Custom Fire Resistance Testing Equipment for Enhanced Safety and Performance Evaluation

Custom Fire Resistance Tester Ensuring Safety Through Innovation

In today's world, where safety standards are continually evolving, the importance of fire resistance testing cannot be overstated. Fire-related incidents can result in catastrophic damage, loss of life, and significant financial burdens. To mitigate these risks, customized fire resistance testers have emerged as indispensable tools in various industries. This article explores the significance, features, and applications of custom fire resistance testers, highlighting their role in enhancing safety protocols.

The Importance of Fire Resistance Testing

Fire resistance testing is a crucial component of building safety and material performance evaluation. It helps determine how materials and structures respond to fire exposure, assessing their ability to withstand heat, smoke, and flames. Testing ensures that materials comply with regulatory standards, providing reassurance to manufacturers, builders, and consumers alike.

The consequences of inadequate fire resistance can be dire. From residential buildings to commercial establishments, the potential for fire to compromise the integrity of a structure is omnipresent. Thus, bespoke fire resistance testing solutions are essential for tailoring assessments to meet specific material requirements and environmental conditions.

Features of Custom Fire Resistance Testers

Custom fire resistance testers are designed with flexibility and precision in mind. Here are some of the notable features that make these testers effective

1. Versatility Custom testers can be configured to evaluate various materials, including textiles, woods, composites, and metals. Depending on the industry, testers can simulate different fire scenarios to provide a comprehensive assessment.

2. Temperature Control Advanced technology allows for precise temperature regulation during testing. Custom testers can replicate real-world fire events, subjecting materials to targeted heat levels for specific durations.

3. Real-time Monitoring Many modern fire resistance testers are equipped with sensors and data logging systems. This allows for real-time monitoring of the test environment and automatic recording of critical data, such as temperature fluctuations and material behavior under stress.

custom fire resistance tester

4. Compliance with Standards Custom testers can be designed to meet specific national and international fire safety standards, such as ASTM, ISO, and UL. This ensures that testing outcomes are valid and recognized across different markets.

5. User-friendly Interface Custom testers often feature intuitive interfaces to facilitate operation and data interpretation. Operators can easily navigate through testing parameters, making the entire process more efficient.

Applications Across Industries

The applications of custom fire resistance testers are extensive and varied. Here are a few sectors that benefit significantly from these advanced testing solutions

- Construction and Architecture In the construction industry, fire resistance testing is vital for selecting materials that will perform under fire exposure. Custom testers help architects and builders ensure compliance with safety regulations while maintaining design aesthetics.

- Aerospace and Automotive In the aerospace and automotive industries, materials are regularly tested for fire resistance to meet strict safety standards. Custom testers provide insights into how materials behave in case of an emergency, ensuring passenger safety during flight or driving.

- Textile Industry Upholstery and clothing manufacturers utilize custom fire resistance testers to assess the flammability of fabrics. Testing ensures that textiles meet safety requirements, particularly for products used in public spaces, where fire safety is critical.

- Electronics and Electrical Devices The electronics industry also adopts fire resistance testing to evaluate the safety of components and devices. Custom testers assess the potential for ignition and the resulting fire spread from electrical failures.

Conclusion

Custom fire resistance testers play a pivotal role in safeguarding lives and properties from the devastating impacts of fire. By providing tailored testing solutions, industries can ensure compliance with safety standards while fostering innovation in material development. As technology advances and safety regulations become more stringent, the demand for custom fire resistance testing will undoubtedly continue to grow. Investing in these testing capabilities is not just a regulatory obligation; it is a commitment to the safety and well-being of society as a whole.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

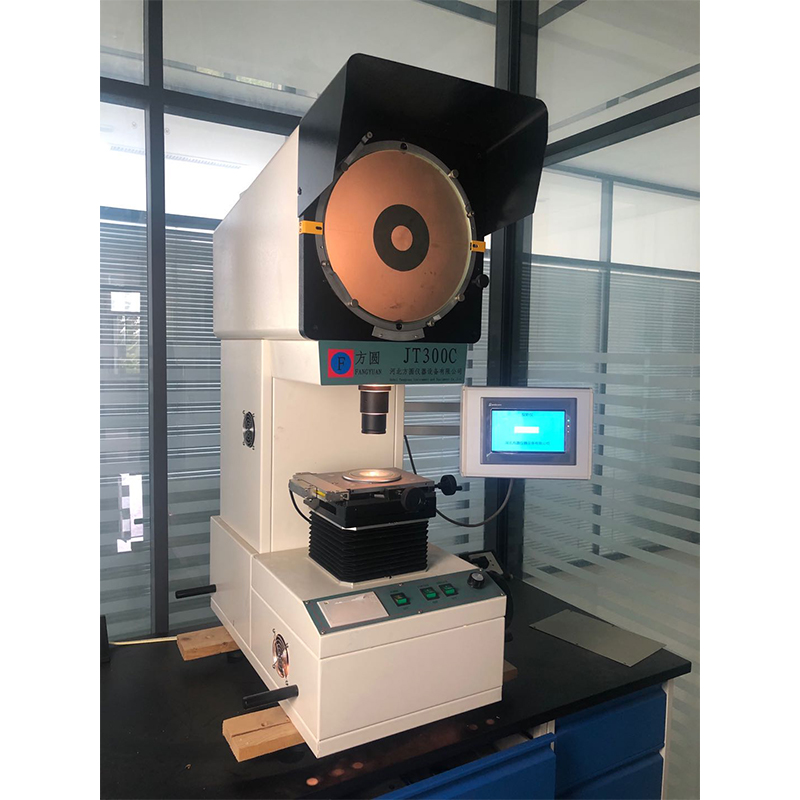

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy