hydraulic resistance clamp supplier

Understanding Hydraulic Resistance Clamps The Importance of Choosing the Right Supplier

Hydraulic systems are the backbone of many industrial applications, from manufacturing to construction. In these systems, maintaining stable pressure and flow is critical, and one key component that facilitates this is the hydraulic resistance clamp. Understanding the role of these clamps and selecting the right supplier is essential for ensuring system reliability and efficiency.

What Are Hydraulic Resistance Clamps?

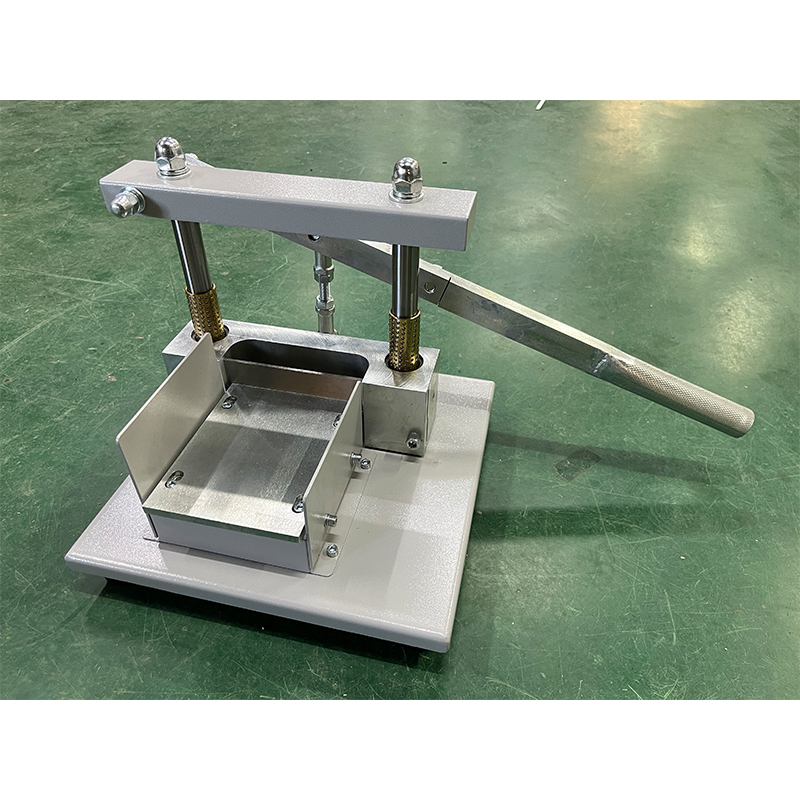

Hydraulic resistance clamps are devices used to secure hoses or tubing within a hydraulic system, ensuring that they maintain their position under high-pressure conditions. These clamps are designed to withstand the forces exerted on them during operation while preventing leaks that can compromise performance and safety. The primary function of hydraulic resistance clamps is to provide stability and durability to the hydraulic lines, which in turn enhances overall system efficiency.

The Importance of Quality

When it comes to hydraulic systems, the quality of components cannot be overlooked. Poor quality clamps can lead to failures, which can be costly in terms of repairs and lost productivity. For this reason, sourcing high-quality hydraulic resistance clamps from reputable suppliers is essential. A trusted supplier will provide clamps that are rigorously tested for durability, pressure resistance, and other operational requirements.

Factors to Consider When Choosing a Supplier

1. Experience and Reputation One of the first things to assess when selecting a supplier is their experience in the industry and their reputation. A supplier with a long history of producing hydraulic components is often more reliable than newer entrants. Online reviews, industry referrals, and case studies can provide insight into a supplier's credibility.

hydraulic resistance clamp supplier

2. Product Range Hydraulic systems often require various components and types of clamps. A supplier offering a comprehensive product range allows for easier sourcing and compatibility across products. Look for suppliers who can provide not only hydraulic resistance clamps but also hoses, fittings, and other hydraulic components.

3. Customization Options Every hydraulic application is unique, and sometimes standard clamps may not meet specific requirements. A good supplier should offer customization options to meet your exact specifications, whether in terms of size, material, or design.

4. Quality Assurance Ensure that the supplier adheres to stringent quality assurance processes. This may include certifications such as ISO standards, which signify that the supplier maintains high manufacturing standards. Ask about testing protocols that the clamps undergo before reaching the market.

5. Customer Support and Services Effective communication and support are essential when dealing with suppliers. A reputable supplier should offer robust customer service to address any inquiries or issues. After-sales support is also vital should any problems arise post-purchase.

6. Pricing and Payment Terms While cost is an important factor, it should not be the sole consideration. Compare pricing across various suppliers, but ensure you are also factoring in quality and service. Additionally, inquire about payment terms, bulk order discounts, and any warranties offered.

7. Delivery and Lead Times Time is often of the essence in hydraulic applications, especially during emergencies or project deadlines. Check the supplier’s lead times for delivery and their ability to fulfill orders promptly.

Conclusion

Choosing the right supplier for hydraulic resistance clamps is critical for the efficiency and reliability of your hydraulic system. By considering factors such as experience, product range, customization, and quality assurance, you can find a supplier that not only meets your needs but also becomes a valuable partner in your operations. Investing time in selecting a quality supplier will ultimately lead to improved performance, enhanced safety, and reduced costs in the long-term management of hydraulic systems. As the demand for hydraulic applications continues to grow, ensuring that you work with a reputable supplier is more important than ever.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy