winding and torsion testing machine manufacturer

Winding and Torsion Testing Machine Manufacturers A Vital Component of Quality Assurance

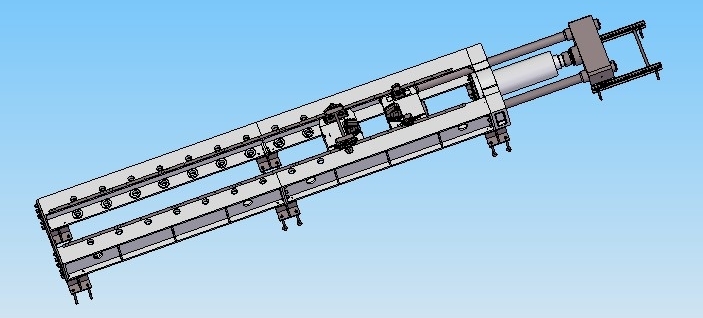

In the realm of material testing, winding and torsion testing machines play a crucial role in ensuring the quality and durability of products, particularly in the cable, wire, and textile industries. These specialized machines are designed to evaluate the mechanical properties of materials by simulating the stresses they encounter during their lifecycle. As such, manufacturers of winding and torsion testing machines are integral to the development of reliable and high-performance products.

Winding testing primarily assesses the resistance of materials to cyclic loading, which is especially important for components that will undergo repeated twisting or bending. The process involves wrapping a sample around a spindle and applying controlled tension while measuring the material's ability to withstand deformation. This testing is vital for ensuring that cables and wires can handle the demands of their application—whether in electrical installations, automotive systems, or telecommunications.

On the other hand, torsion testing focuses on the material's response to rotational forces. Manufacturers utilize torsion testing machines to apply torque to a specimen until it fails. The results provide critical data on the shear strength and elasticity of the material. This information is not only essential for quality control but also for product development, allowing designers to optimize materials for specific applications.

winding and torsion testing machine manufacturer

Leading winding and torsion testing machine manufacturers invest heavily in research and development to stay ahead of industry trends and technological advancements. They strive to incorporate sophisticated features, such as digital data acquisition systems, automated testing sequences, and enhanced graphical interfaces, which facilitate accurate and efficient testing processes. The integration of software solutions enables real-time analysis of data, helping operators make informed decisions quickly.

Moreover, as industries push towards sustainability, manufacturers are also responding by developing eco-friendly testing machines that reduce environmental impact. The ability to perform accurate tests with minimal waste and energy consumption is becoming increasingly important, and manufacturers are rising to this challenge.

Additionally, customer service and support are vital aspects of a manufacturer’s reputation. Training and guidance for operators, regular maintenance services, and the availability of spare parts are crucial for ensuring longevity and optimal performance of testing machines. Manufacturers that prioritize their clients' needs are better positioned to foster long-term relationships.

In conclusion, winding and torsion testing machine manufacturers are pivotal in safeguarding product quality across multiple industries. By advancing technology, enhancing testing methods, and maintaining strong customer relations, they contribute significantly to the reliability and performance of products that we rely on daily. As materials continue to evolve, the importance of these testing machines will only grow, underpinning the quest for quality and innovation in manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy