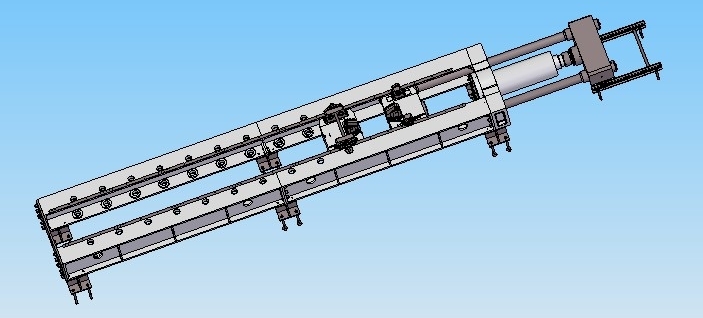

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Testing Machine

Mafotokozedwe Akatundu

TXWL-600 electro-hydraulic servo yopingasa kosunthika kuyezetsa makina utenga yopingasa chimango dongosolo, ndodo imodzi iwiri akuchita pisitoni yamphamvu amayesa mphamvu, ndi dongosolo kulamulira kompyuta amazindikira kulamulira basi ya ndondomeko mayeso ndi kulamulira servo valavu ndi zigawo zina, mayeso Deta imasonkhanitsidwa molondola ndi sensa yonyamula katundu ndikutumizidwa ku kompyuta, dongosololi limangosanthula, kukonza ndikusunga zotsatira zoyeserera, ndipo chosindikizira akhoza kusindikiza mwachindunji lipoti loyeserera. Makinawa amagwiritsidwa ntchito makamaka poyesa kuyesa kwachitsulo chachitsulo, ndi kupanga zamakono za kafukufuku wa sayansi ndi kuphunzitsa ndi mafakitale ena kuti akwaniritse zofunikira za zida zoyesera zabwino.

Kufotokozera Kwamakina

1.Host system

Gawo lalikulu la makinawo limapangidwa makamaka ndi chimango chachikulu cha makina, mpando wa silinda yamafuta, silinda yamafuta, mtengo wosuntha, mpando wakutsogolo ndi kumbuyo kwa chuck ndi sensor yonyamula katundu. Itha kuchita mayeso amphamvu ndi katundu wambiri wa 600kN pazatsanzo.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Malo oyesera ali ndi chivundikiro chotetezera, chomwe chingateteze bwino chitetezo cha ogwira ntchito.

2.Oil source system

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Gawo lamagetsi

Kuwongolera kwamagetsi kumakonzedwa m'malo oyeserera, ndipo pali gulu lopangidwira mwapadera kuti ntchito zamitundu yonse zizimveka bwino pang'onopang'ono. Zida zamagetsi ndi zamtundu wotchuka wapadziko lonse lapansi, zogwira ntchito mokhazikika komanso zodalirika.

Pulogalamu yamapulogalamu:

(1) Kutengera nsanja ya Windows XP yokhala ndi magwiridwe antchito, kuwongolera mphamvu zoyeserera zofananira, kusamutsidwa kofanana, kugwirizira mphamvu yoyeserera, kusamutsidwa ndi njira zina zoyeserera zitha kuphatikizidwa mwakufuna kukwaniritsa zofunikira za njira zosiyanasiyana zoyesera. mpaka pamlingo waukulu, ndikuzindikira mawonetsedwe osiyanasiyana a data, kujambula pamapindikira, kukonza deta, kusungirako ndi kusindikiza ntchito zofunika pakuyesa.

(2) Tumizani chizindikiro chowongolera ku valavu ya servo kudzera pakompyuta kuti muwongolere kutsegula ndi kuwongolera kwa valavu ya servo, potero kuwongolera kutuluka mu silinda, ndikuzindikira kuwongolera kwamphamvu yoyeserera yofanana, kusamuka kofanana, ndi zina zambiri. .

(3) Wokhala ndi mipukutu iwiri yotseka yoyeserera yamphamvu yoyeserera ndi kusamuka.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Mawonekedwe akuluakulu ali ndi ntchito zonse za ntchito ya tsiku ndi tsiku ya mayesero, monga kulowetsa chidziwitso chachitsanzo, kusankha zitsanzo, kujambula kokhotakhota, kuwonetseratu deta, kukonza deta, kusanthula deta, kuyesa kuyesa, ndi zina zotero. kudya.

(6) Deta ikhoza kutulutsidwa kwa chosindikizira kuti asindikize lipoti la mayeso.

(7) Kasamalidwe kaulamuliro wadongosolo, magawo amachitidwe onse ali otseguka kwa ogwiritsa ntchito akatswiri, kuwonetsetsa kusinthasintha ndi kudalirika kwa dongosolo.

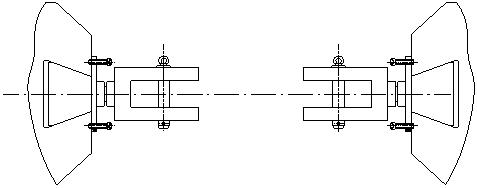

4.Yesani Chalk

Zokhala ndi zida zoyesera zingwe (onani m'munsimu) ndi zowonjezera zina zimapangidwa molingana ndi mulingo woperekedwa ndi wogwiritsa ntchito kapena zofunikira zachitsanzo.

5.Zida Zoteteza Chitetezo

(1) Chitetezo chochulukirachulukira pamene mphamvu yoyesera idutsa 2% mpaka 5% ya mphamvu yoyesera kwambiri kapena mtengo wokhazikitsidwa.

(2) Chitetezo cha sitiroko pamene pisitoni ikupita kumalo omaliza.

(3) Ndi kutentha kwa mafuta, mulingo wamadzimadzi komanso chitetezo chamafuta ndi zida zowonetsera.

(4) Malo oyesera ali ndi chivundikiro chotetezera kuti sampuli isasweke ndi kugwa.

(5) Pakachitika ngozi, dinani batani loyimitsa mwadzidzidzi pa kabati yowongolera mwachindunji

Technical Parameter

1.Maximum test force: 600kN

2.Kuyesa mphamvu kuyeza osiyanasiyana: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4. Malo oyeserera (kupatula pisitoni sitiroko): 20mm ~ 12000mm

5.Piston sitiroko: 1000mm

6.Kuthamanga kwakukulu kwa pistoni: 100 mm / min

7.Deformation extensometer yolondola: 0.01mm

8.Kukula kwa makina akuluakulu (mm): 16000 (L) x 1300 (W) x 1000 (H) (kupatula chophimba choteteza)