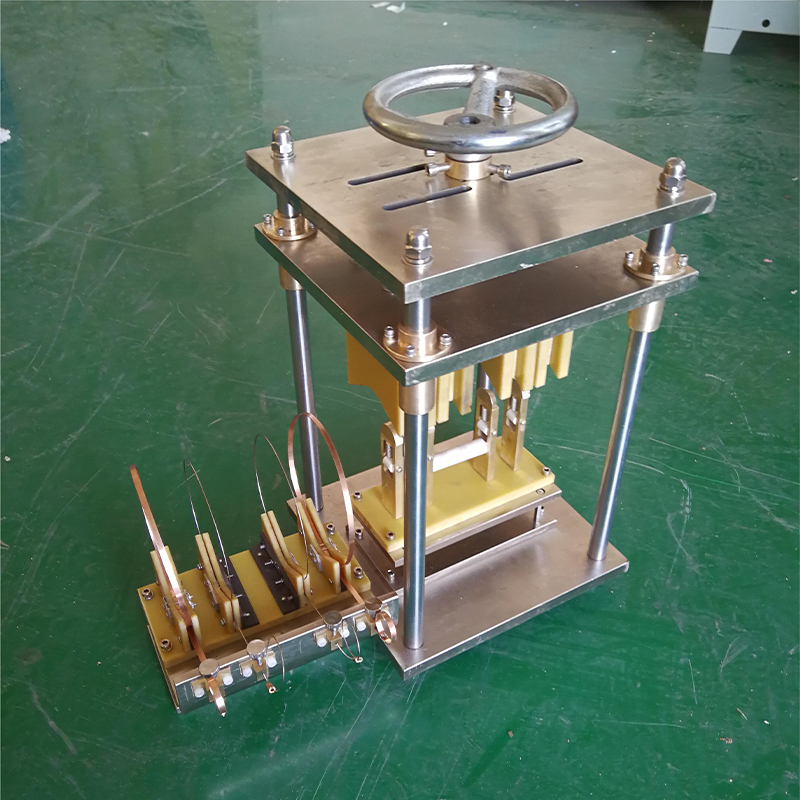

winding and torsion testing machine exporter

The Importance of Winding and Torsion Testing Machines in Modern Manufacturing

In the realm of advanced manufacturing, quality control is paramount. As industries push the boundaries of technology, ensuring the durability and reliability of materials becomes increasingly critical. One key player in this process is the winding and torsion testing machine, which is essential for evaluating the tensile strength and torsional characteristics of materials, particularly in industries such as aerospace, automotive, and construction.

Winding and torsion testing machines are designed to simulate real-world conditions that materials may encounter during their lifecycle. These machines are capable of subjecting samples to controlled winding and twisting forces, thereby providing insights into how the materials will behave under stress. The data garnered from these tests not only assists in compliance with industry standards but also plays a crucial role in the research and development of new materials.

One of the primary applications of winding and torsion testing machines is in the assessment of composite materials. Composites are commonly used in applications where lightweight yet durable materials are required. Testing these materials under specific winding and torsional loads allows manufacturers to determine their mechanical properties, such as stiffness, strength, and failure points. This information is invaluable for ensuring that the materials can withstand the extreme conditions they may face during their use.

winding and torsion testing machine exporter

Furthermore, these testing machines are crucial when it comes to quality assurance. Manufacturers can utilize the results from winding and torsion tests to identify any defects or weaknesses in their materials before they are put into production. This proactive approach not only saves time and resources but also enhances the overall safety and performance of the final products. Various industries, including the production of wires, cables, and fasteners, rely on these tests to ensure that their products meet stringent regulatory requirements.

In addition to their applications in product development and quality control, winding and torsion testing machines are also instrumental in academic research. Engineers and scientists use these machines to explore the mechanical properties of new materials, allowing for the continuous evolution of technology. Universities and research institutions often collaborate with manufacturers to gain access to cutting-edge testing equipment, fostering innovation in material science.

As the demand for high-performance materials grows, so does the importance of winding and torsion testing machines. Manufacturers are increasingly looking to exporters who specialize in these machines to meet their testing needs. These specialized machines must be tailored to the specific requirements of industries, ensuring that they can deliver accurate and repeatable results.

In conclusion, winding and torsion testing machines serve as critical tools in the manufacturing sector, ensuring that materials are not only robust but also reliable. With their ability to simulate real-world stresses and validate material properties, these machines play a vital role in maintaining quality assurance, driving innovation, and ultimately, delivering safe products to consumers. As industries continue to evolve, so will the technology surrounding testing machines, making them an indispensable part of modern manufacturing practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy