winding and torsion testing machine suppliers

Winding and Torsion Testing Machine Suppliers An Overview

In today's competitive manufacturing landscape, the testing of materials and components has become crucial for ensuring quality and reliability. One of the key areas of testing involves the evaluation of materials under specific stresses and twisting forces, which is where winding and torsion testing machines come into play. These sophisticated machines provide essential data on the mechanical properties of materials, making them indispensable in various industries including aerospace, automotive, construction, and textiles.

Understanding Winding and Torsion Testing Machines

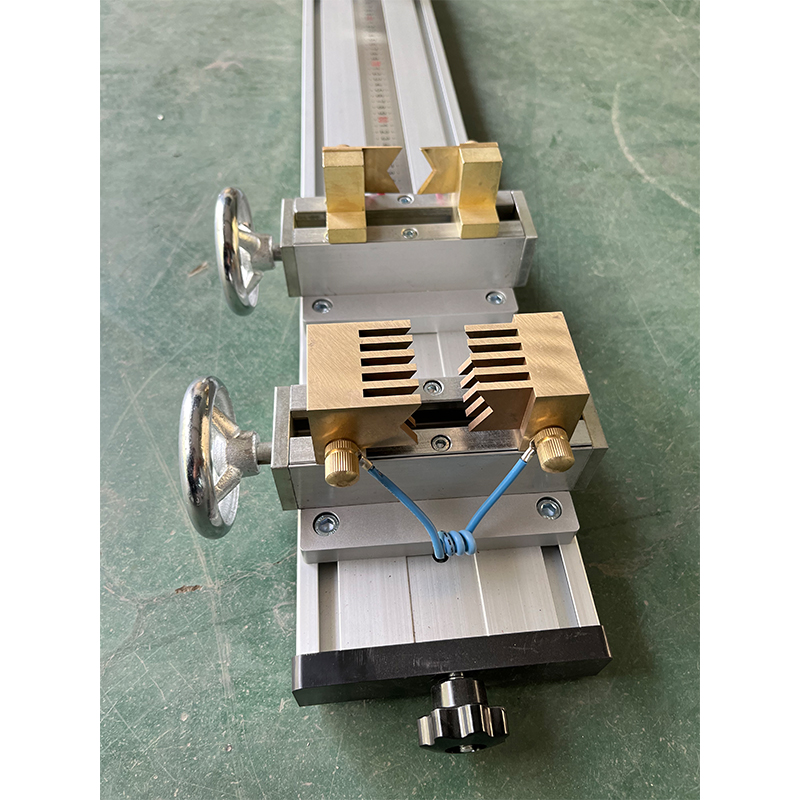

Winding testing machines are designed to assess the strength and endurance of materials such as fibers, wires, and cables when subjected to winding stresses. Similarly, torsion testing machines evaluate the performance of materials under twisting forces, which is particularly important for components like shafts, rods, and fasteners. The data obtained from these tests can help manufacturers identify potential weaknesses, optimize material selection, and improve product designs.

Various parameters can be measured using these machines, such as tensile strength, fatigue resistance, and elongation. The results are crucial for quality assurance processes, as they help ensure that materials can withstand operational demands and safety requirements.

Importance of Choosing the Right Supplier

Selecting a reliable supplier for winding and torsion testing machines is vital for enhancing production quality. The right supplier will not only provide advanced machines that meet industry standards but also offer good technical support and after-sales service. Here are some key criteria to consider when choosing a supplier

1. Experience and Reputation A supplier with a long-standing reputation and extensive experience in the field is more likely to offer high-quality machines. Research into the supplier’s history and customer feedback can provide valuable insights.

winding and torsion testing machine suppliers

2. Product Range Suppliers with a diverse range of testing machines can better cater to the specific needs of different industries. It's essential to choose a supplier that offers customization options to align the machines with the intended applications.

3. Technical Support and Service A trustworthy supplier should provide robust technical support and timely maintenance services. This is crucial not only during the purchasing phase but also throughout the machine's operational life.

4. Innovative Technology As technology evolves, so do testing methodologies. Suppliers who invest in research and development tend to provide more advanced and efficient machines. It is beneficial to look for suppliers that incorporate the latest technologies in their products.

5. Certifications and Compliance Ensuring that the machines comply with relevant international standards and regulations is critical. A reputable supplier should provide documentation verifying the compliance of their machines.

Notable Suppliers in the Market

Several companies have established themselves as leaders in the field of winding and torsion testing machines. For instance, manufacturers such as TestResources, Instron, and ZwickRoell have been noted for providing high-quality testing equipment and innovative solutions tailored to the needs of various industries. Their commitment to quality and performance has made them trusted partners for numerous businesses.

Conclusion

Winding and torsion testing machines play an essential role in the manufacturing process by ensuring that materials meet the necessary strength and reliability standards. Choosing the right supplier helps companies enhance their production quality and ultimately their competitiveness in the market. By considering factors such as reputation, product range, technical support, and compliance, businesses can find a supplier that not only meets their current needs but also supports their future growth and innovation. Investing in high-quality testing machines and partnering with trusted suppliers paves the way for improved product performance and operational excellence in today’s ever-evolving industrial landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy