Reliable Aging Test Chamber Solutions for Accurate Material Durability Assessment and Quality Control Procedures

Understanding the Importance of Aging Test Chambers in Material Reliability Testing

In the realm of materials science and product development, the integrity and performance of materials over time are crucial. Aging test chambers play a vital role in assessing the longevity of materials and components by simulating the effects of aging in a controlled environment. This article explores the significance of aging test chambers, their functioning, and the factors that distinguish manufacturers in this specialized field.

What is an Aging Test Chamber?

An aging test chamber is a specialized equipment designed to replicate environmental conditions that materials might encounter over their lifecycle. These chambers can simulate various aging processes, including thermal aging, humidity, UV exposure, and mechanical stress. By recreating these conditions, manufacturers can predict how materials will behave over time, allowing for more robust product design and quality assurance.

Importance of Aging Tests

The importance of aging tests cannot be overstated, especially in sectors such as electronics, automotive, aerospace, and construction. These industries rely heavily on materials that must perform reliably under various conditions. For instance, automotive components must withstand extreme temperatures and moisture, while electronic devices are often exposed to humidity and heat. Aging tests help identify potential failures before products reach the market, saving manufacturers time and resources while ensuring consumer safety.

Features of Quality Aging Test Chambers

When assessing aging test chamber manufacturers, several key features are important to consider

1. Temperature Control The chamber should provide precise and stable temperature control to simulate the desired aging conditions accurately. Advanced manufacturers use sophisticated sensors and controllers to maintain consistency.

2. Humidity Control The ability to control humidity levels is crucial for testing materials that are sensitive to moisture. High-quality chambers can mimic a range of humidity conditions, facilitating a better understanding of how materials degrade over time.

3. UV and Light Exposure For materials that are prone to photodegradation, such as plastics and coatings, UV exposure is critical. An effective aging test chamber will incorporate UV lights to replicate sunlight exposure and evaluate how materials hold up under these conditions.

aging test chamber manufacturer

4. Data Logging and Monitoring Modern aging test chambers come equipped with advanced data logging systems that track temperature, humidity, and other critical parameters throughout the testing process. This data is invaluable for analysis and for ensuring compliance with industry standards.

5. Customization Options Different materials and products require different testing conditions. A good manufacturer will offer customization options to tailor the aging tests to specific industry needs.

Choosing the Right Manufacturer

Selecting the right aging test chamber manufacturer involves evaluating several criteria

- Industry Experience Look for manufacturers with a proven track record in producing aging test chambers tailored for your specific industry. Experience often correlates with knowledge of the unique requirements for different materials.

- Technology and Innovation The best manufacturers invest in research and development to enhance their products with the latest technology, ensuring high reliability and precision in testing.

- Customer Support and Service A manufacturer that provides strong customer support, including installation, training, and maintenance, can significantly enhance your testing processes.

- Compliance with Standards Ensure that the manufacturer complies with industry standards such as ISO and ASTM, as this ensures the validity and reliability of the testing results.

Conclusion

Aging test chambers are indispensable tools for ensuring the reliability and longevity of materials across various industries. By accurately simulating aging conditions, these chambers provide critical insights that help manufacturers improve product quality and safety. When selecting an aging test chamber manufacturer, consider their expertise, technology, and support to ensure that you are investing in a reliable and effective solution for your testing needs. As industries continue to evolve, the role of aging test chambers in maintaining material integrity will only grow in importance.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

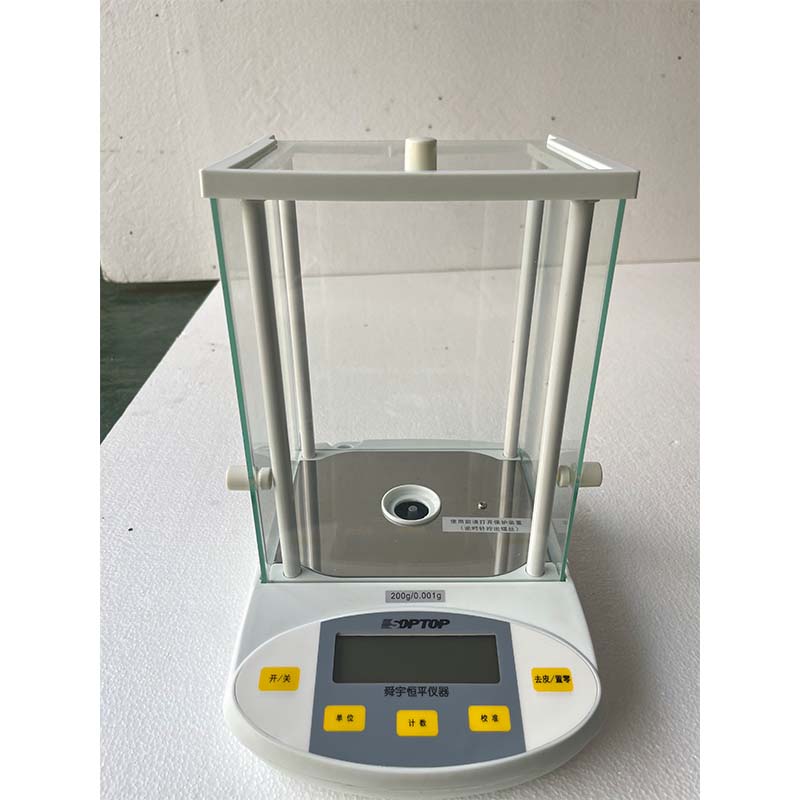

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy