feb . 02, 2025 01:27

Back to list

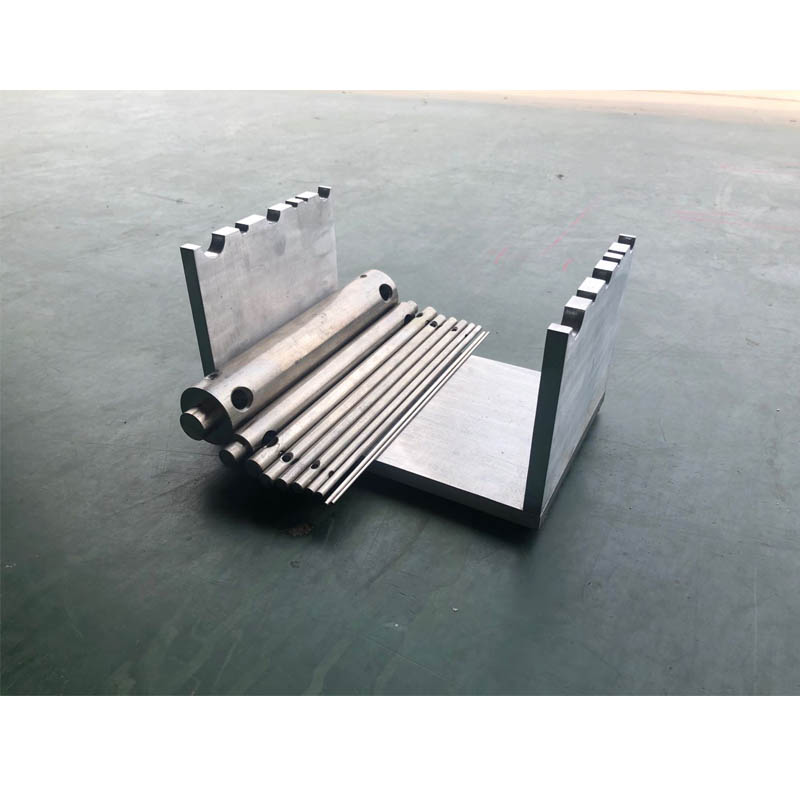

custom tensile tester grips

Understanding the intricacies of customizing tensile tester grips is paramount for industries that rely on precision testing. These specific components ensure that materials are evaluated accurately, offering the insights needed to refine product quality.

Furthermore, custom grips contribute to improved lab efficiency. By reducing the time spent in setup and adjustment, they allow testing personnel to focus on analyzing results rather than troubleshooting equipment issues. Streamlined operation ensures a higher throughput, making it economically viable for labs with ongoing high-volume testing requirements. The credibility of test results is also enhanced through the use of custom grips. Accurate test data is foundational for research and development, and in some cases, it might even influence regulatory compliance. By ensuring consistency, custom grips provide a foundation for building trust with stakeholders, who rely on the precise performance metrics provided by tensile testing. Moreover, engaging with a trusted manufacturer for custom grips ensures that the design meets all technical and safety standards. It is crucial to collaborate with companies that not only have technical expertise but also possess authoritative knowledge of specific industry requirements. Such partnerships often deliver innovative grip solutions tailored to optimize test performance. While the investment in custom tensile tester grips might seem higher initially compared to off-the-shelf solutions, the long-term benefits are significant. By delivering precise data, enhancing testing efficiency, and supporting the development of high-quality products, these custom grips often justify their cost through the value they add. In conclusion, while off-the-shelf tensile grips can serve basic testing needs, custom tensile tester grips provide unparalleled advantages in performance, precision, and reliability. For industries committed to maintaining stringent quality standards and pushing the boundaries of innovation, the adoption of bespoke grips is not merely an option but a strategic imperative.

Furthermore, custom grips contribute to improved lab efficiency. By reducing the time spent in setup and adjustment, they allow testing personnel to focus on analyzing results rather than troubleshooting equipment issues. Streamlined operation ensures a higher throughput, making it economically viable for labs with ongoing high-volume testing requirements. The credibility of test results is also enhanced through the use of custom grips. Accurate test data is foundational for research and development, and in some cases, it might even influence regulatory compliance. By ensuring consistency, custom grips provide a foundation for building trust with stakeholders, who rely on the precise performance metrics provided by tensile testing. Moreover, engaging with a trusted manufacturer for custom grips ensures that the design meets all technical and safety standards. It is crucial to collaborate with companies that not only have technical expertise but also possess authoritative knowledge of specific industry requirements. Such partnerships often deliver innovative grip solutions tailored to optimize test performance. While the investment in custom tensile tester grips might seem higher initially compared to off-the-shelf solutions, the long-term benefits are significant. By delivering precise data, enhancing testing efficiency, and supporting the development of high-quality products, these custom grips often justify their cost through the value they add. In conclusion, while off-the-shelf tensile grips can serve basic testing needs, custom tensile tester grips provide unparalleled advantages in performance, precision, and reliability. For industries committed to maintaining stringent quality standards and pushing the boundaries of innovation, the adoption of bespoke grips is not merely an option but a strategic imperative.

Next:

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy