Exporters of ASTM D412 Standard Tensile Testers for Accurate Material Testing Solutions

Understanding ASTM D412 and Its Importance in Tensile Testing

Tensile testing is an essential procedure in material science, particularly for materials such as rubber, plastics, and elastomers. Among the various standards that guide tensile testing, ASTM D412 stands out as a fundamental specification developed by ASTM International. This standard is specifically designed for the determination of the tensile properties of rubber, making it critical for manufacturers, quality control specialists, and researchers alike.

ASTM D412 Overview

ASTM D412 provides a comprehensive method for testing vulcanized rubber and thermoplastic elastomers. This standard outlines the procedures for the tensile testing of rubber materials, which includes the preparation of samples, the apparatus used, and the method for determining various tensile properties, including tensile strength, elongation at break, and modulus of elasticity.

The precise alignment and measurement during the tensile testing process ensure consistency in results, allowing manufacturers to assess the quality of their products reliably. The tensile tester conforming to ASTM D412 will evaluate how rubber behaves under tensile stress, measuring its ability to stretch before breaking.

The Importance of Tensile Testing

The tensile properties of rubber are crucial for various applications. These properties dictate how a rubber component will perform in real-world conditions. For instance, in the automotive industry, rubber seals and gaskets must withstand significant forces and remain functional under thermal and mechanical stresses. A thorough understanding of the tensile characteristics allows manufacturers to tailor their materials for specific applications, thereby enhancing performance and longevity.

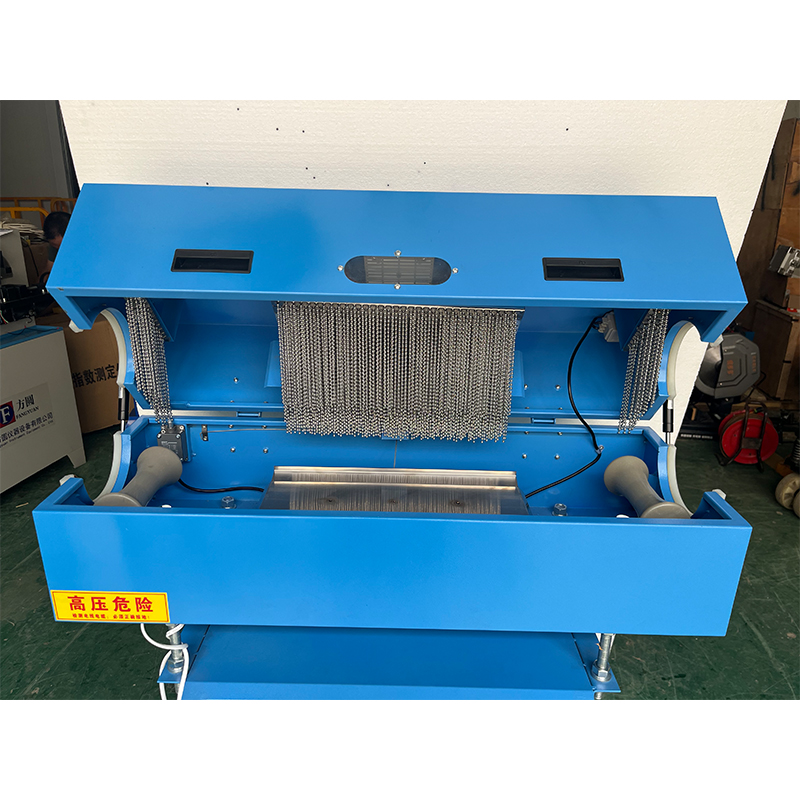

tensile tester astm d412 exporters

By adhering to the ASTM D412 standard, companies can ensure their products meet both industry requirements and consumer expectations. Accurate tensile testing helps in identifying defects early in the production process, ultimately reducing waste and costs associated with defective materials.

Exporting Tensile Testers

With the globalization of industry, the demand for reliable and precise tensile testing equipment continues to rise. Manufacturers of tensile testers that comply with ASTM D412 are finding growing opportunities in exporting these devices to markets worldwide. Exporters are focusing on crafting high-quality, durable tensile testers that not only meet ASTM standards but also incorporate advanced technology for enhanced precision.

These testers often feature digital displays, software integration for data analysis, and automation options that streamline the testing process. The continuous evolution of these tools fosters innovation, allowing manufacturers to achieve more accurate results and thereby improving the quality of their final products.

Conclusion

In conclusion, ASTM D412 is a vital standard that upholds the integrity of tensile testing in rubber and elastomer materials. Its significance goes beyond mere compliance; it plays a pivotal role in ensuring that manufacturers deliver products that meet rigorous performance standards. As the market for tensile testing equipment continues to expand, exporters of ASTM D412 compliant testers are crucial for supporting industries worldwide in their quest for quality assurance. Ensuring that products meet these essential standards not only bolsters consumer confidence but also enhances sustainability through reduced material waste and improved manufacturing processes.

In a world where material performance can mean the difference between success and failure, adhering to ASTM standards like D412 becomes a cornerstone of industrial integrity and innovation.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy