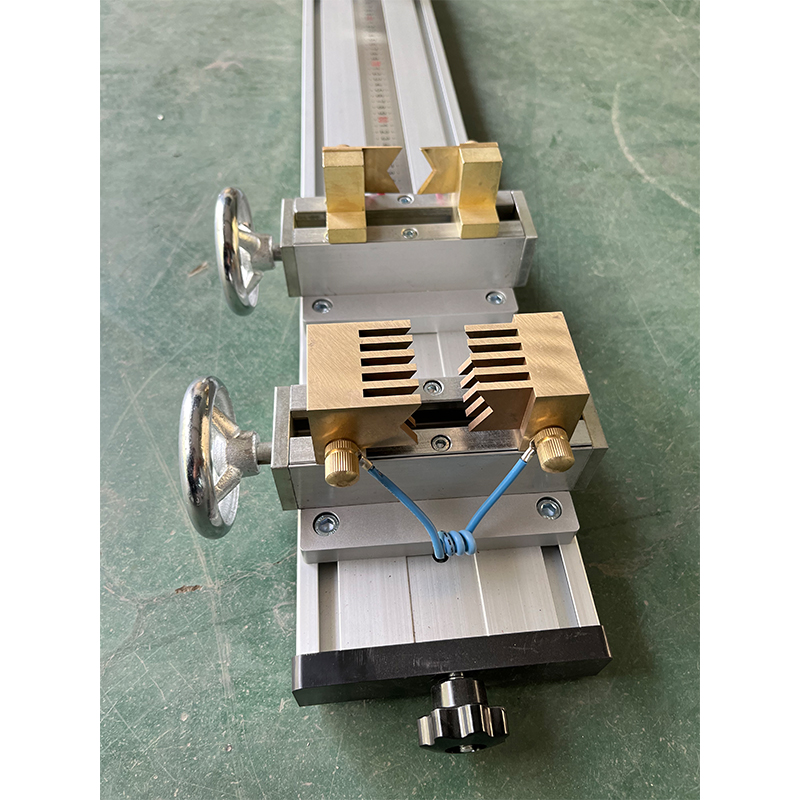

wire bending test machine

Wire Bending Test Machine An Essential Tool for Quality Assurance

In the realm of materials testing, the wire bending test machine plays a crucial role in assessing the mechanical properties and durability of wire products. This specialized equipment is designed to evaluate how well a wire can withstand bending and stress before it reaches its breaking point. With applications spanning various industries, including automotive, aerospace, and construction, the wire bending test machine is indispensable for ensuring product reliability and safety.

The primary purpose of the wire bending test machine is to simulate real-world conditions that the wire might encounter during its service life

. By subjecting the wire to repetitive bending cycles, manufacturers can gather valuable data on its fatigue resistance and overall resilience. This testing process is vital, as it helps identify potential flaws or weaknesses in the wire, which could lead to catastrophic failures if left undetected.Modern wire bending test machines come equipped with advanced features, such as programmable controls and digital displays, allowing for precise monitoring of the testing process. Operators can set specific parameters, including bend angle, speed, and cycle count, tailoring the test to meet the unique requirements of different wire types. This level of customization enhances the accuracy of the results, providing manufacturers with reliable insights into their products' performance.

wire bending test machine

In addition to assessing the wire's structural integrity, these machines can also evaluate its surface properties. By examining the wire's appearance before and after testing, manufacturers can identify issues like cracking, deformation, or surface wear that may compromise the wire's functionality. Such assessments are essential in industries where the integrity of components is paramount, as in the case of automotive suspension systems or aerospace components.

Furthermore, the wire bending test machine complies with various industry standards, such as ASTM and ISO, ensuring that the testing processes meet global quality assurance benchmarks. By adhering to these standards, manufacturers can confidently market their products, knowing they have undergone rigorous testing and meet safety regulations.

In conclusion, the wire bending test machine is a vital investment for manufacturers looking to ensure the quality and reliability of their wire products. Through rigorous testing and analysis, this machine not only helps identify potential issues but also contributes to the advancement of material science, ultimately leading to safer and more durable products for end-users. As industries continue to evolve, the importance of such testing equipment will only grow, reinforcing its role in maintaining high standards of excellence in manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy