electrical insulation resistance tester suppliers

Understanding Electrical Insulation Resistance Testers and Their Suppliers

In the realm of electrical engineering and maintenance, ensuring the safety and functionality of electrical systems is paramount. One crucial aspect of this safety is the measurement of insulation resistance, which helps evaluate the integrity of electrical insulation. This is where electrical insulation resistance testers come into play, making it essential to understand their significance, operation, and the suppliers that provide high-quality devices.

What is an Electrical Insulation Resistance Tester?

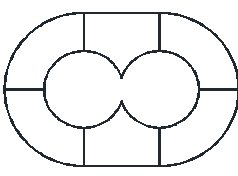

An electrical insulation resistance tester is an instrument used to assess the insulation resistance of electrical equipment and wiring. By applying a specified voltage to the insulation and measuring the current that flows through it, these testers provide insights into the insulation’s effectiveness. Commonly, a higher resistance reading indicates better insulation conditions, whereas low readings may signify deterioration or damage, which could lead to potential hazards like electrical leakage or short circuits.

How Do Insulation Resistance Testers Work?

Insulation resistance testers work by generating a high voltage—typically between 250V and 1000V—across the insulation barrier. The apparatus measures the current that flows through the insulation under this voltage, calculating the insulation resistance using Ohm's law \( R = V / I \), where \( R \) is resistance, \( V \) is voltage, and \( I \) is current.

Most modern testers come equipped with various features, such as multiple testing voltages, automatic polarity switching, and data logging capabilities. Some devices also offer insulation diagnostic functions that can indicate the condition of the insulation material rather than just a pass/fail reading.

The Importance of Insulation Resistance Testing

Regular insulation testing is vital for several reasons

1. Safety Faulty insulation can lead to electrical shocks, fires, and other dangerous situations. Regular testing helps identify potential risks before they lead to accidents.

electrical insulation resistance tester suppliers

2. Equipment Longevity By maintaining good insulation, operators can extend the life of electrical equipment and minimize unexpected downtimes or costly repairs.

3. Compliance with Standards Many industries have strict regulations regarding equipment safety. Regular insulation testing ensures compliance with standards set by organizations such as the Occupational Safety and Health Administration (OSHA) or the National Electrical Code (NEC).

Selecting the Right Supplier

When considering insulation resistance testers, selecting a reputable supplier is critical. A good supplier will not only offer high-quality, reliable equipment but also provide support services like calibration, maintenance, and training for effective usage.

1. Quality and Variety Look for suppliers that offer a wide range of testers, from basic models for routine checks to advanced diagnostic tools for detailed analysis. Brands renowned for their quality, such as Fluke, Megger, and Seaward, are often a safe bet.

2. Technical Support and Training A reliable supplier should provide comprehensive customer support and training to help users understand how to operate the testers properly and interpret the results.

3. Compliance and Certification Ensure that the devices meet relevant safety standards and regulations. A good supplier will resist supply equipment that complies with international standards.

4. Customer Reviews and Reputation Research customer testimonials and the supplier’s reputation in the market. Suppliers with consistently positive feedback often reflect their ability to provide both quality products and excellent service.

Conclusion

Electrical insulation resistance testers play a crucial role in ensuring the safety and reliability of electrical systems. By understanding how these testers work and selecting the right supplier, organizations can effectively manage and mitigate electrical risks. Always prioritize quality, support, and compliance when sourcing insulation resistance testers to safeguard both personnel and equipment, ultimately helping to create a safer and more efficient working environment.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy