hydraulic conductor resistance fixture

Hydraulic Conductor Resistance Fixture Understanding Its Importance and Application

In the realm of fluid mechanics and hydraulic engineering, the efficiency of hydraulic systems relies heavily on the effective transmission of fluids. Central to this efficiency is the concept of hydraulic conductor resistance, which significantly impacts the performance of hydraulic systems. To study and optimize this resistance, engineers have developed hydraulic conductor resistance fixtures designed expressly for testing and analyzing the behavior of fluids in various conditions.

What is Hydraulic Conductor Resistance?

Hydraulic conductor resistance refers to the opposition that a fluid encounters as it flows through a conduit, whether it be a pipe, hose, or another type of hydraulic conductor. This resistance is influenced by several factors, including the fluid's viscosity, the diameter and length of the conduit, surface roughness, and flow velocity. Understanding these dynamics is crucial for designing systems that require precise flow control, such as hydraulic circuits in heavy machinery, automotive systems, and aerospace applications.

Purpose of Hydraulic Conductor Resistance Fixtures

Hydraulic conductor resistance fixtures serve as vital tools in characterizing the resistive properties of various conductor materials. These fixtures allow for controlled testing of fluid flow under standardized conditions, enabling engineers to measure how different factors affect resistance. By using these fixtures, practitioners can obtain empirical data that informs the design and optimization of hydraulic systems.

Design and Functionality of the Fixture

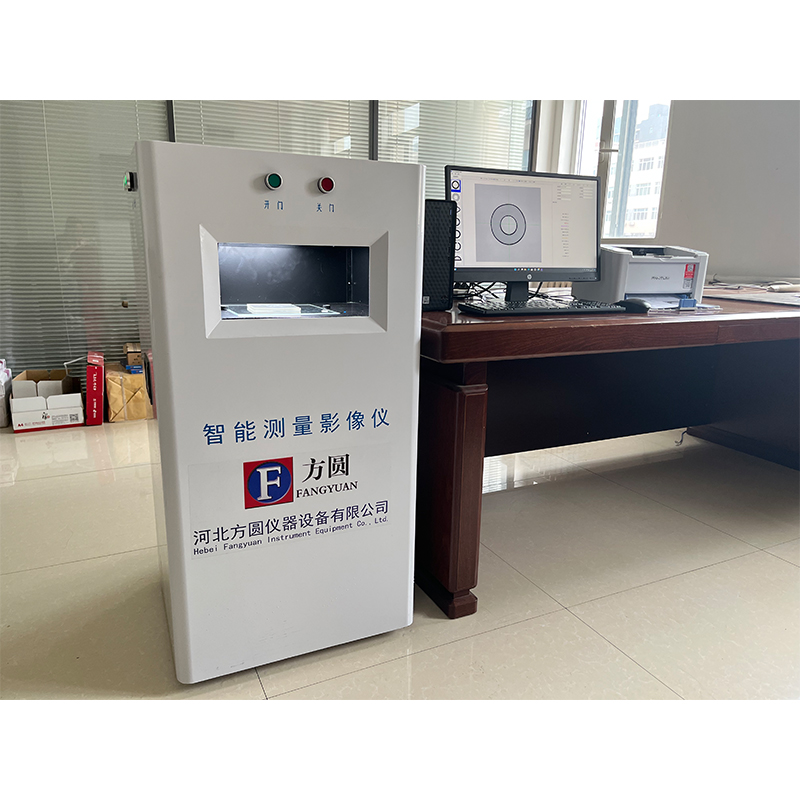

hydraulic conductor resistance fixture

A typical hydraulic conductor resistance fixture consists of a flow loop that includes a pump, pressure gauges, flow meters, and various sections of hydraulic conductors. The design often allows for easy interchangeability of different conductor types, facilitating comparative studies. The flow of fluid is controlled and measured accurately, providing essential data that can be analyzed to determine the resistance characteristics of the materials and configurations being tested.

During testing, engineers can manipulate key parameters such as input pressure, flow rate, and fluid type. This versatility makes hydraulic conductor resistance fixtures invaluable in a research and development setting. Additionally, many fixtures are equipped with advanced sensors and data acquisition systems that enable real-time monitoring of flow characteristics and pressure differentials.

Applications of Hydraulic Conductor Resistance Testing

The applications of hydraulic conductor resistance testing are extensive across various industries. In automotive engineering, for instance, optimizing hydraulic lines can lead to improvements in braking systems, steering mechanisms, and suspension systems. In aerospace engineering, where weight and efficiency are crucial, understanding hydraulic resistance can help in developing lightweight but robust hydraulic systems.

Moreover, these fixtures play a significant role in research. Academic institutions and laboratories utilize hydraulic conductor resistance fixtures to explore new materials and designs, often leading to innovations that can dramatically improve performance and efficiency in hydraulic systems.

Conclusion

In summary, hydraulic conductor resistance fixtures are critical in the analysis and optimization of fluid dynamics within hydraulic systems. By providing a controlled environment for testing, these fixtures enable engineers to understand the resistance phenomena associated with various hydraulic conductors. As industries continue to evolve and demand more efficient and reliable hydraulic systems, the importance of these testing fixtures will only grow. Their role in the design and application of hydraulic systems underscores a commitment to innovation and excellence in engineering practices. Properly leveraging the insights gained from these fixtures can lead to significant advancements, ensuring that hydraulic systems function efficiently and reliably in diverse applications.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy