winding and torsion testing machine companies

Understanding Winding and Torsion Testing Machine Companies

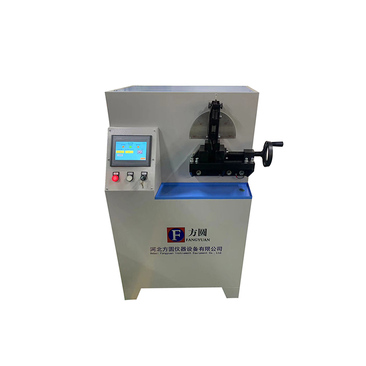

In the realm of engineering and manufacturing, the importance of testing machinery cannot be overstated. Specifically, winding and torsion testing machines have become essential tools for various industries, including aerospace, automotive, textile, and electronics. These machines are designed to evaluate the mechanical properties of materials and components, ensuring that they meet the required standards for safety and performance. As a result, the companies that specialize in producing these testing machines play a crucial role in the quality assurance processes of numerous industries.

The Role of Winding and Torsion Testing Machines

Winding testing machines are primarily used to assess the tensile strength and durability of materials. They apply a controlled tension to a sample, simulating the forces that the material would encounter during application. This type of testing is vital for materials used in cables, ropes, and other applications where tensile strength is critical.

On the other hand, torsion testing machines evaluate how materials respond to twisting forces. This is particularly important in industries where parts are subject to rotational forces, such as in rotating machinery or structural applications. By analyzing how materials behave under torsion, engineers can make informed decisions about the suitability of specific materials for various applications.

Key Players in the Market

Several companies dominate the market for winding and torsion testing machines. These firms vary in size, product range, and technology, but they all contribute significantly to the field of material testing. Some of the leading manufacturers include

1. Instron A renowned name in materials testing, Instron offers a wide range of machines, including those for winding and torsion testing. Their equipment is known for its precision and reliability, making it a popular choice among engineers and researchers.

2. Zwick Roell Based in Germany, Zwick Roell is another key player in the testing machine market. Their machines are designed for a variety of applications, and they provide customized solutions to meet specific customer needs. The company's focus on innovation ensures that their products integrate the latest technologies.

winding and torsion testing machine companies

3. Shimadzu With a strong presence in the international market, Shimadzu manufactures high-quality testing machines, including those for torsion testing. Their commitment to research and development enables them to create cutting-edge equipment that adheres to industry standards.

4. MTS Systems Corporation MTS is known for its advanced testing solutions and software. Their machines are widely used in academic and industrial research, highlighting their significance in material testing across various sectors.

5. Tinius Olsen This company has a longstanding reputation for producing reliable testing machines. Their winding and torsion testing equipment is used globally, and they focus on providing excellent customer support and training.

Quality Assurance and Industry Standards

One of the main reasons for the growing demand for winding and torsion testing machines is the need for quality assurance. As industries face increasing regulations and consumer expectations, manufacturers must ensure that their products are safe and reliable. Testing machines help in validating that materials can withstand the forces they will encounter in real-world applications.

Additionally, many industries follow strict standards set by national and international organizations, including ASTM, ISO, and SAE. These organizations provide guidelines on how to conduct tests, which helps ensure consistency and reliability in testing results. Companies that produce winding and torsion testing machines often design their equipment to comply with these standards, making it easier for manufacturers to conform to regulatory requirements.

Conclusion

In summary, winding and torsion testing machine companies play a vital role in the quality assurance processes of many industries. These machines not only help ensure the reliability and safety of materials and components but also foster innovation by allowing engineers to explore new materials and designs. As technology continues to advance, the importance of precise and reliable testing machines will only increase, paving the way for safer and more efficient products in the market. The collaboration between manufacturers and testing machine companies is crucial for driving advancements in material science and engineering practices, ultimately benefiting consumers and industries alike.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy