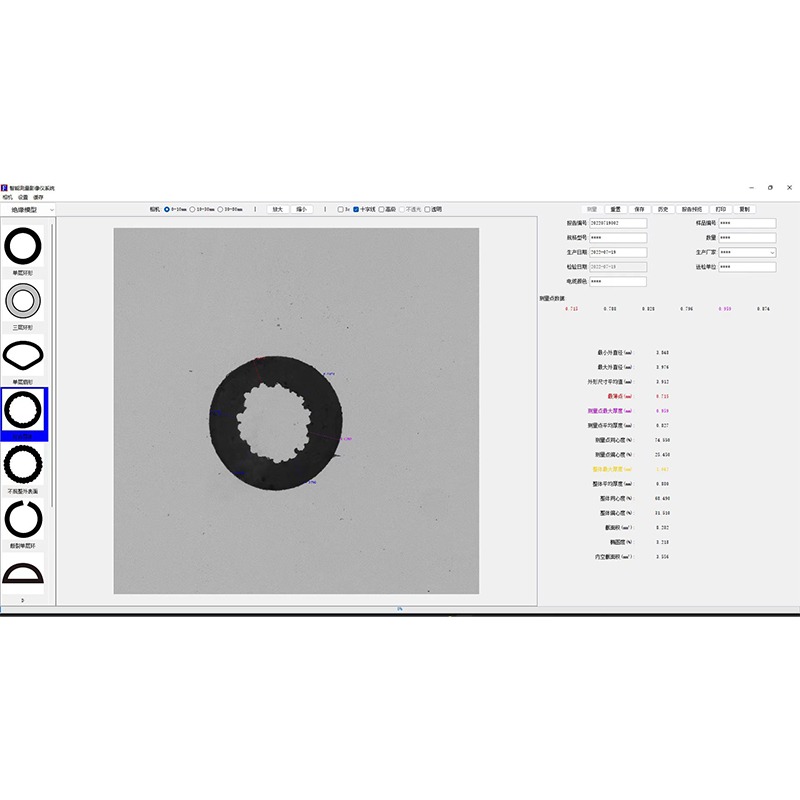

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy