custom semi-conductive test fixture

Custom Semi-Conductive Test Fixture Enhancing Precision in Electronic Testing

In the fast-evolving world of electronics, the demand for high-performance components is ever-increasing. At the heart of this demand lies the necessity for reliable testing methods, particularly for semiconductors. A custom semi-conductive test fixture plays a pivotal role in ensuring that semiconductor devices meet stringent performance and reliability standards. This article delves into the importance of these fixtures, their design considerations, and their impact on testing efficiency.

What is a Custom Semi-Conductive Test Fixture?

A semi-conductive test fixture is a specialized apparatus used to test semiconductor components under various operating conditions. These fixtures are designed to facilitate electrical connections between the semiconductor device and testing equipment while ensuring the integrity and accuracy of the results. Customization is essential in this context, as different semiconductor devices have unique specifications, including size, pin configuration, and testing requirements.

Importance of Customization

The customization of test fixtures is crucial for several reasons. First, it enables precise alignment and contact between the device under test (DUT) and the testing equipment, thereby minimizing the risk of measurement errors. Additionally, a custom fixture can accommodate specific thermal management solutions, which are essential for high-power semiconductor devices that generate significant heat during operation.

Moreover, custom fixtures can be designed to support a variety of testing methods, such as DC, AC, and high-frequency testing, thus enhancing their versatility. This adaptability is vital as manufacturers often need to conduct different types of tests throughout the product development and production phases.

custom semi-conductive test fixture

Design Considerations

When designing a custom semi-conductive test fixture, several factors must be considered. Material selection is critical since the fixture must withstand repeated use and provide reliable performance over time. The materials chosen should also be compatible with the environmental conditions and chemical exposure related to the specific testing process.

Another critical aspect is the user-friendliness of the fixture. A well-designed test fixture not only streamlines the testing process but also enhances safety for operators. Features like easy access for device insertion, robust locking mechanisms, and clear labeling of connections can significantly improve the operational efficiency and reliability of the testing process.

Impact on Testing Efficiency

The implementation of a custom semi-conductive test fixture can lead to substantial improvements in testing efficiency. By reducing the time taken to set up tests and enhancing the accuracy of measurements, these fixtures can help semiconductor manufacturers accelerate their product development cycles. Furthermore, the reduction in testing errors contributes to higher yields and lower production costs, ultimately benefiting both manufacturers and consumers.

In conclusion, custom semi-conductive test fixtures are integral to the semiconductor testing process. They provide the precision, adaptability, and efficiency required to ensure that semiconductor devices perform optimally. As technology continues to advance, the role of these custom fixtures will become increasingly critical in maintaining the quality and reliability of electronic components.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

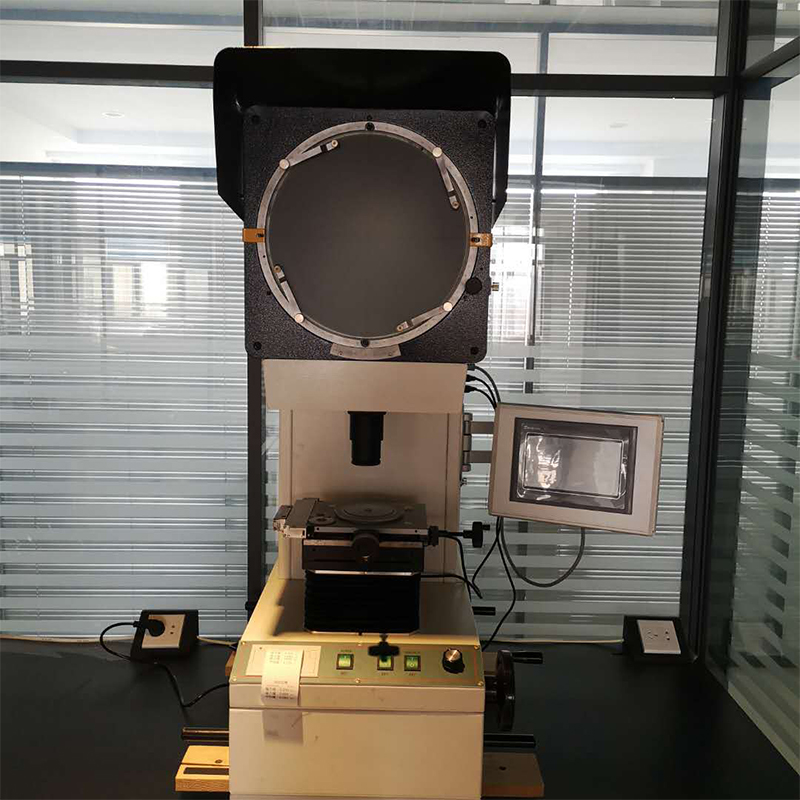

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy