Exporter of Electronic Universal Tensile Testing Machines for Industrial Applications

Exploring the Role of Electronic Universal Tensile Testing Machines in Material Testing

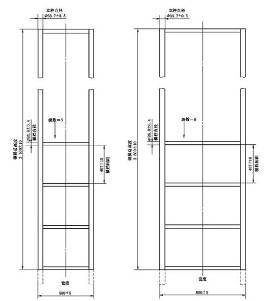

In the realm of material testing, the electronic universal tensile testing machine stands out as a crucial instrument designed to assess the mechanical properties of various materials. From metals to plastics and composites, these machines play a vital role in determining strength, elasticity, ductility, and more. As industries and research institutions strive for quality and reliability, the demand for electronic universal tensile testing machines is on the rise globally, leading to a burgeoning market for exporters.

The electronic universal tensile testing machine operates by applying a uniaxial tensile force to a specimen until failure occurs. The machine is equipped with sophisticated digital controls and precise load cells that ensure accurate results. Measurements of force and elongation are taken continuously during the test, providing a comprehensive dataset that can be analyzed to determine key material properties.

One of the primary advantages of electronic universal tensile testing machines is their automation and ease of use. Equipped with advanced software, these machines can be programmed to conduct a wide range of tests, including tensile, compression, flexural, and shear tests. The automation allows for high throughput testing, which is essential for large-scale manufacturing processes. Operators can easily input parameters and monitor tests remotely, increasing efficiency and reducing the likelihood of human error.

The global market for electronic universal tensile testing machines is driven by several factors. Increasing investments in industrial manufacturing, quality control measures, and research and development are at the forefront. Industries such as automotive, aerospace, construction, and electronics require rigorous testing to ensure that materials meet stringent quality standards. Consequently, the need for reliable testing equipment has surged, prompting many manufacturers to become exporters of these essential machines.

electronic universal tensile testing machine exporter

Exporting electronic universal tensile testing machines is not just a business opportunity; it also aids in advancing global technology standards. Countries that may not have the latest testing technologies can benefit from imports, fostering innovation and improving their materials testing capabilities. This technological transfer can lead to enhanced product quality and safety, ultimately benefiting consumers worldwide.

Moreover, as environmental concerns grow, there is a shift towards sustainable materials and practices. The need to evaluate the mechanical properties of eco-friendly materials, such as bioplastics and composites derived from renewable sources, is more pressing than ever. Electronic universal tensile testing machines are evolving to accommodate these new materials, allowing industries to innovate responsibly while ensuring product integrity.

However, as with any equipment, there are challenges faced by exporters of electronic universal tensile testing machines. Competition is fierce in the global market, with numerous manufacturers vying for attention. Establishing a robust brand identity and ensuring compliance with international quality standards are imperative for success. Additionally, providing exceptional customer service, including technical support and maintenance, can set apart exporters in this competitive landscape.

In summary, electronic universal tensile testing machines play a crucial role in material testing across various industries. Their automated capabilities, precision, and versatile applications make them indispensable tools for quality control and research. As the demand for these machines continues to grow, especially in emerging markets, exporters have a unique opportunity to contribute to global advancements in materials testing technology. By meeting the challenges of this competitive industry, they can help elevate product standards and, ultimately, consumer safety and satisfaction. With ongoing innovations and a focus on sustainability, the future of electronic universal tensile testing machines looks promising, paving the way for a new era in material science and engineering.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy