universal tensile testing machine factory

The Importance of Universal Tensile Testing Machines in Manufacturing

In today's competitive manufacturing landscape, ensuring the quality and durability of materials is paramount. One of the most critical tools in assessing material properties is the universal tensile testing machine (UTM). This essential piece of equipment plays a vital role in laboratories and production facilities, helping manufacturers understand the mechanical properties of materials, including their strength, ductility, and elasticity.

What is a Universal Tensile Testing Machine?

A universal tensile testing machine is designed to apply a controlled tensile load to a sample material until failure occurs. This process helps in determining the material's tensile strength, yield strength, elongation, and reduction in area. The machine can also conduct compression, bending, and shear tests, making it a versatile tool in material testing. Equipped with advanced software and data acquisition systems, UTMs can provide precise measurements and detailed reports that assist engineers and quality control professionals in making informed decisions.

Applications of Universal Tensile Testing Machines

UTMs are utilized across a wide range of industries, from aerospace to automotive, construction to textiles. In the aerospace sector, for example, rigorous testing of materials ensures that components can withstand extreme operating conditions. Similarly, in the automotive industry, testing the tensile properties of metals and composites helps in designing safer and more efficient vehicles.

In construction, analyzing the tensile strength of steel and concrete is crucial for structural integrity. Materials that fail to meet the required standards can lead to hazardous situations, making UTMs indispensable for compliance with safety regulations. Additionally, industries involved in textiles and plastics use UTMs to evaluate the performance of their materials under various conditions, ensuring that they can withstand everyday use.

The Manufacturing Process of Universal Tensile Testing Machines

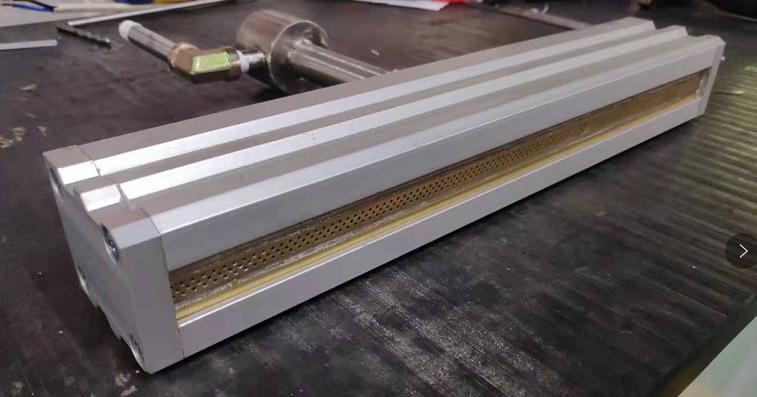

universal tensile testing machine factory

The fabrication of universal tensile testing machines involves precision engineering and stringent quality control. Manufacturers typically utilize high-quality materials such as steel and aluminum alloys to ensure the machine's durability and accuracy. Each machine undergoes a series of tests to examine its functionality, including calibration and validation against industry standards.

Modern UTMs are often equipped with computerized systems that automate data collection and analysis. Manufacturers focus on creating user-friendly interfaces that allow operators to easily set testing parameters, monitor the process in real-time, and generate comprehensive reports. The integration of advanced technologies, including digital load cells and extensometers, enhances the accuracy and reliability of the results, solidifying the UTM’s position as a cornerstone of material testing.

Selecting the Right Universal Tensile Testing Machine

When looking for a universal tensile testing machine, several factors need to be considered. First, determine the types of materials that will be tested and the required testing standards. Different machines are designed to handle varying loads and specimen sizes. Compact models are suitable for smaller laboratories, while larger, more robust machines are necessary for heavy-duty applications.

Moreover, consider the level of automation and data processing capabilities. Machines that offer advanced software solutions can significantly reduce the time spent on data analysis, allowing for quicker decision-making. Ensuring that the manufacturer provides excellent customer support and training can also enhance the operational efficiency of the testing process.

Conclusion

Universal tensile testing machines serve as an indispensable asset in the manufacturing and engineering sectors. Their ability to provide accurate and repeatable testing results ensures that materials meet or exceed industry standards, thereby enhancing product quality and safety. As technology continues to advance, the capabilities and applications of UTMs are expected to expand further, solidifying their role in driving innovation and maintaining high standards across various industries. Embracing these machines not only supports compliance with regulations but also fosters confidence in the products delivered to consumers.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy