jan . 09, 2025 10:35

Back to list

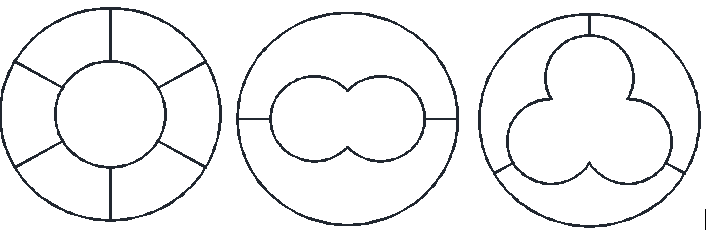

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

Wire and cable testing machines represent the pinnacle of precision, reliability, and safety in the electrical industry. These sophisticated devices are indispensable tools for manufacturers and quality assurance teams, ensuring the products meet stringent industry standards. Leveraging years of industry experience and professional expertise, let us delve into what makes wire and cable testing machines crucial for the industry and how businesses can utilize them to their full potential.

Trustworthiness in this context goes beyond the manufacturing of the testing machines themselves; it extends to the data they produce. Accurate and reliable test results are paramount for ensuring safety and efficacy in wire and cable applications, from household wiring systems to complex industrial networks. Manufacturers often highlight third-party verifications and certifications that attest to the reliability of their testing equipment, further reinforcing trust with end-users. When selecting a wire and cable testing machine, businesses should consider factors such as versatility, precision, and ease of use. Machines that offer a broad range of testing options can provide comprehensive insights in just one setup, thus optimizing workflow efficiency. Moreover, modern advancements have introduced automated testing solutions, minimizing human error and providing consistent data collection. User-friendly interfaces with detailed guide steps also allow operators, even those with minimal training, to perform complex testing procedures confidently. Incorporating wire and cable testing machines into a production line is not simply about adhering to compliance; it’s about safeguarding a reputation for quality and reliability. As technology advances and the complexity of electronic devices continues to grow, these machines will play an increasingly vital role in ensuring that wire and cable products are equipped to meet future demands. By investing in high-quality testing machines now, businesses affirm their commitment to excellence and build trust with stakeholders throughout their supply chain.

Trustworthiness in this context goes beyond the manufacturing of the testing machines themselves; it extends to the data they produce. Accurate and reliable test results are paramount for ensuring safety and efficacy in wire and cable applications, from household wiring systems to complex industrial networks. Manufacturers often highlight third-party verifications and certifications that attest to the reliability of their testing equipment, further reinforcing trust with end-users. When selecting a wire and cable testing machine, businesses should consider factors such as versatility, precision, and ease of use. Machines that offer a broad range of testing options can provide comprehensive insights in just one setup, thus optimizing workflow efficiency. Moreover, modern advancements have introduced automated testing solutions, minimizing human error and providing consistent data collection. User-friendly interfaces with detailed guide steps also allow operators, even those with minimal training, to perform complex testing procedures confidently. Incorporating wire and cable testing machines into a production line is not simply about adhering to compliance; it’s about safeguarding a reputation for quality and reliability. As technology advances and the complexity of electronic devices continues to grow, these machines will play an increasingly vital role in ensuring that wire and cable products are equipped to meet future demands. By investing in high-quality testing machines now, businesses affirm their commitment to excellence and build trust with stakeholders throughout their supply chain.

Next:

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy