wire repeated bending test machine factories

The Importance of Wire Repeated Bending Test Machines in Quality Control and Manufacturing

In the world of manufacturing, especially in industries that rely heavily on metal components and wire products, ensuring the quality and durability of materials is of paramount importance. One critical aspect of quality assurance is the mechanical testing of materials, where wire repeated bending test machines come to the forefront. This article explores the significance of these machines, their operation, and their impact on manufacturing practices.

Understanding Wire Repeated Bending Test Machines

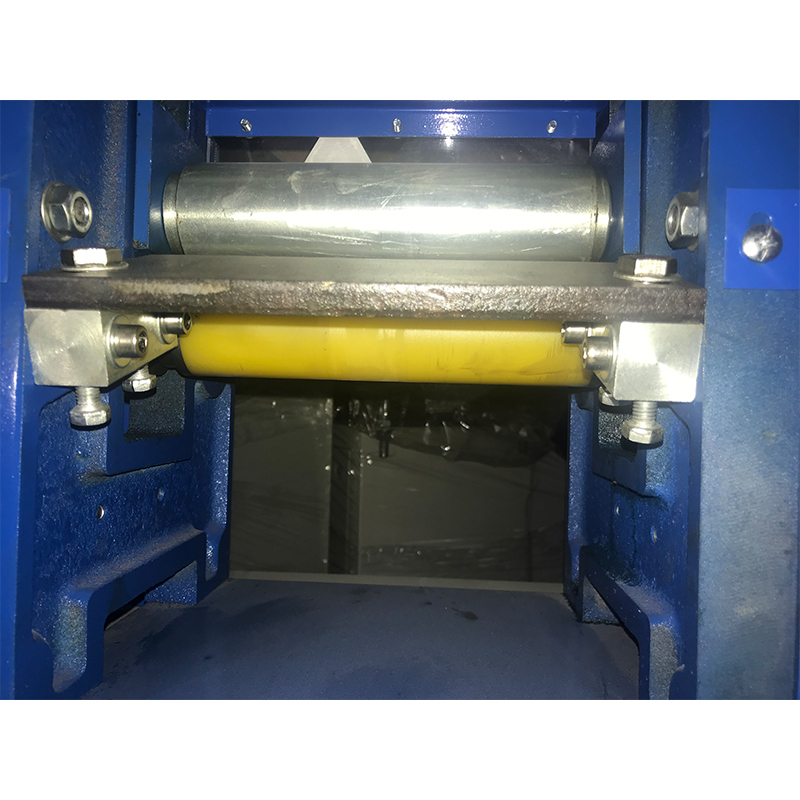

Wire repeated bending test machines are specialized equipment designed to evaluate the endurance of wire materials under repetitive bending stresses. These machines simulate the everyday conditions that wires and metals may experience in various applications, such as in automotive, construction, and electronics. By subjecting wires to repeated bending cycles, manufacturers can assess factors such as fatigue strength, ductility, and overall durability.

The fundamental operation of a wire bending test machine involves clamping a wire sample in place and repeatedly bending it to a specified angle or radius. The machine measures the number of cycles the wire withstands before failure, providing valuable data that can influence design and manufacturing processes. Advanced models may include features such as programmable bending angles, variable speeds, and digital data recording to streamline testing and analysis.

Importance in Quality Control

The primary role of these machines is within quality control protocols. Each industry has specific standards and regulations governing the mechanical properties of materials used in production. By employing wire repeated bending test machines, manufacturers can ensure that their products meet or exceed these regulations.

1. Identifying Weaknesses The primary advantage of using a bending test machine is its ability to highlight potential weaknesses in wire materials. During the testing process, manufacturers can identify flaws, inconsistencies, or weaknesses that may not be visible through standard inspection methods.

2. Material Selection and Improvement The data gathered from repeated bending tests can guide manufacturers in selecting the appropriate materials for their products. It can also inform decisions about alloy compositions, heat treatments, and other modifications that enhance material performance.

3. Reducing Warranty Claims By ensuring that products can withstand the rigors of their intended applications, manufacturers can significantly reduce the likelihood of warranty claims due to material failure. This proactive approach not only saves costs but also enhances brand reputation and customer satisfaction.

wire repeated bending test machine factories

Applications Across Various Industries

Wire repeated bending test machines find applications across multiple industries.

- Automotive In the automotive industry, wire components are critical for everything from electrical systems to structural elements. Testing wire harnesses and components ensures they can endure the vibrations, stresses, and environmental factors encountered during their lifespan.

- Electronics The demand for high reliability in electronic devices necessitates rigorous testing of wires and connectors. Bending tests help ensure that these components can withstand repeated use without failure, vital for consumer electronics, medical devices, and aerospace applications.

- Construction Wire products such as rebar and wire meshes used in construction must exhibit exceptional durability. Continuous bending tests help ensure these materials can handle the stresses of construction environments without compromising structural integrity.

Innovations in Testing Technology

Technological advancements have also influenced the development and functionality of wire repeated bending test machines. Modern machines are incorporating features such as automated data analysis, integration with computer systems for real-time monitoring, and user-friendly interfaces for easy operation. These innovations increase efficiency and accuracy, allowing for quicker turnaround times on test results.

Conclusion

Wire repeated bending test machines represent a crucial aspect of quality assurance in manufacturing sectors that utilize wire materials. By rigorously testing the durability of these materials, manufacturers can significantly enhance product quality, reduce failure rates, and ensure compliance with industry standards. As technology continues to evolve, these machines will undoubtedly play an even more pivotal role in the quest for excellence in manufacturing practices, underpinning the reliability and trustworthiness of products that rely on metal components.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy