Cable Bundled Burning Test Equipment Suppliers and Manufacturers Overview

The Importance of Cable Bunched Burning Test Equipment in Safety Compliance

In the modern world, where numerous electrical systems are being installed in public and private buildings, ensuring safety and compliance with rigorous fire standards is of utmost importance. One critical aspect of this compliance is the testing of cables, particularly in bunched configurations. This article focuses on the significance of cable bunched burning test equipment, the methods used, and manufacturers that are leading the charge in providing this essential technology.

Understanding Cable Bunched Burning Tests

Cable bunched burning tests are designed to evaluate the fire performance of electrical cables when they are assembled in a tight configuration, typically as they would be installed in real-world scenarios. The primary concern is that when cables are bunched together, the heat generated by one cable can easily ignite adjacent cables, leading to a rapid spread of flames. Manufacturers and regulatory bodies require standardized testing to ensure that cables can withstand such conditions without contributing to the spread of fire.

The tests generally involve subjecting a bundle of cables to controlled flame exposure, then monitoring the ignition, spread of flames, and smoke production. The results of these tests are critical for manufacturers, allowing them to develop cables that meet safety standards while minimizing fire risks.

The Role of Manufacturers

To conduct these tests accurately, high-quality test equipment is essential. There are several manufacturers recognized for producing reliable cable bunched burning test equipment. These manufacturers invest in research and development to ensure their equipment not only meets current safety standards but also adapts to new regulations as they emerge.

Leading equipment manufacturers often utilize advanced technologies such as digital monitoring systems, which ensure accurate data collection during the tests. This includes real-time monitoring of temperature, smoke density, and flame spread. By integrating these technologies, manufacturers can provide more detailed reports to their clients, ensuring they meet both national and international fire safety standards.

Key Features of Quality Testing Equipment

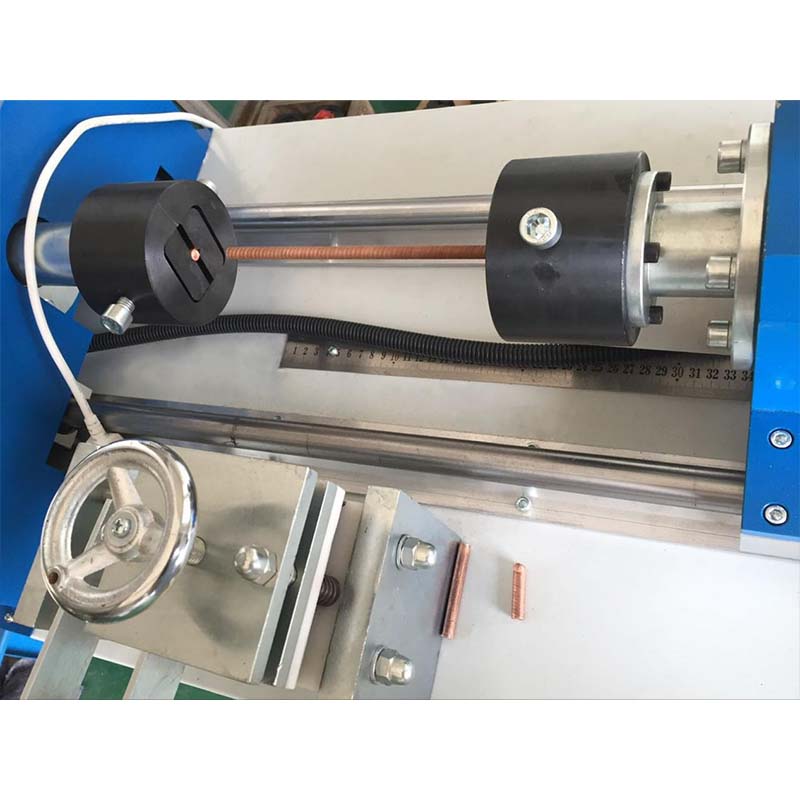

cable bunched burning test equipment manufacturer

When looking for cable bunched burning test equipment, several features should be considered. Firstly, the equipment should conform to recognized tests such as the British Standard (BS), International Electrotechnical Commission (IEC), or Underwriters Laboratories (UL) standards. The precision of the test apparatus is crucial in producing reliable results.

Secondly, ease of use is fundamental. Modern test equipment often includes user-friendly interfaces that allow operators to set up tests quickly and efficiently. Automation in data logging and interpretation can significantly reduce human error and provide a streamlined approach to testing.

Thirdly, the durability and safety of the equipment is paramount. Given that testing involves high temperatures and potentially hazardous situations, the design and materials used in the construction of the equipment must ensure the safety of the operators.

Global Standards and Regulations

Across the globe, various regulations mandate the testing of electrical cables. Countries may have different standards, but the underlying principle remains the same to protect lives and property from the dangers posed by fire. In Europe, the Construction Products Regulation (CPR) outlines the parameters for cable testing, while the National Fire Protection Association (NFPA) sets codes in the United States. Manufacturers of cable bunched burning test equipment must stay abreast of these regulations to ensure compliance.

Conclusion

As the demand for safe electrical systems continues to rise, the role of cable bunched burning test equipment becomes increasingly significant. By ensuring that cables can withstand the rigors of real-world conditions without exacerbating fire risks, manufacturers play a crucial role in enhancing safety standards. Those considering investment in testing equipment should prioritize quality, precision, and compliance with current regulations. With continuous advancements in technology, the future of cable testing looks promising, ultimately contributing to safer built environments for all.

In summary, the importance of cable bunched burning test equipment can’t be overstated. Whether you are a manufacturer or a regulatory body, understanding the intricacies of this testing is key to protecting lives and property from the devastating effects of fire.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy