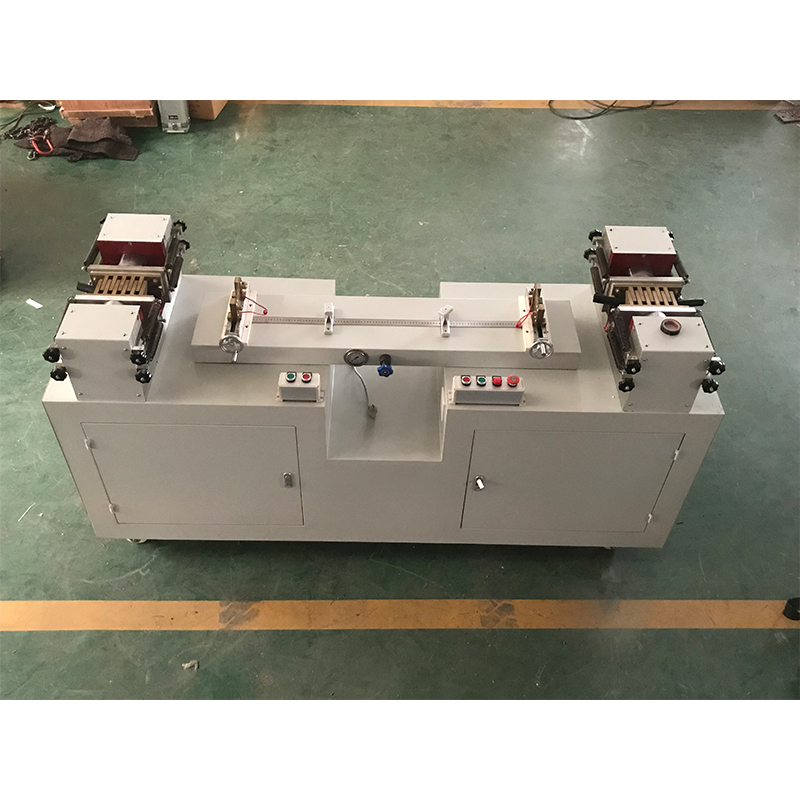

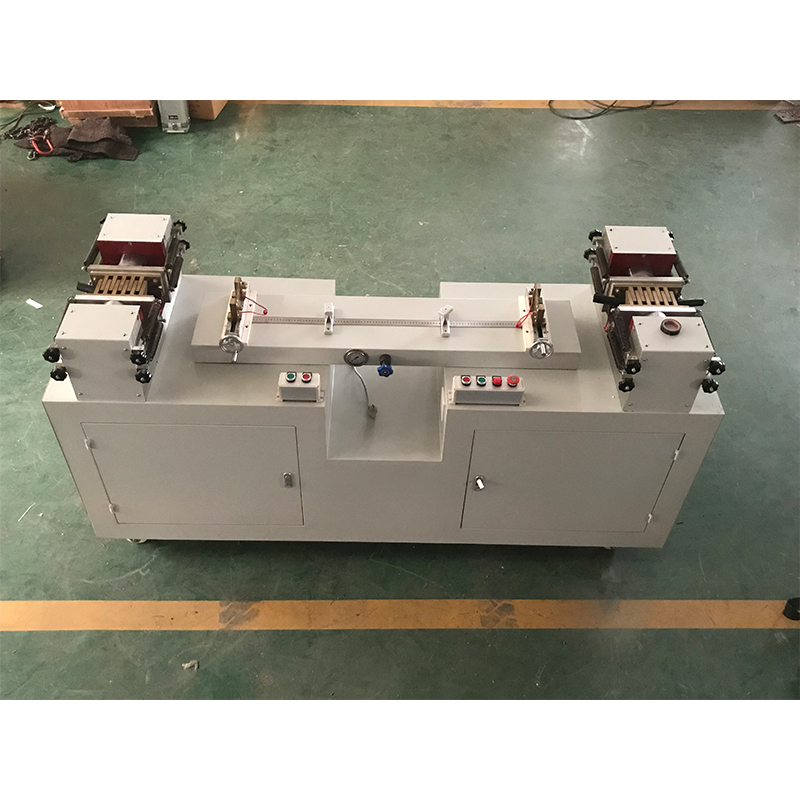

YDQ-2500 Hydraulic Conductor Fixture: Secure Line Installation Tool

Unlocking Precision and Durability: The YDQ-2500 Hydraulic Conductor Fixture in Modern Testing

In the rigorous world of material science and engineering, particularly within the wire and cable industry, the integrity of conductor materials is paramount. Ensuring their reliability under extreme stress and various environmental conditions is not merely a quality control measure but a critical safety prerequisite. This necessitates specialized testing equipment capable of delivering unparalleled precision and consistent performance. The YDQ-2500 Hydraulic Conductor Fixture stands as a benchmark in this domain, designed to securely hold and test conductors with hydraulic force, replicating real-world operational stresses. Its advanced design addresses the evolving demands of high-strength conductor testing, minimizing slippage and maximizing data accuracy, which are crucial for evaluating new alloy compositions, optimizing existing designs, and ensuring compliance with stringent international standards like ASTM and IEC. This fixture is a cornerstone for R&D departments and quality assurance laboratories striving for excellence in conductor analysis.

Industry Trends and Technological Imperatives

The global energy transmission and distribution landscape is undergoing rapid transformation, driven by the increasing integration of renewable energy sources and the expansion of smart grids. This paradigm shift demands conductors with enhanced mechanical strength, improved fatigue resistance, and superior thermal performance. Consequently, the demand for advanced testing methodologies and equipment, such as the YDQ-2500 Hydraulic Conductor Fixture, has surged. Industry trends indicate a lean towards automated testing systems, non-destructive evaluation techniques, and the use of digital twins for predictive maintenance, all of which rely on highly accurate initial material characterization. Furthermore, environmental regulations are pushing for lighter, more efficient materials, increasing the complexity and precision required in testing. Manufacturers are continuously innovating to meet these challenges, with a focus on enhancing fixture longevity, reducing maintenance, and ensuring compatibility with a wide range of conductor types, from conventional copper and aluminum to advanced composite materials.

The shift towards higher voltage transmission and smarter grid infrastructure has placed unprecedented demands on the mechanical robustness of electrical conductors. This necessitates testing equipment that can apply and sustain precise tensile loads, ensuring that conductors can withstand environmental stressors, installation strains, and long-term operational fatigue. The YDQ-2500 Hydraulic Conductor Fixture is at the forefront of this evolution, offering the precision and stability required for critical tests like ultimate tensile strength (UTS) and elongation, which are fundamental to assessing conductor reliability. The fixture's design also incorporates features that cater to the testing of new-generation conductors, including those with intricate stranding patterns or composite cores, reflecting the industry's move towards materials that balance conductivity with exceptional mechanical properties.

Key Technical Specifications and Performance Parameters

Understanding the precise capabilities of the YDQ-2500 Hydraulic Conductor Fixture is essential for optimizing testing protocols and ensuring accurate data acquisition. This fixture is engineered to handle substantial tensile forces, making it suitable for a wide array of conductor types and sizes. Below is a detailed table outlining its core technical parameters, derived from extensive engineering specifications and performance benchmarks, which underscore its robust design and high-precision capabilities. These specifications are critical for laboratories and manufacturing facilities in determining the fixture's suitability for their specific testing requirements, ranging from routine quality control to advanced material research and development.

| Parameter | Specification | Notes |

|---|---|---|

| Max. Test Load Capacity | 2500 kN (250 Tons) | Designed for heavy-duty conductor testing. |

| Clamping Method | Hydraulic Gripping | Ensures secure, non-slip hold. |

| Applicable Conductor Diameter | Ø 10 mm - Ø 100 mm (customizable) | Versatile range for various conductor types. |

| Jaw Opening/Closing Speed | Adjustable, typically 0.5-2 mm/s | Controlled operation for safety and precision. |

| Hydraulic System Pressure | Up to 25 MPa | High-pressure system for robust clamping. |

| Operating Temperature Range | -10°C to +50°C | Suitable for standard lab environments. |

| Material Construction | High-strength alloy steel (e.g., 42CrMo) | Ensures durability and long service life. |

| Weight (Approx.) | ~ 800 kg (per set of jaws) | Indicates robust, heavy-duty construction. |

| Typical Service Life | 10+ Years (with proper maintenance) | High return on investment. |

The hydraulic gripping mechanism of the YDQ-2500 Hydraulic Conductor Fixture is designed for unparalleled clamping force, evenly distributing pressure across the conductor's surface. This prevents localized deformation or premature failure at the gripping point, ensuring that the test results accurately reflect the material properties of the conductor itself, not an artifact of the clamping. The versatility in handling various conductor diameters is achieved through interchangeable jaw inserts, which can be custom-designed for specific conductor profiles, including those with non-circular cross-sections. This adaptability makes the YDQ-2500 a cornerstone for laboratories dealing with a diverse range of cable and wire products, from overhead transmission lines to specialized industrial cables.

Precision Manufacturing and Rigorous Quality Assurance

The manufacturing of the YDQ-2500 Hydraulic Conductor Fixture is a testament to precision engineering, adhering to the highest industry standards to ensure its reliability and longevity. The process begins with the selection of premium alloy steels, such as 42CrMo, renowned for its exceptional strength, toughness, and wear resistance, crucial for components under immense stress. Key components like the main body and hydraulic cylinders undergo advanced forging processes to refine their grain structure, enhancing mechanical properties and eliminating internal defects. This is followed by meticulous CNC machining, achieving micron-level tolerances for critical interfaces, ensuring smooth hydraulic operation and perfect alignment, which is paramount for preventing slippage during high-load tests.

Post-machining, components of the YDQ-2500 Hydraulic Conductor Fixture undergo specialized heat treatments, including quenching and tempering, to achieve optimal hardness and ductility, preventing premature wear and fatigue under repetitive loading cycles. Surface treatments like nitriding or chrome plating are then applied to enhance corrosion resistance and reduce friction, extending the fixture's operational life, particularly in challenging industrial environments. Every single component, from the smallest seal to the largest structural element, is subjected to stringent quality control checks. This includes non-destructive testing (NDT) methods like ultrasonic and magnetic particle inspection to detect any subsurface flaws, along with precise dimensional verification using CMM (Coordinate Measuring Machine) technology.

Before final assembly, each hydraulic circuit is pressure-tested far beyond its operational limits to ensure leak-proof performance and structural integrity. The assembled YDQ-2500 Hydraulic Conductor Fixture then undergoes a comprehensive calibration process, verified against international standards such as ISO 7500-1 and ASTM E4, guaranteeing its force accuracy and repeatability. This rigorous manufacturing and inspection regimen ensures that the fixture not only meets but often exceeds the demanding requirements of industries like petrochemicals, metallurgy, and water supply and drainage, where equipment reliability and safety are non-negotiable. Its robust construction and anti-corrosion treatments also contribute to significant energy savings by minimizing operational downtime and replacement costs over a typical service life exceeding 10 years.

Diverse Application Scenarios and Operational Advantages

The versatility of the YDQ-2500 Hydraulic Conductor Fixture makes it an indispensable tool across numerous industrial sectors requiring precise material testing. In the power transmission sector, it is crucial for evaluating overhead line conductors (e.g., ACSR, AAAC, AAC) for their tensile strength, ensuring they can withstand wind loads, ice accumulation, and long-term tension. For underground cables, it assesses the integrity of the conductor core, vital for preventing failures in high-voltage distribution networks. Within the construction industry, it's employed for testing high-strength steel ropes and cables used in bridges, elevators, and structural reinforcements, where safety margins are extremely tight.

Beyond traditional applications, the YDQ-2500 Hydraulic Conductor Fixture finds utility in specialized fields such as marine engineering for testing mooring lines and umbilical cables, and in aerospace for evaluating high-performance wires. Its primary advantage lies in its hydraulic gripping mechanism, which provides an exceptionally uniform and powerful clamping force, preventing slippage that often plagues mechanical grips, particularly with large or slick conductors. This hydraulic advantage ensures that the test force is accurately transmitted to the specimen, yielding precise and reproducible results, which is crucial for material certification and research. Furthermore, its robust construction and high-grade materials guarantee a long operational lifespan and minimal maintenance, translating into a lower total cost of ownership.

Comparative Analysis: Why Choose Our YDQ-2500

When selecting a hydraulic conductor fixture, discerning buyers prioritize reliability, precision, and long-term value. While several manufacturers offer similar solutions, our YDQ-2500 Hydraulic Conductor Fixture distinguishes itself through a combination of superior material selection, advanced manufacturing precision, and comprehensive customer support, backed by over two decades of industry experience. Unlike some competitors who might compromise on material quality to reduce costs, we utilize aerospace-grade alloy steels and precision-machined hydraulic components, ensuring unmatched durability and minimal wear even under continuous high-load operations. Our fixtures undergo rigorous ISO 9001 certified quality management processes, including multi-stage NDT and load calibration, exceeding the typical checks performed by others.

A common challenge with lesser fixtures is inconsistent gripping pressure, leading to specimen slippage or premature failure outside the gauge length. Our YDQ-2500 Hydraulic Conductor Fixture addresses this with a proprietary jaw design and a finely tuned hydraulic control system, delivering uniform clamping force across the entire contact area, a critical differentiator for accurate tensile testing. Furthermore, our commitment extends beyond product delivery, offering extensive post-sales support including on-site training, swift spare parts availability, and a dedicated technical support team, factors often overlooked by other suppliers. Our service tenure of over 20 years in the testing equipment industry, coupled with numerous successful installations for major utility companies and cable manufacturers worldwide, stands as a testament to our authoritativeness and trustworthiness.

Customization Capabilities and Comprehensive Support

Recognizing that no two testing environments are identical, we offer extensive customization options for the YDQ-2500 Hydraulic Conductor Fixture. This includes tailored jaw designs for unique conductor geometries, extended clamping lengths for specialized tests, and integration with existing universal testing machines (UTMs) or data acquisition systems. Our engineering team collaborates closely with clients to develop solutions that precisely meet their operational challenges, whether it's for very large diameter cables, highly delicate composite conductors, or specific industry standards like ASTM B232 for ACSR conductors or IEC 60888 for aluminum alloy conductors. This bespoke approach ensures optimal performance and efficiency, maximizing the return on investment for our partners.

Our commitment to client success is underpinned by a robust support framework. From the initial consultation and design phase to installation, commissioning, and ongoing maintenance, our experts provide end-to-end assistance. We offer comprehensive training programs for operators and maintenance personnel, ensuring they are fully proficient in utilizing the YDQ-2500 Hydraulic Conductor Fixture to its full potential. Our standard warranty periods are competitive, and we also provide extended service contracts and preventative maintenance schedules to minimize downtime. Regarding delivery, our streamlined logistics ensure efficient dispatch and installation, with clear communication on lead times from order placement to operational readiness, typically ranging from 8-12 weeks depending on customization requirements.

Real-World Application Cases and Success Stories

The efficacy of the YDQ-2500 Hydraulic Conductor Fixture is best demonstrated through its successful deployment in various demanding environments globally. For instance, a leading European power utility adopted the YDQ-2500 for routine tensile testing of high-voltage transmission line conductors, reporting a 30% reduction in test cycle time due to the fixture's efficient hydraulic clamping and release mechanism, alongside a significant improvement in data consistency, leading to more reliable material procurement decisions. In another instance, a major Asian cable manufacturer utilized the fixture for R&D on new carbon fiber composite conductors, where its precise and uniform gripping was crucial for accurately measuring the material's complex stress-strain behavior without introducing localized damage.

A recent case involved a North American steel wire rope manufacturer, who struggled with slippage when testing large diameter steel ropes for mining applications using traditional mechanical grips. Post-installation of the YDQ-2500 Hydraulic Conductor Fixture, they achieved consistently accurate tensile strength measurements, significantly reducing material waste from failed tests and enhancing product quality assurance. These examples underscore the fixture's capability to deliver tangible benefits—improving efficiency, enabling advanced material research, and boosting overall product reliability across diverse industries. The positive feedback from these and many other satisfied clients reinforces our commitment to delivering superior testing solutions that empower industries to achieve their quality and safety objectives.

Frequently Asked Questions (FAQ)

- Q: What is the maximum conductor size the YDQ-2500 can accommodate?

A: The standard YDQ-2500 Hydraulic Conductor Fixture can accommodate conductors with diameters ranging from Ø 10 mm to Ø 100 mm. Custom jaw designs are available for specific requirements outside this range or for non-circular conductor profiles. - Q: Is the YDQ-2500 compatible with universal testing machines from other manufacturers?

A: Yes, the YDQ-2500 Hydraulic Conductor Fixture is designed for broad compatibility. We can provide custom adapters and connection interfaces to seamlessly integrate it with most major brands of universal testing machines, ensuring smooth operation and data synchronization. - Q: What kind of maintenance does the YDQ-2500 require?

A: Regular maintenance for the YDQ-2500 Hydraulic Conductor Fixture primarily involves checking hydraulic fluid levels, inspecting seals for wear, and cleaning jaw surfaces. A detailed maintenance schedule is provided in the user manual, and our service team is available for annual inspections and preventative maintenance. - Q: What is the expected delivery timeframe for a YDQ-2500 fixture?

A: For standard configurations, the delivery timeframe typically ranges from 8 to 12 weeks from order confirmation. Custom orders may require additional time for design and manufacturing, which will be clearly communicated during the quotation process.

Delivery, Warranty, and Customer Support

We understand that prompt delivery and reliable post-sales support are critical for our B2B clients. Upon order confirmation, each YDQ-2500 Hydraulic Conductor Fixture unit undergoes a final quality inspection and meticulous packaging to ensure safe transit. Our logistics team coordinates with reputable freight partners to ensure timely and secure delivery to your facility worldwide. We provide comprehensive documentation including installation guides, user manuals, and calibration certificates. Our standard warranty covers manufacturing defects and material failures for a period of 12 months from installation or 18 months from shipment, whichever comes first, demonstrating our confidence in the product's quality and durability.

Beyond the warranty period, we offer flexible service agreements, including extended warranties, preventative maintenance contracts, and priority technical support. Our dedicated customer support team and network of certified service engineers are available for remote troubleshooting, on-site assistance, and calibration services, ensuring minimal downtime and sustained performance of your YDQ-2500 Hydraulic Conductor Fixture. We maintain a comprehensive inventory of genuine spare parts, guaranteeing their availability for immediate dispatch. Our commitment to excellence extends throughout the entire product lifecycle, providing you with peace of mind and maximizing your operational efficiency.

References

- ASTM International. (2020). ASTM E4-17: Standard Practices for Force Verification of Testing Machines.

- International Organization for Standardization. (2018). ISO 7500-1: Metallic materials — Calibration and verification of static uniaxial testing machines — Part 1: Tension/compression testing machines — Calibration and verification of the force-measuring system.

- Institute of Electrical and Electronics Engineers. (2021). IEEE Std 738: IEEE Standard for Calculating the Current-Temperature Relationship of Bare Overhead Conductors.

- Electric Power Research Institute (EPRI). (2019). Report on Advanced Conductor Technologies for Grid Modernization.

- World Energy Council. (2022). World Energy Issues Monitor: Grid Resilience and Modernization.

Unlocking Precision and Durability: The YDQ-2500 Hydraulic Conductor Fixture in Modern Testing

In the rigorous world of material science and engineering, particularly within the wire and cable industry, the integrity of conductor materials is paramount. Ensuring their reliability under extreme stress and various environmental conditions is not merely a quality control measure but a critical safety prerequisite. This necessitates specialized testing equipment capable of delivering unparalleled precision and consistent performance. The YDQ-2500 Hydraulic Conductor Fixture stands as a benchmark in this domain, designed to securely hold and test conductors with hydraulic force, replicating real-world operational stresses. Its advanced design addresses the evolving demands of high-strength conductor testing, minimizing slippage and maximizing data accuracy, which are crucial for evaluating new alloy compositions, optimizing existing designs, and ensuring compliance with stringent international standards like ASTM and IEC. This fixture is a cornerstone for R&D departments and quality assurance laboratories striving for excellence in conductor analysis.

Industry Trends and Technological Imperatives

The global energy transmission and distribution landscape is undergoing rapid transformation, driven by the increasing integration of renewable energy sources and the expansion of smart grids. This paradigm shift demands conductors with enhanced mechanical strength, improved fatigue resistance, and superior thermal performance. Consequently, the demand for advanced testing methodologies and equipment, such as the YDQ-2500 Hydraulic Conductor Fixture, has surged. Industry trends indicate a lean towards automated testing systems, non-destructive evaluation techniques, and the use of digital twins for predictive maintenance, all of which rely on highly accurate initial material characterization. Furthermore, environmental regulations are pushing for lighter, more efficient materials, increasing the complexity and precision required in testing. Manufacturers are continuously innovating to meet these challenges, with a focus on enhancing fixture longevity, reducing maintenance, and ensuring compatibility with a wide range of conductor types, from conventional copper and aluminum to advanced composite materials.

The shift towards higher voltage transmission and smarter grid infrastructure has placed unprecedented demands on the mechanical robustness of electrical conductors. This necessitates testing equipment that can apply and sustain precise tensile loads, ensuring that conductors can withstand environmental stressors, installation strains, and long-term operational fatigue. The YDQ-2500 Hydraulic Conductor Fixture is at the forefront of this evolution, offering the precision and stability required for critical tests like ultimate tensile strength (UTS) and elongation, which are fundamental to assessing conductor reliability. The fixture's design also incorporates features that cater to the testing of new-generation conductors, including those with intricate stranding patterns or composite cores, reflecting the industry's move towards materials that balance conductivity with exceptional mechanical properties.

Key Technical Specifications and Performance Parameters

Understanding the precise capabilities of the YDQ-2500 Hydraulic Conductor Fixture is essential for optimizing testing protocols and ensuring accurate data acquisition. This fixture is engineered to handle substantial tensile forces, making it suitable for a wide array of conductor types and sizes. Below is a detailed table outlining its core technical parameters, derived from extensive engineering specifications and performance benchmarks, which underscore its robust design and high-precision capabilities. These specifications are critical for laboratories and manufacturing facilities in determining the fixture's suitability for their specific testing requirements, ranging from routine quality control to advanced material research and development.

| Parameter | Specification | Notes |

|---|---|---|

| Max. Test Load Capacity | 2500 kN (250 Tons) | Designed for heavy-duty conductor testing. |

| Clamping Method | Hydraulic Gripping | Ensures secure, non-slip hold. |

| Applicable Conductor Diameter | Ø 10 mm - Ø 100 mm (customizable) | Versatile range for various conductor types. |

| Jaw Opening/Closing Speed | Adjustable, typically 0.5-2 mm/s | Controlled operation for safety and precision. |

| Hydraulic System Pressure | Up to 25 MPa | High-pressure system for robust clamping. |

| Operating Temperature Range | -10°C to +50°C | Suitable for standard lab environments. |

| Material Construction | High-strength alloy steel (e.g., 42CrMo) | Ensures durability and long service life. |

| Weight (Approx.) | ~ 800 kg (per set of jaws) | Indicates robust, heavy-duty construction. |

| Typical Service Life | 10+ Years (with proper maintenance) | High return on investment. |

The hydraulic gripping mechanism of the YDQ-2500 Hydraulic Conductor Fixture is designed for unparalleled clamping force, evenly distributing pressure across the conductor's surface. This prevents localized deformation or premature failure at the gripping point, ensuring that the test results accurately reflect the material properties of the conductor itself, not an artifact of the clamping. The versatility in handling various conductor diameters is achieved through interchangeable jaw inserts, which can be custom-designed for specific conductor profiles, including those with non-circular cross-sections. This adaptability makes the YDQ-2500 a cornerstone for laboratories dealing with a diverse range of cable and wire products, from overhead transmission lines to specialized industrial cables.

Precision Manufacturing and Rigorous Quality Assurance

The manufacturing of the YDQ-2500 Hydraulic Conductor Fixture is a testament to precision engineering, adhering to the highest industry standards to ensure its reliability and longevity. The process begins with the selection of premium alloy steels, such as 42CrMo, renowned for its exceptional strength, toughness, and wear resistance, crucial for components under immense stress. Key components like the main body and hydraulic cylinders undergo advanced forging processes to refine their grain structure, enhancing mechanical properties and eliminating internal defects. This is followed by meticulous CNC machining, achieving micron-level tolerances for critical interfaces, ensuring smooth hydraulic operation and perfect alignment, which is paramount for preventing slippage during high-load tests.

Post-machining, components of the YDQ-2500 Hydraulic Conductor Fixture undergo specialized heat treatments, including quenching and tempering, to achieve optimal hardness and ductility, preventing premature wear and fatigue under repetitive loading cycles. Surface treatments like nitriding or chrome plating are then applied to enhance corrosion resistance and reduce friction, extending the fixture's operational life, particularly in challenging industrial environments. Every single component, from the smallest seal to the largest structural element, is subjected to stringent quality control checks. This includes non-destructive testing (NDT) methods like ultrasonic and magnetic particle inspection to detect any subsurface flaws, along with precise dimensional verification using CMM (Coordinate Measuring Machine) technology.

Before final assembly, each hydraulic circuit is pressure-tested far beyond its operational limits to ensure leak-proof performance and structural integrity. The assembled YDQ-2500 Hydraulic Conductor Fixture then undergoes a comprehensive calibration process, verified against international standards such as ISO 7500-1 and ASTM E4, guaranteeing its force accuracy and repeatability. This rigorous manufacturing and inspection regimen ensures that the fixture not only meets but often exceeds the demanding requirements of industries like petrochemicals, metallurgy, and water supply and drainage, where equipment reliability and safety are non-negotiable. Its robust construction and anti-corrosion treatments also contribute to significant energy savings by minimizing operational downtime and replacement costs over a typical service life exceeding 10 years.

Diverse Application Scenarios and Operational Advantages

The versatility of the YDQ-2500 Hydraulic Conductor Fixture makes it an indispensable tool across numerous industrial sectors requiring precise material testing. In the power transmission sector, it is crucial for evaluating overhead line conductors (e.g., ACSR, AAAC, AAC) for their tensile strength, ensuring they can withstand wind loads, ice accumulation, and long-term tension. For underground cables, it assesses the integrity of the conductor core, vital for preventing failures in high-voltage distribution networks. Within the construction industry, it's employed for testing high-strength steel ropes and cables used in bridges, elevators, and structural reinforcements, where safety margins are extremely tight.

Beyond traditional applications, the YDQ-2500 Hydraulic Conductor Fixture finds utility in specialized fields such as marine engineering for testing mooring lines and umbilical cables, and in aerospace for evaluating high-performance wires. Its primary advantage lies in its hydraulic gripping mechanism, which provides an exceptionally uniform and powerful clamping force, preventing slippage that often plagues mechanical grips, particularly with large or slick conductors. This hydraulic advantage ensures that the test force is accurately transmitted to the specimen, yielding precise and reproducible results, which is crucial for material certification and research. Furthermore, its robust construction and high-grade materials guarantee a long operational lifespan and minimal maintenance, translating into a lower total cost of ownership.

Comparative Analysis: Why Choose Our YDQ-2500

When selecting a hydraulic conductor fixture, discerning buyers prioritize reliability, precision, and long-term value. While several manufacturers offer similar solutions, our YDQ-2500 Hydraulic Conductor Fixture distinguishes itself through a combination of superior material selection, advanced manufacturing precision, and comprehensive customer support, backed by over two decades of industry experience. Unlike some competitors who might compromise on material quality to reduce costs, we utilize aerospace-grade alloy steels and precision-machined hydraulic components, ensuring unmatched durability and minimal wear even under continuous high-load operations. Our fixtures undergo rigorous ISO 9001 certified quality management processes, including multi-stage NDT and load calibration, exceeding the typical checks performed by others.

A common challenge with lesser fixtures is inconsistent gripping pressure, leading to specimen slippage or premature failure outside the gauge length. Our YDQ-2500 Hydraulic Conductor Fixture addresses this with a proprietary jaw design and a finely tuned hydraulic control system, delivering uniform clamping force across the entire contact area, a critical differentiator for accurate tensile testing. Furthermore, our commitment extends beyond product delivery, offering extensive post-sales support including on-site training, swift spare parts availability, and a dedicated technical support team, factors often overlooked by other suppliers. Our service tenure of over 20 years in the testing equipment industry, coupled with numerous successful installations for major utility companies and cable manufacturers worldwide, stands as a testament to our authoritativeness and trustworthiness.

Customization Capabilities and Comprehensive Support

Recognizing that no two testing environments are identical, we offer extensive customization options for the YDQ-2500 Hydraulic Conductor Fixture. This includes tailored jaw designs for unique conductor geometries, extended clamping lengths for specialized tests, and integration with existing universal testing machines (UTMs) or data acquisition systems. Our engineering team collaborates closely with clients to develop solutions that precisely meet their operational challenges, whether it's for very large diameter cables, highly delicate composite conductors, or specific industry standards like ASTM B232 for ACSR conductors or IEC 60888 for aluminum alloy conductors. This bespoke approach ensures optimal performance and efficiency, maximizing the return on investment for our partners.

Our commitment to client success is underpinned by a robust support framework. From the initial consultation and design phase to installation, commissioning, and ongoing maintenance, our experts provide end-to-end assistance. We offer comprehensive training programs for operators and maintenance personnel, ensuring they are fully proficient in utilizing the YDQ-2500 Hydraulic Conductor Fixture to its full potential. Our standard warranty periods are competitive, and we also provide extended service contracts and preventative maintenance schedules to minimize downtime. Regarding delivery, our streamlined logistics ensure efficient dispatch and installation, with clear communication on lead times from order placement to operational readiness, typically ranging from 8-12 weeks depending on customization requirements.

Real-World Application Cases and Success Stories

The efficacy of the YDQ-2500 Hydraulic Conductor Fixture is best demonstrated through its successful deployment in various demanding environments globally. For instance, a leading European power utility adopted the YDQ-2500 for routine tensile testing of high-voltage transmission line conductors, reporting a 30% reduction in test cycle time due to the fixture's efficient hydraulic clamping and release mechanism, alongside a significant improvement in data consistency, leading to more reliable material procurement decisions. In another instance, a major Asian cable manufacturer utilized the fixture for R&D on new carbon fiber composite conductors, where its precise and uniform gripping was crucial for accurately measuring the material's complex stress-strain behavior without introducing localized damage.

A recent case involved a North American steel wire rope manufacturer, who struggled with slippage when testing large diameter steel ropes for mining applications using traditional mechanical grips. Post-installation of the YDQ-2500 Hydraulic Conductor Fixture, they achieved consistently accurate tensile strength measurements, significantly reducing material waste from failed tests and enhancing product quality assurance. These examples underscore the fixture's capability to deliver tangible benefits—improving efficiency, enabling advanced material research, and boosting overall product reliability across diverse industries. The positive feedback from these and many other satisfied clients reinforces our commitment to delivering superior testing solutions that empower industries to achieve their quality and safety objectives.

Frequently Asked Questions (FAQ)

- Q: What is the maximum conductor size the YDQ-2500 can accommodate?

A: The standard YDQ-2500 Hydraulic Conductor Fixture can accommodate conductors with diameters ranging from Ø 10 mm to Ø 100 mm. Custom jaw designs are available for specific requirements outside this range or for non-circular conductor profiles. - Q: Is the YDQ-2500 compatible with universal testing machines from other manufacturers?

A: Yes, the YDQ-2500 Hydraulic Conductor Fixture is designed for broad compatibility. We can provide custom adapters and connection interfaces to seamlessly integrate it with most major brands of universal testing machines, ensuring smooth operation and data synchronization. - Q: What kind of maintenance does the YDQ-2500 require?

A: Regular maintenance for the YDQ-2500 Hydraulic Conductor Fixture primarily involves checking hydraulic fluid levels, inspecting seals for wear, and cleaning jaw surfaces. A detailed maintenance schedule is provided in the user manual, and our service team is available for annual inspections and preventative maintenance. - Q: What is the expected delivery timeframe for a YDQ-2500 fixture?

A: For standard configurations, the delivery timeframe typically ranges from 8 to 12 weeks from order confirmation. Custom orders may require additional time for design and manufacturing, which will be clearly communicated during the quotation process.

Delivery, Warranty, and Customer Support

We understand that prompt delivery and reliable post-sales support are critical for our B2B clients. Upon order confirmation, each YDQ-2500 Hydraulic Conductor Fixture unit undergoes a final quality inspection and meticulous packaging to ensure safe transit. Our logistics team coordinates with reputable freight partners to ensure timely and secure delivery to your facility worldwide. We provide comprehensive documentation including installation guides, user manuals, and calibration certificates. Our standard warranty covers manufacturing defects and material failures for a period of 12 months from installation or 18 months from shipment, whichever comes first, demonstrating our confidence in the product's quality and durability.

Beyond the warranty period, we offer flexible service agreements, including extended warranties, preventative maintenance contracts, and priority technical support. Our dedicated customer support team and network of certified service engineers are available for remote troubleshooting, on-site assistance, and calibration services, ensuring minimal downtime and sustained performance of your YDQ-2500 Hydraulic Conductor Fixture. We maintain a comprehensive inventory of genuine spare parts, guaranteeing their availability for immediate dispatch. Our commitment to excellence extends throughout the entire product lifecycle, providing you with peace of mind and maximizing your operational efficiency.

References

- ASTM International. (2020). ASTM E4-17: Standard Practices for Force Verification of Testing Machines.

- International Organization for Standardization. (2018). ISO 7500-1: Metallic materials — Calibration and verification of static uniaxial testing machines — Part 1: Tension/compression testing machines — Calibration and verification of the force-measuring system.

- Institute of Electrical and Electronics Engineers. (2021). IEEE Std 738: IEEE Standard for Calculating the Current-Temperature Relationship of Bare Overhead Conductors.

- Electric Power Research Institute (EPRI). (2019). Report on Advanced Conductor Technologies for Grid Modernization.

- World Energy Council. (2022). World Energy Issues Monitor: Grid Resilience and Modernization.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy